What is PEM proton exchange membrane

DATE:2024/6/28 15:26:48 / READ: / SOURCE:This station

PEM proton exchange membrane is a polymer material with excellent proton conductivity and chemical stability, and it is the core component of fuel cells. In fuel cells, PEM proton exchange membranes act as ion transport channels, converting the chemical energy of hydrogen and oxygen into electrical energy. During this process, no harmful substances to the environment are produced. Therefore, PEM fuel cells have excellent environmental protection and pollution-free advantages. Currently, this type of battery is widely used in fields such as automobiles, ships, and drones.

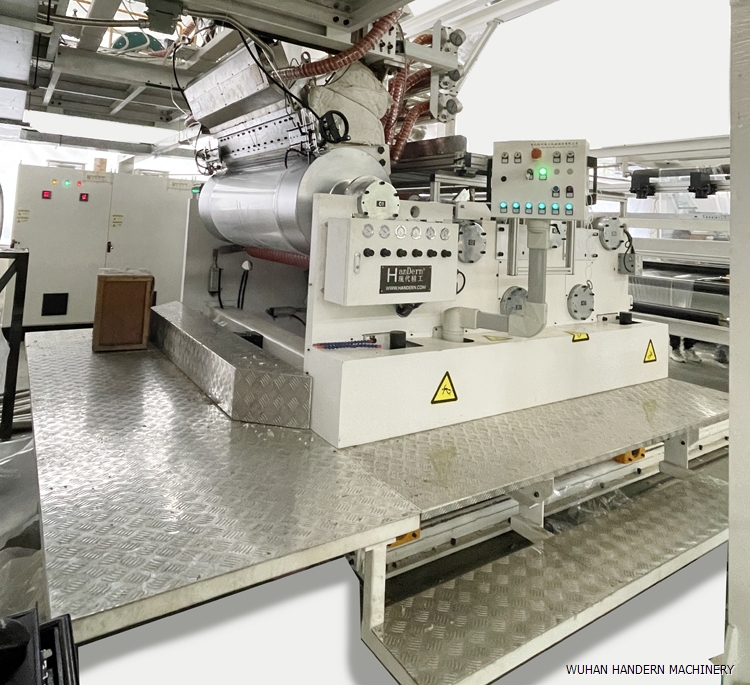

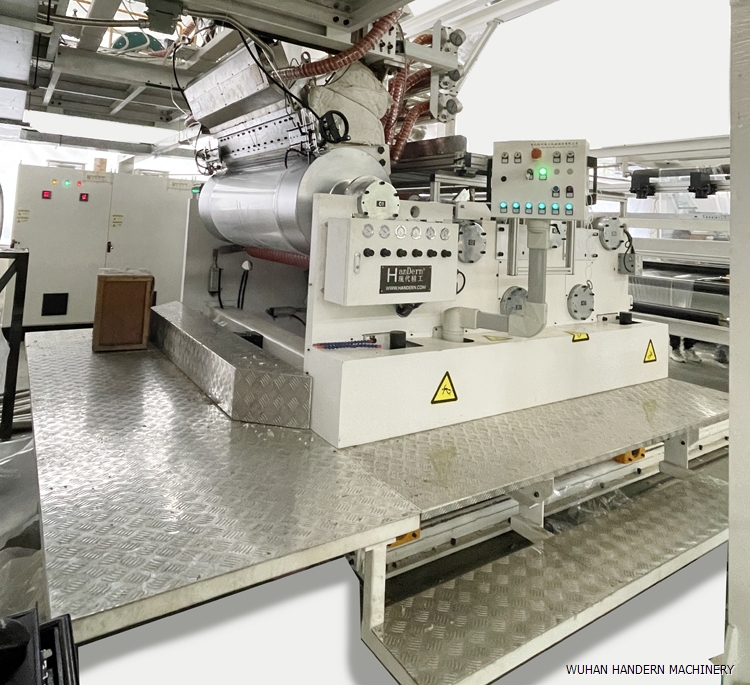

Wuhan Modern Precision Machinery Co., Ltd. has been committed to the development and research of the new energy industry for many years. Our lithium battery separator production line has a considerable proportion in the domestic market, and many large listed companies are our customers. PEM proton exchange membranes are another key research object of ours, and this project has achieved significant breakthroughs.

It is difficult to successfully produce PEM proton exchange membranes. Firstly, its production cost is high because it requires the use of high-purity raw materials such as polytetrafluoroethylene, and the production process requires strict control of conditions such as temperature and humidity; Secondly, the production of PEM proton exchange membranes requires multiple complex process steps, including solution preparation, film casting, drying, heat treatment, etc. Each process requires precise control, and any problems that arise will affect membrane quality; Finally, high requirements are placed on the performance of the membrane. PEM proton exchange membranes need to have good stability and durability in fuel cells, and can maintain good performance in long-term high temperature and high pressure environments. Therefore, high production process requirements are required.

