twin-screw extruders in pc corrugated plastic hollow sheet machine

Date:2016/1/29 11:33:32 / Read: / Source:This website

What are the characteristics of twin-screw extruders in pc corrugated plastic hollow sheet machine?

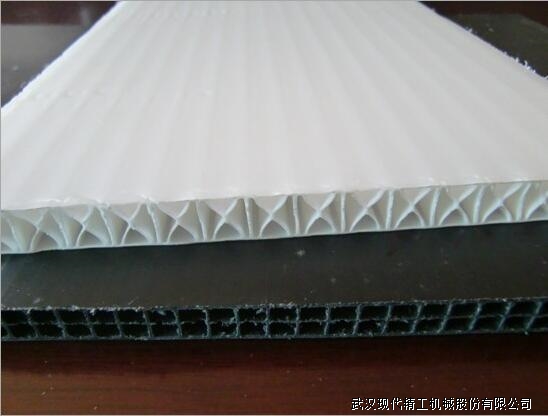

Pc corrugated plastic hollow sheet machine is a new type of plastic board that can be reused. It is currently widely used in construction, packaging, advertising and other fields. However, today I will not talk about the board, but will introduce the equipment used to produce this type of board - the hollow grid board production line.

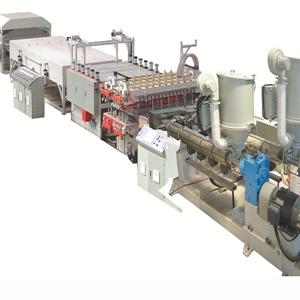

The composition structure of the pc corrugated plastic hollow sheet line includes an extruder, a mold, a vacuum shaping table, a cooling system, a traction system, a heat treatment drying channel, a shearing machine, etc. One of the most core components is its extruder. Currently, there are single screw extruders and twin-screw extruders on the market, among which twin-screw extruders are highly favored by customers.

The working principle of a twin screw extruder is similar to that of a traditional twin screw extruder. However, it uses a special die head that allows two different colored plastic materials to be extruded simultaneously. In the die head, two extrusion outlets are interlocked with each other, and plastic materials of different colors are extruded from different extrusion outlets, ultimately forming a hollow grid plate.

In the production process, it is necessary to control the ratio and flow rate of two plastic materials. This needs to be achieved by controlling the speed, temperature, and pressure of the twin-screw extruder. At the same time, it is necessary to equip a professional control system that can monitor and adjust the production process in real time, ensuring product quality and production efficiency.

In addition, the plastic hollow grid board production line also has some other advantages. Firstly, it can significantly reduce production costs because the formula of hollow grid board is relatively flexible, and different ratios can be made according to customer needs, while the produced board still has good compression resistance and durability. Secondly, it can reduce environmental pollution because hollow grid panels can be recycled and reused.

The other components of the plastic hollow grid board production line are equally important, and every step cannot go wrong. However, the extruder is the extrusion of the entire production line. If good raw materials cannot be extruded, then it is not enough to produce good finished products in the future.

Twin-screw extruders are commonly used in these types of machines due to their several advantages over single-screw extruders:

twin-screw extruders in pc corrugated plastic hollow sheet machine line

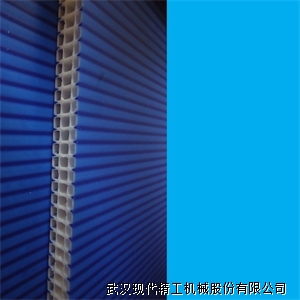

Our thickened hollow board production line can produce hollow boards with a thickness of 12-20mm. The length, width, color and basis weight can be customized according to customer requirements. Made of new materials, the hardness is good, the surface is smooth and clean, and it is mainly suitable for the building use board, the partition plate with high load bearing requirements, and the heavy duty turnover box.,etc.

00#Thickened hollow board machin

Author:admin