Multi-layer coextrusion high speed cast film machine

Date:2023/3/24 11:23:36 / Read: / Source:This website

Multi-layer coextrusion high speed cast film machine

This production line uses LDPE/LLDPE/MPE as the main raw material, and uses several different grades of resin to extrude through the extruder to produce a self-adhesive single-sided or double-sided adhesive three- or five-layer stretch-wound film.

Production line characteristics:

1. Compact structure and high cost performance; the application of multi-layer coextrusion technology, fully automatic paper tube, roll change, unwinding system, ensuring stable production with high productivity and high line speed and high quality product appearance and performance.

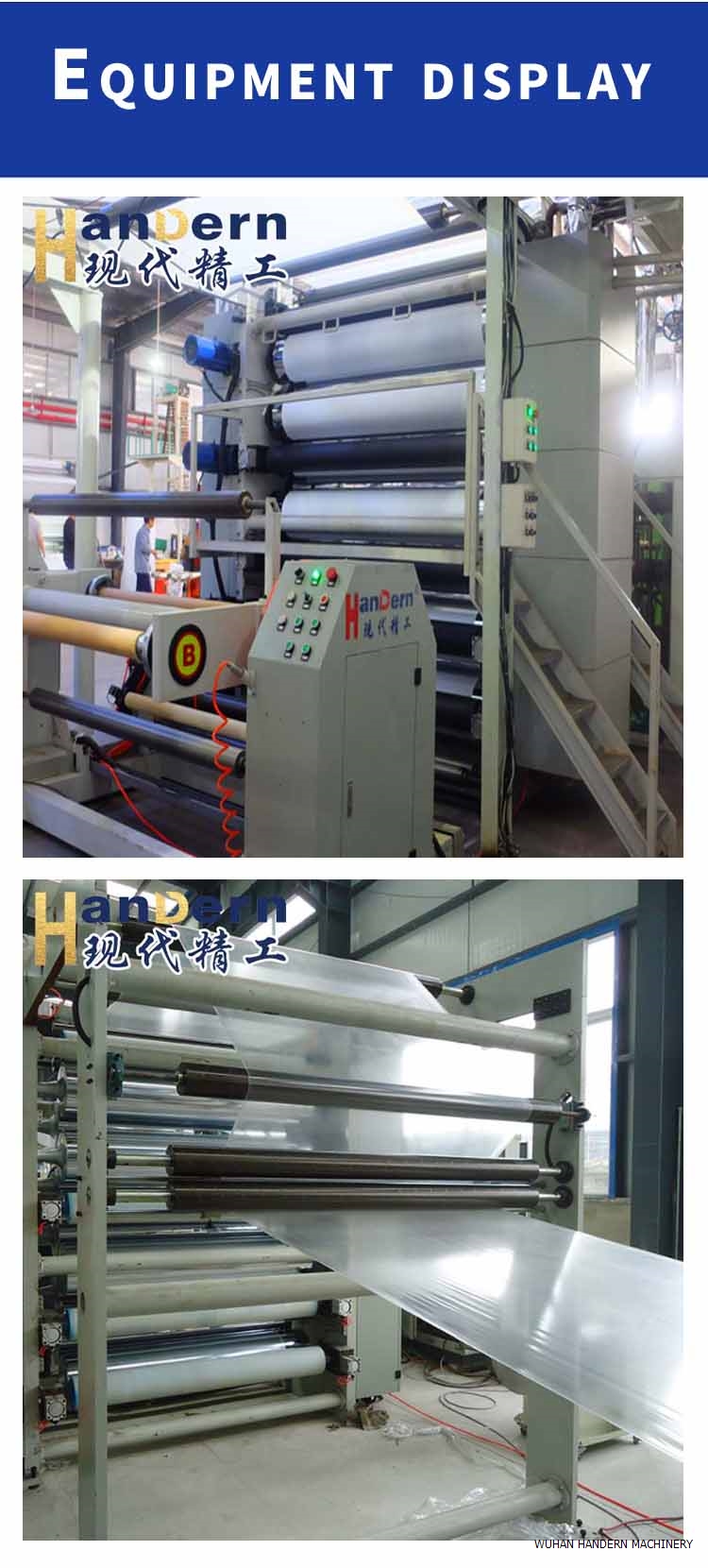

2. The production line is mainly composed of extrusion, casting, traction, lifting, walking, thickness measurement, swinging, trimming, winding, changing, unwinding, paper-carrying, online edge material recycling, electronic control system and other components. .

3. High plasticized alloy screw design and crystal point treatment structure to ensure material plasticization and extrusion stability. The barrel is heated by a ceramic air-cooled heater, which has good heat transfer and heat dissipation performance, and the noise is very low.

4. The cooling roller adopts a large-diameter special flow passage cooling structure to ensure good cooling effect and uniform roll surface temperature in high-speed production.

5. Adopting the latest four-axis winding system, the whole operation time of the reeling is short, the cutting operation can be cut off instantaneously, and the automatic film-free device is adopted, which reduces the waste caused by the traditional reeling and saves the cost.

6. After setting the temperature, only use the lifting speed, automatically calculate according to the setting parameters, the speed changes, the film thickness does not change, and it can also run separately.

7. Casting, pulling and winding are all driven by servo motor to better ensure the synchronization and stability of each part at high speed.

8. The whole machine adopts PLC control and human-machine interface touch screen operation, which can set parameters arbitrarily, and has functions such as automatic calculation, memory, detection and alarm. Support network remote detection, which provides more comprehensive maintenance for the system.

9. Electrical control components are all well-known brands at home and abroad, the production line runs smoothly and reliably, and better guarantees the quality of equipment.

Features:

1. Higher tensile strength, puncture resistance and impact resistance;

2. Good retraction memory and self-adhesiveness, which can make the goods tightly wrapped into a whole and protect the transported articles;

3. Excellent transparency and extensibility, making the packaged items beautiful, economical and practical.

Main use of the product:

It is widely used in packaging materials such as building materials, automobile and motorcycle parts, cylinder film, tube paper, hardware accessories, and bulk pallets for bulk goods. It is a good substitute for heat shrinkable packaging film.

Main technical parameters:

- Model: XD-LYCR-C70/120/80-1000; XD-LYCR-C90/135/100-1500; XD-LYCR-C90/150/110-2000

- Screw length to diameter ratio: 33:1 (L/D)

- Finished product width: 1000mm (500 × 2rolls); 1500mm (500 × 3rolls); 2000mm (500 × 4rolls);

- Finished product thickness: 0.01-0.03 mm;

- Film structure: A/B/C or A/B/A/B/C

- Line speed: 380m/min;

- Total power: 340kw; 450kw; 560kw;

- Power source: 380/3/4/50 (Volt/Ph/Line/Hz)

Author:admin