How is the quality grade of plastic hollow universal panel divided

DATE:2025/1/17 10:22:54 / READ: / SOURCE:This station

As an important lightweight building material, the classification of the quality level of plastic hollow universal panel is mainly based on the physical and chemical properties of the production material, the structural performance of the board, and its usability. The following are the main classification standards and influencing factors for the quality grade of plastic hollow universal panel.

1. Quality of raw materials

1. Quality of raw materials

The quality grade of plastic hollow universal panel is closely related to the selection of raw materials. The commonly used raw materials include polypropylene (PP) and polyethylene (PE), whose quality directly determines the performance of Wantong board. For example, high-quality polypropylene typically has better impact resistance, toughness, and heat resistance. The melt index (MFR), color, purity and other characteristics of raw materials are important indicators for dividing quality grades.

2. Physical performance testing

The physical properties are an important basis for dividing the quality grade of plastic hollow universal panels, mainly including the following aspects:

Tensile strength: The maximum stress at which a test sample is stretched, indicating the strength and load-bearing capacity of the material. Wan Tong boards with higher quality grades usually have higher tensile strength.

Impact strength: refers to the ability of a sample to resist damage when subjected to impact, which can reflect the toughness of plastic sheets. High grade products should have superior impact strength and be suitable for various complex environments.

Bending strength: It is crucial for evaluating the rigidity and load-bearing capacity of materials, especially in building applications.

3. Chemical performance evaluation

3. Chemical performance evaluation

In addition to physical properties, the chemical resistance of plastic hollow universal panels is also a key factor in dividing quality levels. The tolerance of products of different grades to different chemical media (such as acids, bases, salts, etc.) varies. High grade products are generally able to resist the erosion of various chemicals and are suitable for a wider range of applications.

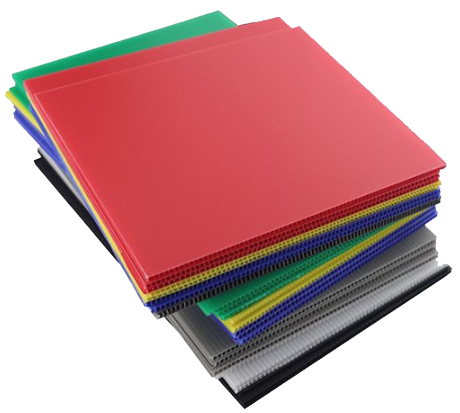

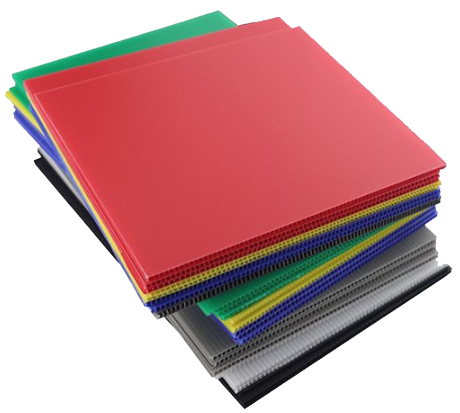

4. Appearance quality

The appearance quality also plays an important role in the market competition of Wantong board. The product should have a smooth surface, without obvious scratches, bubbles, uneven color defects. The appearance quality directly affects the aesthetic appeal and market recognition of the product. Generally, products with better appearance quality have higher quality levels.

5. Dimensional deviation

The dimensional accuracy of a product is also an important criterion for evaluating its quality level. The thickness, length, and width of plastic hollow universal panels must comply with national or industry standards. Excessive dimensional deviation may affect installation and usage effectiveness, therefore, strict control of dimensional accuracy is necessary during the production process.

6. Standards and Certification

6. Standards and Certification

In practical applications, the quality grade of plastic hollow universal panels is usually classified according to national standards (such as GB, ISO, etc.). At the same time, many production enterprises also obtain specific certifications, such as CE mark, ISO9001 quality management system certification, etc., as the basis for quality assurance.

7. Application Fields

Plastic hollow universal panels of different quality levels are suitable for different engineering projects. For example, high-grade products are usually used for high demand applications such as building exterior walls and partitions, while low-grade products can be used for temporary or low demand projects.

The quality grade of plastic hollow universal panel is closely related to the selection of raw materials. The commonly used raw materials include polypropylene (PP) and polyethylene (PE), whose quality directly determines the performance of Wantong board. For example, high-quality polypropylene typically has better impact resistance, toughness, and heat resistance. The melt index (MFR), color, purity and other characteristics of raw materials are important indicators for dividing quality grades.

2. Physical performance testing

The physical properties are an important basis for dividing the quality grade of plastic hollow universal panels, mainly including the following aspects:

Tensile strength: The maximum stress at which a test sample is stretched, indicating the strength and load-bearing capacity of the material. Wan Tong boards with higher quality grades usually have higher tensile strength.

Impact strength: refers to the ability of a sample to resist damage when subjected to impact, which can reflect the toughness of plastic sheets. High grade products should have superior impact strength and be suitable for various complex environments.

Bending strength: It is crucial for evaluating the rigidity and load-bearing capacity of materials, especially in building applications.

In addition to physical properties, the chemical resistance of plastic hollow universal panels is also a key factor in dividing quality levels. The tolerance of products of different grades to different chemical media (such as acids, bases, salts, etc.) varies. High grade products are generally able to resist the erosion of various chemicals and are suitable for a wider range of applications.

4. Appearance quality

The appearance quality also plays an important role in the market competition of Wantong board. The product should have a smooth surface, without obvious scratches, bubbles, uneven color defects. The appearance quality directly affects the aesthetic appeal and market recognition of the product. Generally, products with better appearance quality have higher quality levels.

5. Dimensional deviation

The dimensional accuracy of a product is also an important criterion for evaluating its quality level. The thickness, length, and width of plastic hollow universal panels must comply with national or industry standards. Excessive dimensional deviation may affect installation and usage effectiveness, therefore, strict control of dimensional accuracy is necessary during the production process.

In practical applications, the quality grade of plastic hollow universal panels is usually classified according to national standards (such as GB, ISO, etc.). At the same time, many production enterprises also obtain specific certifications, such as CE mark, ISO9001 quality management system certification, etc., as the basis for quality assurance.

7. Application Fields

Plastic hollow universal panels of different quality levels are suitable for different engineering projects. For example, high-grade products are usually used for high demand applications such as building exterior walls and partitions, while low-grade products can be used for temporary or low demand projects.

Author:admin