What is the structure of the vacuum extrusion molding fiber cement board production line

DATE:2024/6/27 14:27:49 / READ: / SOURCE:This station

The vacuum extrusion molding fiber cement board production line consists of a raw material storage, transportation, and metering system, a stirring and mixing system, an extrusion molding system, a microwave curing system, a grabbing and stacking system, and a storage and transportation system.

Raw material storage, transportation, and metering system: It stores cement, sand, lightweight aggregates, etc., and during the pre operation period of the mixing equipment, a certain amount of cement, sand, and fly ash are transported to the high-speed mixer through the metering device.

Mixing and mixing system: It consists of a high-speed mixing mixer and a screw extrusion kneading machine. The high-speed mixing mixer relies on the planetary axis installed in the mixing drum to drive the blades to continuously rotate, and to perform composite movements such as forced compression and flipping of the material, thereby achieving forced mixing and uniform mixing of the material. Cement, fly ash, and fibers are mixed evenly by a high-speed mixer and enter the kneading machine through the discharge port. After thorough mixing in the kneading machine, they are extruded by the bottom screw and transported to the extrusion molding system through a belt conveyor.

Mixing and mixing system: It consists of a high-speed mixing mixer and a screw extrusion kneading machine. The high-speed mixing mixer relies on the planetary axis installed in the mixing drum to drive the blades to continuously rotate, and to perform composite movements such as forced compression and flipping of the material, thereby achieving forced mixing and uniform mixing of the material. Cement, fly ash, and fibers are mixed evenly by a high-speed mixer and enter the kneading machine through the discharge port. After thorough mixing in the kneading machine, they are extruded by the bottom screw and transported to the extrusion molding system through a belt conveyor.

