What are the characteristics of twin-screw extruders

DATE:2024/10/9 11:37:08 / READ: / SOURCE:This station

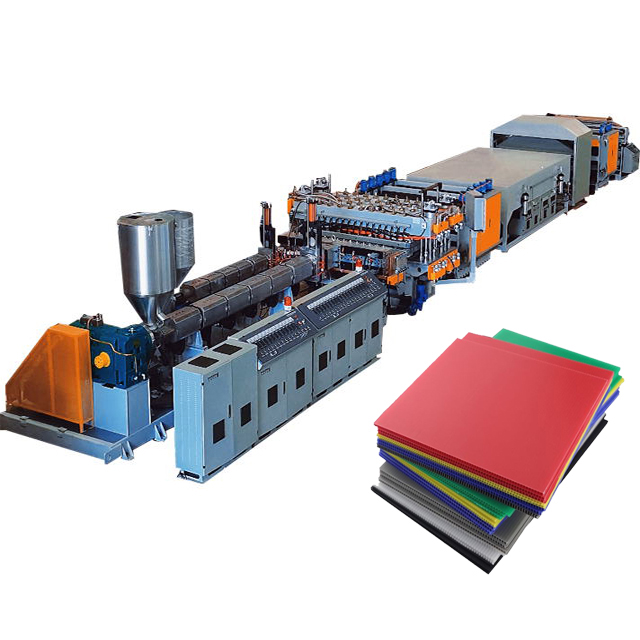

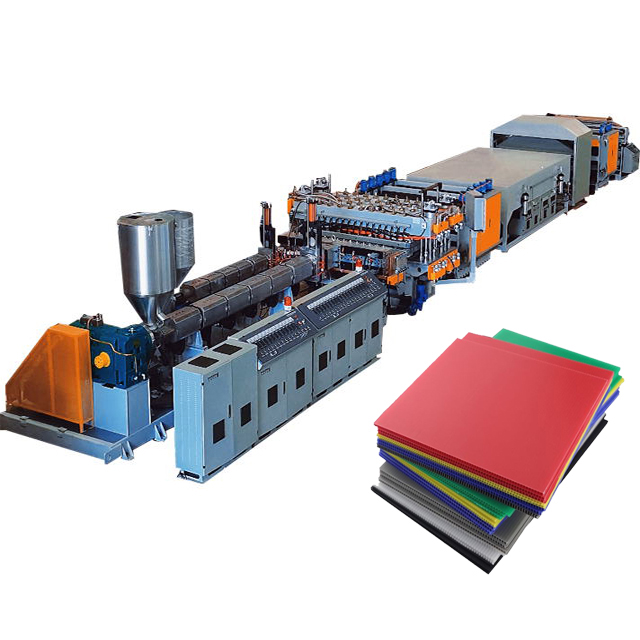

Twin screw extruder is an important equipment in the plastic processing industry, widely used in fields such as plastics, rubber, food, and chemical engineering. Its core components are two parallel screws that interact through rotation, heating, mixing, plasticizing, and extruding raw materials such as plastic particles or powders.

1. Structure and working principle

1. Structure and working principle

The structure of a twin-screw extruder mainly includes a screw, a barrel, a drive system, and a mold. Screws are usually composed of multiple segments, each with different functions such as conveying, mixing, or plasticizing. Through different designs, screws can achieve effective material transfer and heating.

The working principle of a twin-screw extruder is to drive the screw to rotate through an electric motor, and the raw material is heated and plasticized inside the heat engine cylinder. The rotation of the screw pushes the material forward, while producing shear and mixing effects, allowing the raw materials to be uniformly plasticized in a hot environment. Finally, after extrusion through the mold, the desired product is formed.

2. Main advantages

2. Main advantages

Efficient mixing: The interaction between twin-screw can achieve efficient material mixing, suitable for handling formulations with multiple components, especially the dispersibility of additives and fillers.

Adjustable: The twin-screw extruder has good process flexibility and can adjust parameters such as screw speed, temperature, and pressure according to different production needs.

Good plasticizing performance: Its unique design enables twin-screw to complete plasticization in a shorter time, especially for high viscosity or difficult to process materials, the effect is more significant.

Wide applicability: The twin-screw extruder can be used for processing various plastics, rubber, and composite materials, and is suitable for the production of various products such as films, sheets, pipes, and particles.

3. Application Fields

3. Application Fields

Plastic processing: used for producing various plastic products such as PE, PP, PVC, etc., suitable for multi-layer co extrusion production.

Material modification: It can modify plastics, such as strengthening, toughening, filling, etc., to improve material properties.

Food processing: can be used for extrusion processing of starch, grains, and other food raw materials, suitable for making puffed foods and feed.

Chemical industry: used for producing coatings, adhesives, and other chemical products, achieving uniform mixing and molding of materials.

The structure of a twin-screw extruder mainly includes a screw, a barrel, a drive system, and a mold. Screws are usually composed of multiple segments, each with different functions such as conveying, mixing, or plasticizing. Through different designs, screws can achieve effective material transfer and heating.

The working principle of a twin-screw extruder is to drive the screw to rotate through an electric motor, and the raw material is heated and plasticized inside the heat engine cylinder. The rotation of the screw pushes the material forward, while producing shear and mixing effects, allowing the raw materials to be uniformly plasticized in a hot environment. Finally, after extrusion through the mold, the desired product is formed.

Efficient mixing: The interaction between twin-screw can achieve efficient material mixing, suitable for handling formulations with multiple components, especially the dispersibility of additives and fillers.

Adjustable: The twin-screw extruder has good process flexibility and can adjust parameters such as screw speed, temperature, and pressure according to different production needs.

Good plasticizing performance: Its unique design enables twin-screw to complete plasticization in a shorter time, especially for high viscosity or difficult to process materials, the effect is more significant.

Wide applicability: The twin-screw extruder can be used for processing various plastics, rubber, and composite materials, and is suitable for the production of various products such as films, sheets, pipes, and particles.

Plastic processing: used for producing various plastic products such as PE, PP, PVC, etc., suitable for multi-layer co extrusion production.

Material modification: It can modify plastics, such as strengthening, toughening, filling, etc., to improve material properties.

Food processing: can be used for extrusion processing of starch, grains, and other food raw materials, suitable for making puffed foods and feed.

Chemical industry: used for producing coatings, adhesives, and other chemical products, achieving uniform mixing and molding of materials.

Author:admin