High productivity pp hollow board extrusion line

Date:2021/6/7 11:21:23 / Read: / Source:This website

A high productivity polypropylene (PP) hollow board extrusion line is a specialized manufacturing system designed to efficiently produce lightweight, rigid PP boards with a hollow internal structure.

The key features of a high productivity PP hollow board extrusion line include:

1. High Output Capacity:

- These systems are engineered to achieve very high production rates, often in the range of 500-1500 kg per hour.

- This is enabled by powerful extruders, optimized die designs, and high-speed downstream processing.

2. Multi-Layer Extrusion:

- The extrusion dies are capable of producing boards with multiple layers, including inner and outer solid skins with a hollow core.

- This creates a lightweight but strong board structure.

3. Advanced Cooling Systems:

- Rapid cooling of the extruded board is crucial to maintain dimensional stability and mechanical properties.

- Specialized cooling systems, such as air knives and water baths, are employed.

4. High-Speed Cutting and Handling:

- Automated high-speed saws and stacking systems are used to efficiently cut and stack the extruded boards.

- Robotic material handling further improves productivity.

5. Process Control and Monitoring:

- Sophisticated control systems monitor and optimize key parameters like melt temperature, pressure, and line speed.

- This ensures consistent product quality and maximizes uptime.

The primary applications for PP hollow board produced on these high productivity lines include:

- Packaging and displays

- Furniture and construction materials

- Automotive components

- Industrial and agricultural applications

By leveraging advanced extrusion technology, these systems enable manufacturers to meet growing market demands for lightweight, durable, and cost-effective PP boards.

high productivity pp hollow board extrusion line data

Machine type

Sheet width(mm)

Sheet thickness(mm)

Max.Extrusion capacity(KG/H)

1400

1250

2-6 6-12 12-18

280/280/350

1800

1650

2-6 6-12 12-18

320/350/420

2300

2150

2-6 6-12

350/350

2400

2200

2-6 6-12

450

2600

2450

2-6 6-12

480

2800

2600

2-6 6-12

500

|

high productivity pp hollow board extrusion line |

Unit |

|

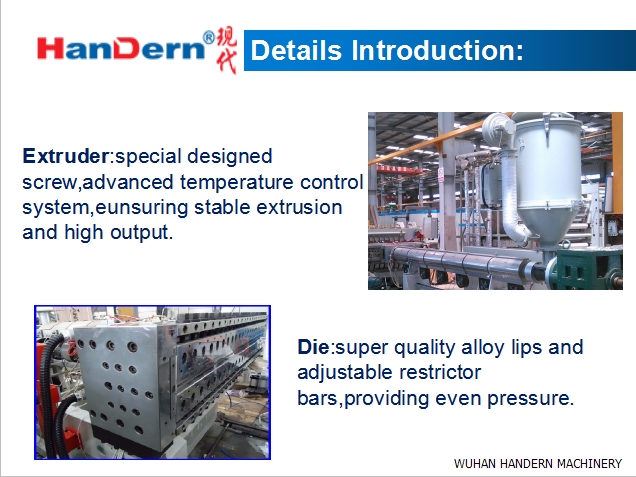

Single Screw Extruder |

one set |

|

Die |

one set |

|

Hydraulic Pressure Screen Changer |

one set |

|

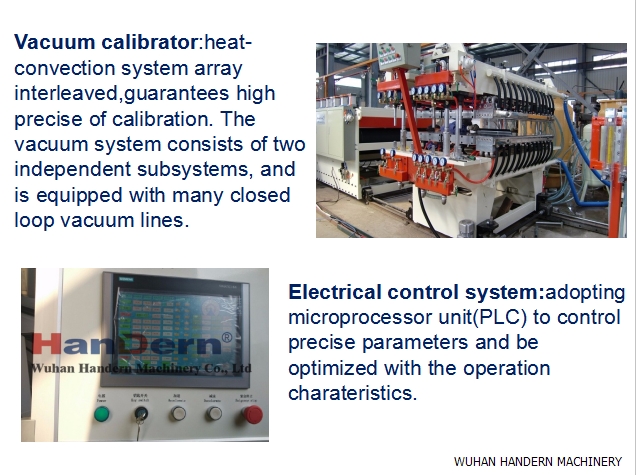

Vaccum Calibration Table |

one set |

|

First Haul-off |

one set |

|

Oven |

one set |

|

Cooling Device |

one set |

|

Second haul-off |

one set |

|

Cutting device |

one set |

|

Electrical Control Cabinet |

one set |

|

Stacker |

one set |

|

Screw Loader |

one set |

The configuration of machines can be CUSTOMIZED according to your needs!

high productivity pp hollow board extrusion line main Applications:

industrial packaging, electronic circulating box, auto part circulating box, logistics circulating box etc

delivery packaging:

PP turnover container box, PP corrugated packaging box, PP turnover packaging box,Plastic fire-retarding packaging box for food, electrionic or delivery industry.

Advertisement displayed card,billboard,light box etc.

Home temporary partition,wall backplate,ceiling board etc.

Other applications backplate of washing machine,cars,and water heater,baseplate for delivery etc

.

Packaging and shipping:

Seaworthy packing material such as:Wooden case and PE film,etc for PP plastic polypropylene hollow sheet machine package.

Author:admin