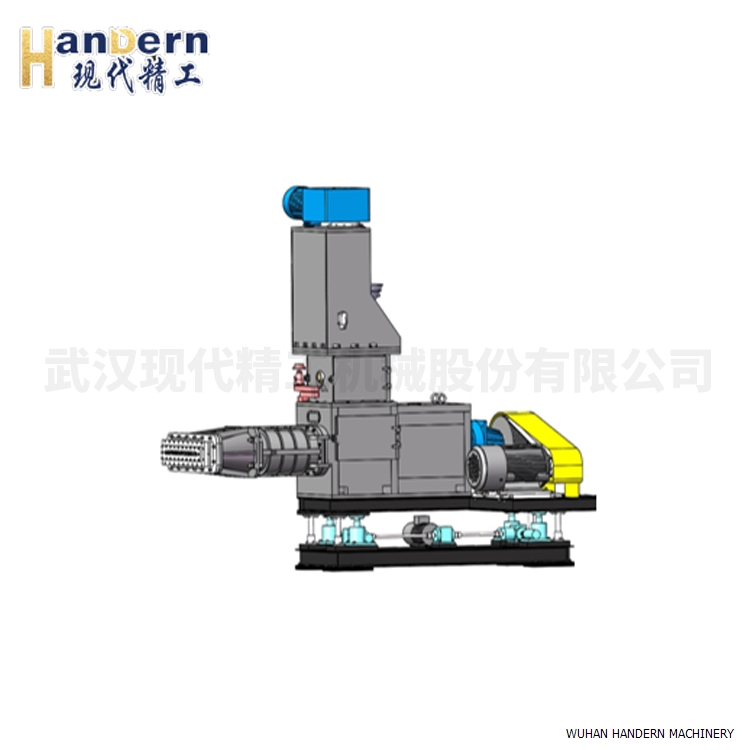

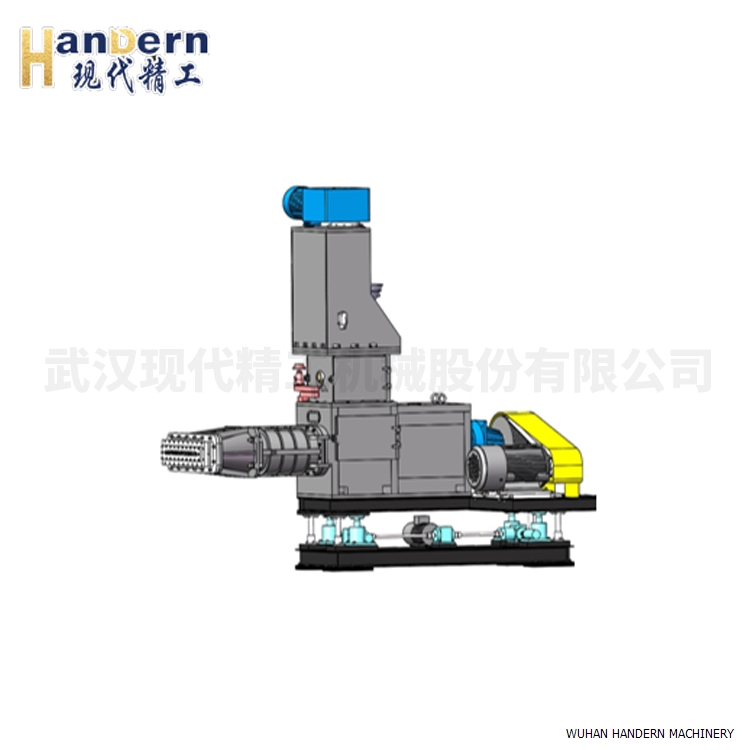

Vacuum extrusion molding system: It consists of a vertical double helix vacuum extruder and a molding mold. After mixing materials such as cement, lightweight aggregates (fly ash, coal gangue, perlite, etc.), sand, plastic fibers, etc., it is vacuum degassed in the vacuum extruder and extruded into slabs with different cross-sectional shapes through the mold mouth under the high extrusion pressure and high shear force of the screw cutter.

Vacuum extrusion molding system: It consists of a vertical double helix vacuum extruder and a molding mold. After mixing materials such as cement, lightweight aggregates (fly ash, coal gangue, perlite, etc.), sand, plastic fibers, etc., it is vacuum degassed in the vacuum extruder and extruded into slabs with different cross-sectional shapes through the mold mouth under the high extrusion pressure and high shear force of the screw cutter.

Microwave maintenance system: Microwave is an electromagnetic wave with a frequency ranging from 300MHz to 300GMHz, whose direction and magnitude vary periodically over time. The process of microwave heating is the direct interaction between microwave and materials, which converts ultra-high frequency electromagnetic waves into thermal energy. The plate preform extruded by a vacuum extruder is fed into a microwave curing oven through a transmission belt, which quickly dries and hardens under the action of the microwave.

Microwave maintenance system: Microwave is an electromagnetic wave with a frequency ranging from 300MHz to 300GMHz, whose direction and magnitude vary periodically over time. The process of microwave heating is the direct interaction between microwave and materials, which converts ultra-high frequency electromagnetic waves into thermal energy. The plate preform extruded by a vacuum extruder is fed into a microwave curing oven through a transmission belt, which quickly dries and hardens under the action of the microwave.

