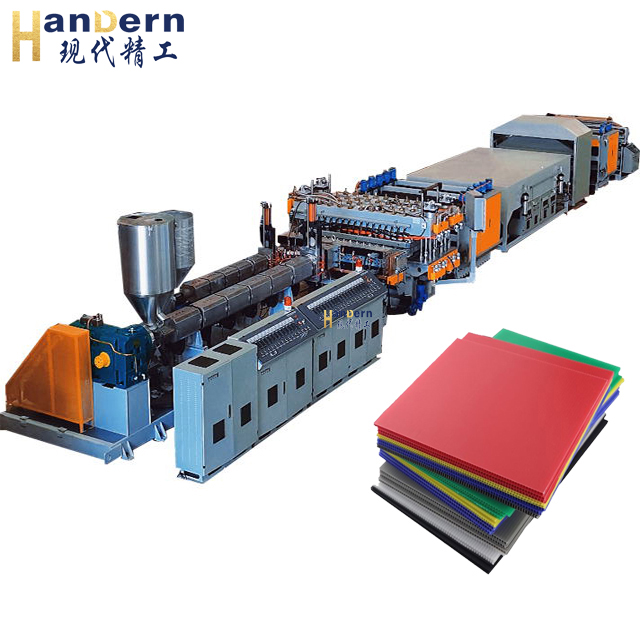

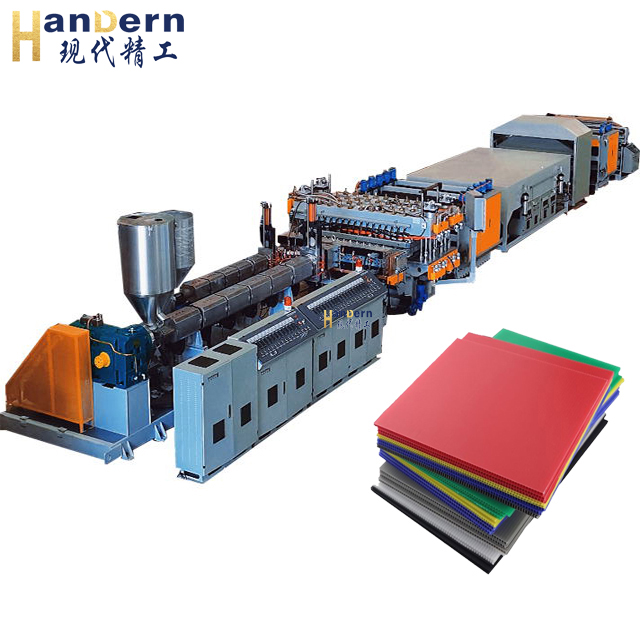

How to correctly set up and use PP hollow board production equipment

DATE:2025/1/13 10:28:47 / READ: / SOURCE:This station

Correctly setting up and using PP (polypropylene) hollow board production equipment is the key to ensuring production efficiency and product quality. The following is a detailed guide for setting up and using PP hollow board production equipment.

1. Equipment installation and debugging

1. Equipment installation and debugging

Before producing PP hollow boards, it is necessary to first install and debug the equipment reasonably. Ensure that the production line is in a horizontal position to avoid vibration and noise caused by unevenness of the equipment. The various parts of the equipment (such as extruders, molds, cooling systems, etc.) need to be properly connected to ensure no oil or gas leakage. After installation, conduct an air to load test to ensure that all parts are running properly and adjust parameters to achieve optimal performance.

2. Raw material preparation

The production of PP hollow boards requires high-quality PP resin and other additives (such as lubricants, coloring agents, etc.). Before setting up production equipment, it is necessary to inspect the raw materials to ensure that they meet production requirements. At the same time, cut or process raw materials as needed to ensure smooth flow in the feeding system and avoid production problems caused by uneven particle size.

3. Temperature and pressure settings

Before starting the device, it is necessary to set the appropriate temperature and pressure. The processing temperature of PP is usually between 160 ° C and 210 ° C, but the specific temperature needs to be adjusted according to the brand and model of PP resin used. The temperature of each section of the extruder screw (feeding area, plasticizing area, and metering area) should be set sequentially to ensure that the material can be uniformly plasticized. At the same time, check the equipment pressure to ensure that it is within a reasonable range and to avoid human caused damage to the equipment or product defects.