It is difficult to successfully produce PEM proton exchange membranes. Firstly, its production cost is high because it requires the use of high-purity raw materials such as polytetrafluoroethylene, and the production process requires strict control of conditions such as temperature and humidity; Secondly, the production of PEM proton exchange membranes requires multiple complex process steps, including solution preparation, film casting, drying, heat treatment, etc. Each process requires precise control, and any problems that arise will affect membrane quality; Finally, high requirements are placed on the performance of the membrane. PEM proton exchange membranes need to have good stability and durability in fuel cells, and can maintain good performance in long-term high temperature and high pressure environments. Therefore, high production process requirements are required.

How to produce high-quality PEM proton exchange membranes? To make high-performance PEM membranes, we need to take the selection of raw materials seriously, such as polymer electrolyte membranes, electrodes, and catalysts. These materials play a crucial role in determining the performance and durability of PEM.

Once the raw materials are ready, the next step is the preparation of the membrane. This involves casting a thin film of polymer electrolyte solution onto the substrate, and then removing any excess solvent through a drying process. The thickness and uniformity of the film are key factors that need to be carefully controlled in this step.

After the membrane preparation is completed, the next step is the "ion exchange" process. This step involves immersing the membrane in a solution containing protons or other cations, which replace the ions present in the membrane. This ion exchange process helps to improve the proton conductivity of the membrane, which is crucial for its performance in fuel cell applications.

After ion exchange, the membrane typically undergoes a series of post-treatment steps. These steps can include hot pressing, annealing, and chemical treatment to further improve the mechanical and thermal stability of the film. The purpose of these post-processing steps is to optimize the performance of the membrane and ensure its long-term durability.

After ion exchange, the membrane typically undergoes a series of post-treatment steps. These steps can include hot pressing, annealing, and chemical treatment to further improve the mechanical and thermal stability of the film. The purpose of these post-processing steps is to optimize the performance of the membrane and ensure its long-term durability.

After the membrane is ready, assemble it into a proton exchange membrane fuel cell (PEMFC) stack. Stacking consists of multiple layers of film, electrodes, and gas diffusion layers. The assembly process requires precise alignment and sealing to prevent any leaks and ensure efficient proton transfer within the fuel cell.

After assembly, the PEMFC stack will undergo strict testing and quality control procedures. These tests evaluate the performance, durability, and reliability of stacking under various working conditions. Any defects or issues discovered during the testing process will be resolved and necessary adjustments or improvements will be made to meet the required specifications.

It can be seen that the production process of PEM proton exchange membranes is very complex, including a series of steps such as raw material selection, membrane preparation, ion exchange, post-treatment, assembly, and testing. Each step plays a crucial role in determining the quality and performance of the final product. Wuhan Modern Precision Machinery Co., Ltd. has entered the final stage of research and development for the PEM proton exchange membrane production line. We believe that soon everyone will see our production line enter the market and make a contribution to the development of the new energy industry.

It can be seen that the production process of PEM proton exchange membranes is very complex, including a series of steps such as raw material selection, membrane preparation, ion exchange, post-treatment, assembly, and testing. Each step plays a crucial role in determining the quality and performance of the final product. Wuhan Modern Precision Machinery Co., Ltd. has entered the final stage of research and development for the PEM proton exchange membrane production line. We believe that soon everyone will see our production line enter the market and make a contribution to the development of the new energy industry.

Wuhan Modern Precision Machinery Co., Ltd. has been committed to the development and research of the new energy industry for many years. Our lithium battery separator production line has a considerable proportion in the domestic market, and many large listed companies are our customers. PEM proton exchange membranes are another key research object of ours, and this project has achieved significant breakthroughs.

How to produce high-quality PEM proton exchange membranes? To make high-performance PEM membranes, we need to take the selection of raw materials seriously, such as polymer electrolyte membranes, electrodes, and catalysts. These materials play a crucial role in determining the performance and durability of PEM.

Once the raw materials are ready, the next step is the preparation of the membrane. This involves casting a thin film of polymer electrolyte solution onto the substrate, and then removing any excess solvent through a drying process. The thickness and uniformity of the film are key factors that need to be carefully controlled in this step.

After the membrane preparation is completed, the next step is the "ion exchange" process. This step involves immersing the membrane in a solution containing protons or other cations, which replace the ions present in the membrane. This ion exchange process helps to improve the proton conductivity of the membrane, which is crucial for its performance in fuel cell applications.

After the membrane is ready, assemble it into a proton exchange membrane fuel cell (PEMFC) stack. Stacking consists of multiple layers of film, electrodes, and gas diffusion layers. The assembly process requires precise alignment and sealing to prevent any leaks and ensure efficient proton transfer within the fuel cell.

After assembly, the PEMFC stack will undergo strict testing and quality control procedures. These tests evaluate the performance, durability, and reliability of stacking under various working conditions. Any defects or issues discovered during the testing process will be resolved and necessary adjustments or improvements will be made to meet the required specifications.

Author:admin