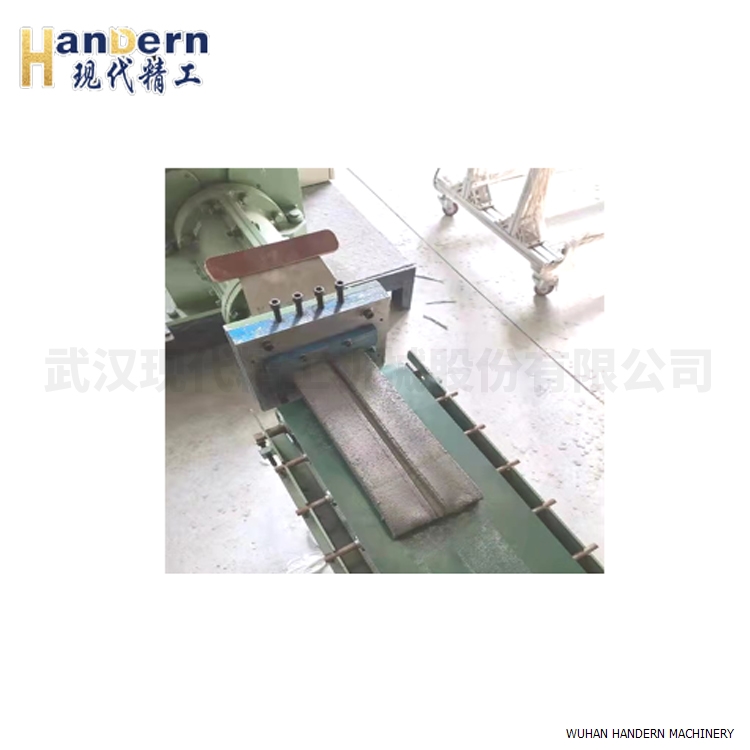

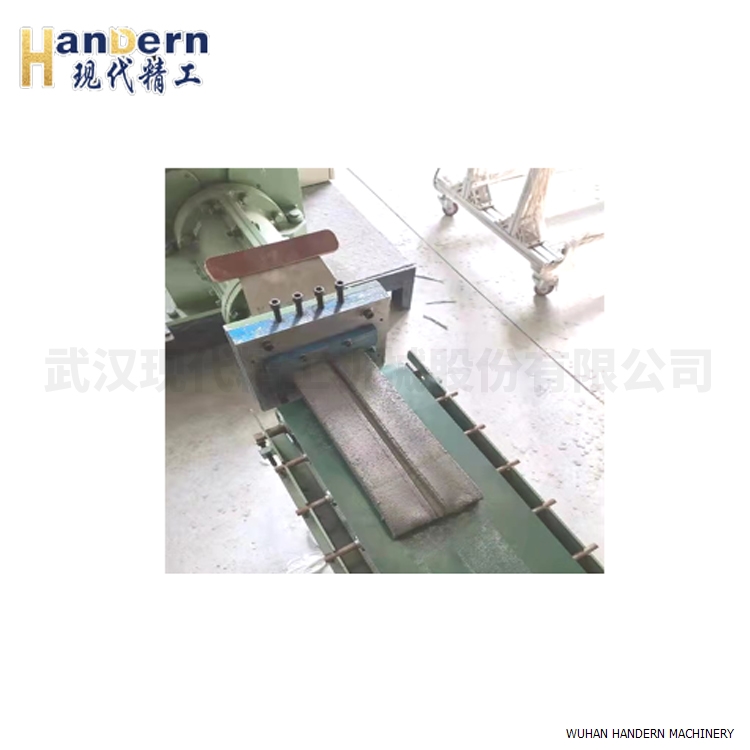

Synchronous cutting system: It is composed of a synchronous cutting machine and related control systems. It cuts the wet blank sheet extruded by the extruder into a certain length of wet blank sheet according to the required length. During the cutting process, the saw blade moves synchronously along the direction of sheet transportation at the speed of sheet transportation, ensuring the flatness of the sheet end face.

Synchronous cutting system: It is composed of a synchronous cutting machine and related control systems. It cuts the wet blank sheet extruded by the extruder into a certain length of wet blank sheet according to the required length. During the cutting process, the saw blade moves synchronously along the direction of sheet transportation at the speed of sheet transportation, ensuring the flatness of the sheet end face.

Grasping and Stacking System: After curing and hardening, the fiber cement board is grabbed from the conveyor roller through a gantry grabbing device and stacked in a designated area.

Grasping and Stacking System: After curing and hardening, the fiber cement board is grabbed from the conveyor roller through a gantry grabbing device and stacked in a designated area.

Storage and transportation system: The storage and transportation system includes large storage shelves for stacking finished products, intelligent transportation trailers for shipment, and loading and stacking devices.

Storage and transportation system: The storage and transportation system includes large storage shelves for stacking finished products, intelligent transportation trailers for shipment, and loading and stacking devices.

Through the above components, we have formed a complete vacuum extrusion molding fiber cement board production line. This production line can mix cement (ordinary Portland cement), lightweight aggregates (industrial solid waste such as fly ash, coal gangue, phosphogypsum), coarse sand (construction solid waste - concrete blocks, bricks, recycled aggregates made through crushing and screening processes, tailings sand, etc.), fine sand (natural sand, machine made sand, etc.), plastic fibers and other materials. After mixing, the production line can vacuum exhaust through an extruder, and under the action of high-pressure extrusion force, a series of boards with different cross-sectional shapes are extruded at the mold mouth. At present, this fiber cement board can be used for interior and exterior wall panels, floors, ceilings, etc. In addition, this board can also be used for outdoor curtain walls, indoor partitions, indoor background walls, steps, landscape walkways, walls, sound barriers (high-speed rail, highway), etc.

Raw material storage, transportation, and metering system: It stores cement, sand, lightweight aggregates, etc., and during the pre operation period of the mixing equipment, a certain amount of cement, sand, and fly ash are transported to the high-speed mixer through the metering device.

Through the above components, we have formed a complete vacuum extrusion molding fiber cement board production line. This production line can mix cement (ordinary Portland cement), lightweight aggregates (industrial solid waste such as fly ash, coal gangue, phosphogypsum), coarse sand (construction solid waste - concrete blocks, bricks, recycled aggregates made through crushing and screening processes, tailings sand, etc.), fine sand (natural sand, machine made sand, etc.), plastic fibers and other materials. After mixing, the production line can vacuum exhaust through an extruder, and under the action of high-pressure extrusion force, a series of boards with different cross-sectional shapes are extruded at the mold mouth. At present, this fiber cement board can be used for interior and exterior wall panels, floors, ceilings, etc. In addition, this board can also be used for outdoor curtain walls, indoor partitions, indoor background walls, steps, landscape walkways, walls, sound barriers (high-speed rail, highway), etc.

Author:admin