4. Mold and Forming

4. Mold and Forming

The mold is the key to the production of PP hollow boards, and it is necessary to ensure the cleanliness and reasonable adjustment of the mold. Before starting production, adjust the clearance and temperature of the mold to obtain uniform hollow plate thickness. Usually, it is advisable to maintain the mold temperature between 40 ° C and 70 ° C to effectively cool during the molding process and prevent product warping or deformation.

5. Configuration of cooling system

Cooling is crucial after extrusion molding. The cooling system generally adopts water cooling or air cooling. It is necessary to ensure uniform and timely cooling to avoid stress concentration in the hollow board caused by rapid cooling. The cooling effect can be optimized by adjusting the cooling water temperature and flow rate to ensure that the product is fully formed before cutting.

6. Operation observation and adjustment

In normal production, the operation of equipment, including temperature, pressure, production speed, and product quality, should be continuously observed. If abnormal situations are found (such as increased resistance, unstable temperature, etc.), production parameters should be adjusted in a timely manner. Record some common faults for quick identification and resolution.

Correctly setting up and using PP hollow board production equipment is not only crucial for improving production efficiency, but also directly related to the quality of the final product. Through reasonable equipment installation, parameter setting, monitoring operation, and regular maintenance, the efficient and stable operation of the PP hollow board production line can be ensured, creating greater economic benefits for the enterprise. Ensuring that technicians receive appropriate training to understand these important aspects in operation will help to successfully complete production tasks.

Correctly setting up and using PP hollow board production equipment is not only crucial for improving production efficiency, but also directly related to the quality of the final product. Through reasonable equipment installation, parameter setting, monitoring operation, and regular maintenance, the efficient and stable operation of the PP hollow board production line can be ensured, creating greater economic benefits for the enterprise. Ensuring that technicians receive appropriate training to understand these important aspects in operation will help to successfully complete production tasks.

Before producing PP hollow boards, it is necessary to first install and debug the equipment reasonably. Ensure that the production line is in a horizontal position to avoid vibration and noise caused by unevenness of the equipment. The various parts of the equipment (such as extruders, molds, cooling systems, etc.) need to be properly connected to ensure no oil or gas leakage. After installation, conduct an air to load test to ensure that all parts are running properly and adjust parameters to achieve optimal performance.

2. Raw material preparation

The production of PP hollow boards requires high-quality PP resin and other additives (such as lubricants, coloring agents, etc.). Before setting up production equipment, it is necessary to inspect the raw materials to ensure that they meet production requirements. At the same time, cut or process raw materials as needed to ensure smooth flow in the feeding system and avoid production problems caused by uneven particle size.

3. Temperature and pressure settings

Before starting the device, it is necessary to set the appropriate temperature and pressure. The processing temperature of PP is usually between 160 ° C and 210 ° C, but the specific temperature needs to be adjusted according to the brand and model of PP resin used. The temperature of each section of the extruder screw (feeding area, plasticizing area, and metering area) should be set sequentially to ensure that the material can be uniformly plasticized. At the same time, check the equipment pressure to ensure that it is within a reasonable range and to avoid human caused damage to the equipment or product defects.

The mold is the key to the production of PP hollow boards, and it is necessary to ensure the cleanliness and reasonable adjustment of the mold. Before starting production, adjust the clearance and temperature of the mold to obtain uniform hollow plate thickness. Usually, it is advisable to maintain the mold temperature between 40 ° C and 70 ° C to effectively cool during the molding process and prevent product warping or deformation.

5. Configuration of cooling system

Cooling is crucial after extrusion molding. The cooling system generally adopts water cooling or air cooling. It is necessary to ensure uniform and timely cooling to avoid stress concentration in the hollow board caused by rapid cooling. The cooling effect can be optimized by adjusting the cooling water temperature and flow rate to ensure that the product is fully formed before cutting.

6. Operation observation and adjustment

In normal production, the operation of equipment, including temperature, pressure, production speed, and product quality, should be continuously observed. If abnormal situations are found (such as increased resistance, unstable temperature, etc.), production parameters should be adjusted in a timely manner. Record some common faults for quick identification and resolution.

Author:admin