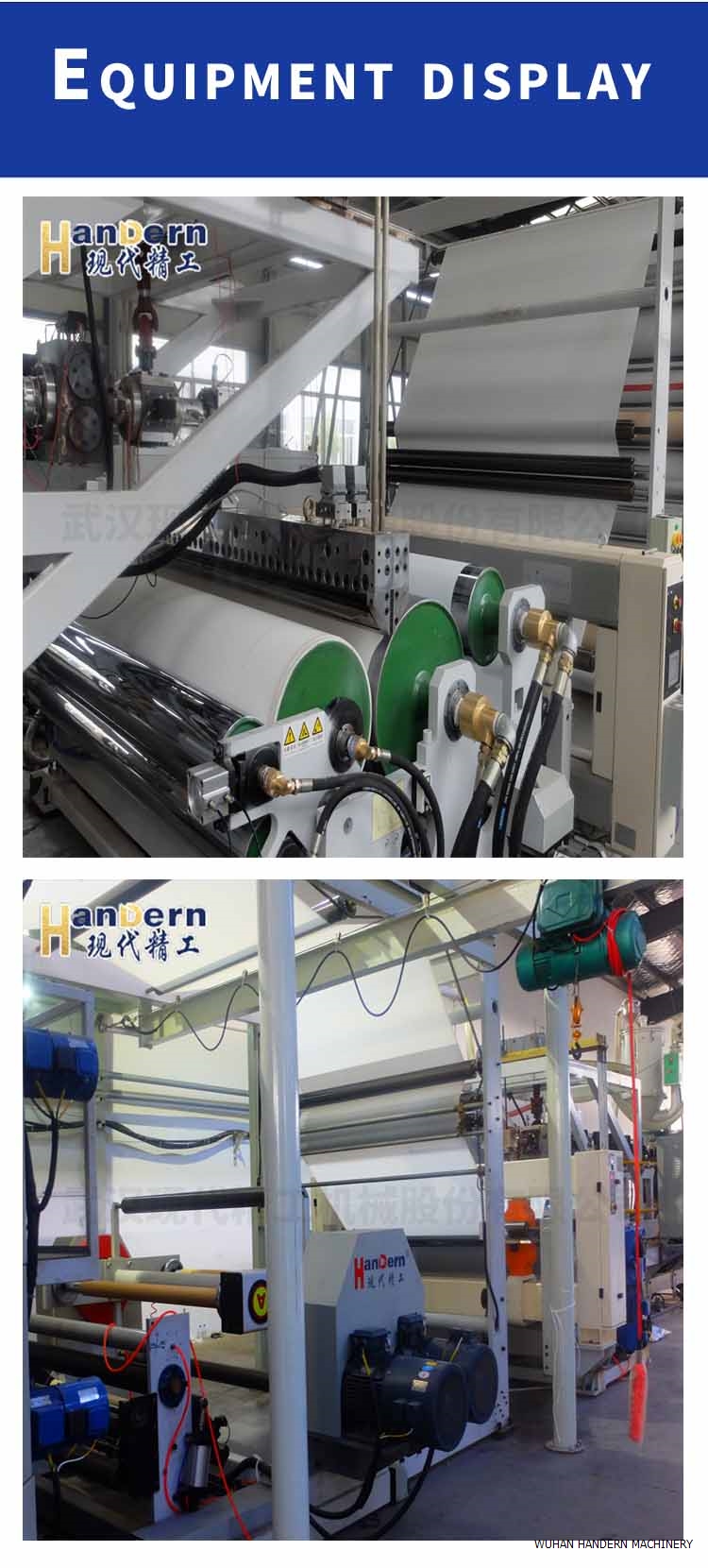

PCTFE film machine

Date:2019/3/20 11:06:06 / Read: / Source:This website

PCTFE film machine mMain functions:

Chlorotrifluoroethylene polymer. Abbreviation PCTFE. Structure is melting temperature 213 ℃, excellent chemical stability, insulation and weather resistance, long-term use in -196 ~ 125 ℃, mechanical strength and hardness better than polytetrafluoroethylene, has good transparency and low ventilation rates when use PCTFE to produce film. PCTFE is a crystalline polymer, the melting point is 425F, and density is 2.13g/cc (g / cc).

PCTFE is a tri-fluorometry radical polymerization of vinyl chloride with a product of a main repeating CF (cl)-CF element linear backbone.

PCTFE is a crystalline polymer, the melting point is 425F, and density is 2.13g/cc (g / cc).

PCTFE inert to most active chemicals at room temperature , and can be dissolved in a solvent few in 212T above, some of the solvent may also be swollen, especially for chlorinated solvents . PCTFE has excellent gas barrier ability, the water vapor permeability of the film product is the lowest in all transparent plastic film. The electrical properties are similar with other perfluorinated polymers , but the dielectric constant (2.3-2. 7 and loss factor is a little bit higher , especially at high frequencies. PCTFE can be made thick (1/8 in.) optically transparent parts.

Process and applications:

Although the PCTFE available melting processing, but due to the high melt viscosity, a trend of degradation leads to bad performance of processed products,the processing is difficult.

PCTFE resin can made for extrusion and molding pellets . Film thickness is 0.001-0.010 inches, also can be made for rods and tubes. Polytrifluorochloroethylene (referred to as F3) resin spray method, is corrosion resistant technology for chemical equipments. It consists of polychlorotrifluoroethylene resin, phenol resin, graphite powder mixed as a surface adhesive for polychlorotrifluoroethylene plastic and metal equipment.Before coating the F3 surface layer, first spray an adhesive intermediate layer on the metal substrate surface. This method is simple, easy to operate, regardless of equipment shape, size limit, its sprayed equipment with widely use medium and high strength, can be widely used in petroleum, chemical, pharmaceutical, pesticide and other chemical industries corrosive.

Mainly used for corrosion-resistant parts in chemical equipment, such as linings and coatings for pipes, valves, valve seats, high pressure seal packing, gears, bearings, diaphragms, gaskets, reactors, tanks, fans, centrifuges and others ;and moisture-proof, anti-sticking coating layer for electronic equipment high-frequency insulation, high-frequency cables, coil insulation, etc.;

Author:admin