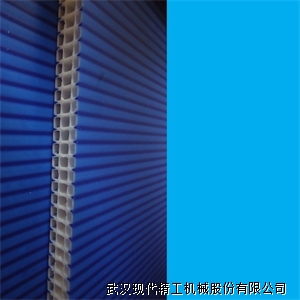

co-extrusion sheet making machine

Date:2019/3/19 10:45:32 / Read: / Source:This website

Co-extrusion sheet making machines are used to produce multi-layer polymer sheets or films. These machines have two or more extruders that feed different molten polymer materials into a single die. The polymers are then co-extruded through the die and cooled to form a cohesive multi-layer sheet or film.

Applications of co-extrusion sheet making machine

Plastic hollow board, Plastic fluted sheet, Antistatic plastic corrugated sheet, Plastic hollow sheet for electrics bottom protection, PP hollow sheet clapboard, PE hollow board, Plastic advertising display board, Plastic corrugated sheet for bottles layer pallet, PP coroplast sheet, PP carton plast sheet, PP correx sheet, Edge sealing PP corrugated board, PP turnover container box for packaging, PP corrugated packaging box for vegetable export, PP turnover packaging box for asparagus, PP collapsible packaging box for grape, Plastic fire-retarding packaging box, PP packaging box for pesticide, PP hollow sheet backboard for refrigerator and other PP hollow sheet products.

The company's leading product is "complete sets of hollow profile sheet production line series and molds", according to the difference of thickness, width, structure, shape, plastic materials used in the production has different classifications:

1. According to product width: we have 1400mm, 1800mm, 2300mm, 2400mm,2600mm, 2800 units

2. According to product thickness: we have 2-6mm, 6-12mm, 12-18mm unit

3. According to the product structure: we have double wall sheet, three wall sheet, four wall sheet,

4. According to product shape: we have ordinary type I, S type, V type, X type, 米 type, etc.

5. Use plastic raw materials according to products: we have PP, PE, PC

In addition, there are also a series of products such as thin sheet and hollow file films for greenhouses,etc series products.

Main Parts of co-extrusion sheet making machine

1.Single screw extruder2.Hydraulic pressure quick change filter net

3.Die

4.Calibration table

5.First haul-off unit

6. Oven

7.Cooling station

8.Second haul-off unit

9.Cutting unit

10.Automatic control cabinet

11.Stack table

12.Screw loader

Key Parts of co-extrusion sheet making machine

1. Extruder

Specially designed extruder screw and advanced temperature control

system retain the plastic properties of the polycarbonate resin while ensuring

extrusion efficiency. High energy efficiency is a major benefit of this PC

sheet extruder. The extruder motor consumes 20% less power than an equivalent

motor made by our competitors.

2. Extrusion Die

High quality alloy extrusion die lip and choker bar provides

uniform pressure drop from die inlet to die lip. Precisely machined die assures

good quality of finished extruded sheet.

3. Vacuum Calibration Table

The thermal convection system of the calibration table features an

intersection arrangement which ensures the hot PC resin flow is effectively

cooled and the final extrudate achieves the desired shape and accurate

dimensions. As far as the shape forming process is concerned, our multiwall

sheet extrusion machinery allows rapid shape formation through sizing and

cooling without the need of cold water. It helps save energy and improves

efficiency.

4. Dry Vacuum Calibrator

The vacuum calibrator consists of 2 independent sub-systems, which

are equipped with many close-loop vacuum channels.

5. Electrical Control System

Programmable logic control ensures precise extrusion process

parameters and optimized operation features.

Benefits of co-extrusion sheet making machine

1. Required high production efficiency

2. Production flexibility( controllable sheet thickness and width, for example, you can produce 2-6mm thick sheet with the same mould or machine)

3. Reliability and stability

4.Excellent Adaptability to different raw material and reach over 30% production cost reduction.

5. Size and shape diversity of finished products

Author:admin