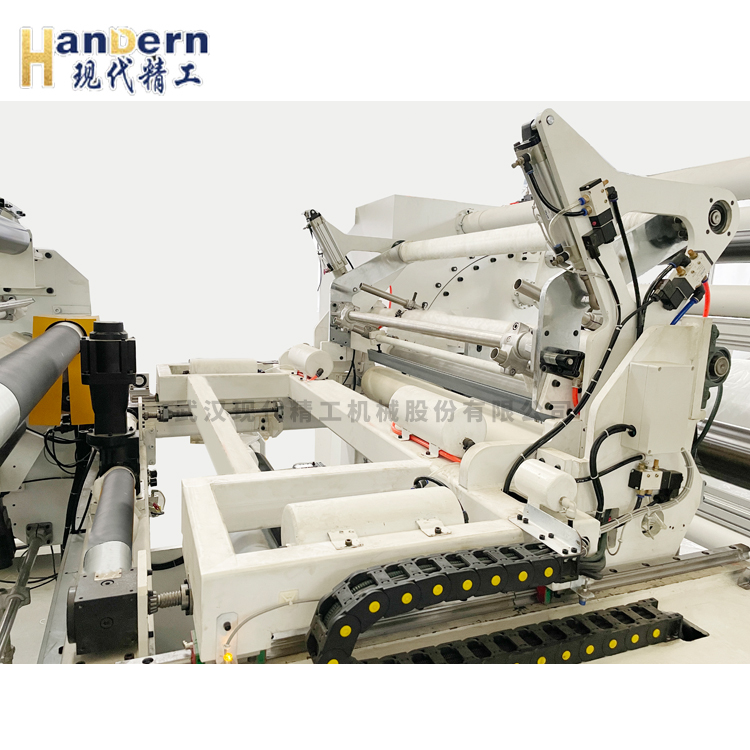

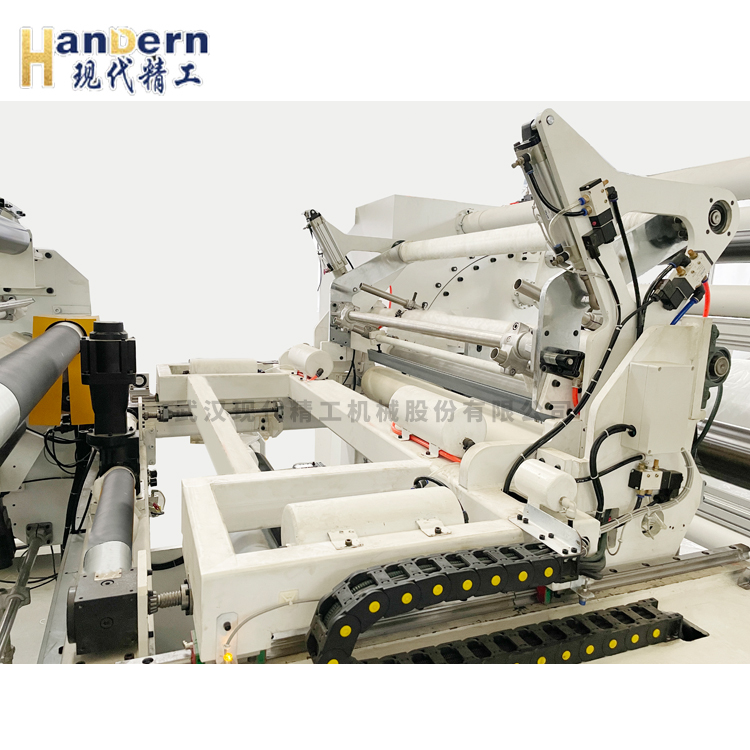

Explanation of the working principle of the casting and stretching machine

DATE:2023/7/6 14:35:56 / READ: / SOURCE:This station

The tape drawing machine is a device used for preparing plastic films. It extrudes molten plastic into a thin film and then makes the film thinner, longer, and more uniform during the stretching process.

The specific working principle is as follows:

The specific working principle is as follows:

Feeding: Add plastic particles or granular materials to the feeding port of the machine.

Melting: Inside the machine, plastic particles are melted into a melt by heating and stirring.

Extrusion: The molten plastic melt is extruded through a mold, forming a thin film.

Cooling: The film is rapidly cooled and solidified through cooling rollers or cooling airflow.

Stretch: The cooled film passes through a pair of rollers, one of which rotates faster and the other rotates slower, causing the film to be stretched between the rollers. During the stretching process, the width of the film gradually narrows, the length gradually increases, and the thickness gradually decreases.

Roll up: The stretched film is rolled up onto the reel, forming a longer roll of film.

Throughout the process, it is necessary to control parameters such as feeding speed, temperature, extrusion speed, and stretching speed to ensure that the film has the required thickness, width, and stretching performance.

The film extruded by the casting and stretching machine has the following characteristics:

Uniform thickness: The tape drawing machine uses the stretching process to make the thickness of the film more uniform and reduce thickness changes.

Adjustable length: During the stretching process, the length of the film will increase, and the degree of stretching can be adjusted as needed to obtain films of different lengths.

Adjustable width: During the stretching process, the width of the film gradually narrows, and the stretching speed and width can be adjusted as needed to obtain films of different widths.

Adjustable thickness: By controlling the extrusion and stretching speeds, the thickness of the film can be adjusted to obtain films of different thicknesses.

Smooth surface: During the extrusion and stretching process, the tape drawing machine cools and stretches the film surface to become smooth without obvious textures and defects.

Good plasticity: The extruded film has a more orderly arrangement of molecular chains due to stretching, which has good plasticity and tensile properties. It is suitable for various packaging, covering, and printing applications.

Overall, the film extruded by the tape drawing machine has the characteristics of uniform thickness, adjustable length, width, thickness, smooth surface, and good plasticity, which can meet the needs of different application fields.

Feeding: Add plastic particles or granular materials to the feeding port of the machine.

Melting: Inside the machine, plastic particles are melted into a melt by heating and stirring.

Extrusion: The molten plastic melt is extruded through a mold, forming a thin film.

Cooling: The film is rapidly cooled and solidified through cooling rollers or cooling airflow.

Stretch: The cooled film passes through a pair of rollers, one of which rotates faster and the other rotates slower, causing the film to be stretched between the rollers. During the stretching process, the width of the film gradually narrows, the length gradually increases, and the thickness gradually decreases.

Roll up: The stretched film is rolled up onto the reel, forming a longer roll of film.

Throughout the process, it is necessary to control parameters such as feeding speed, temperature, extrusion speed, and stretching speed to ensure that the film has the required thickness, width, and stretching performance.

The film extruded by the casting and stretching machine has the following characteristics:

Uniform thickness: The tape drawing machine uses the stretching process to make the thickness of the film more uniform and reduce thickness changes.

Adjustable length: During the stretching process, the length of the film will increase, and the degree of stretching can be adjusted as needed to obtain films of different lengths.

Adjustable width: During the stretching process, the width of the film gradually narrows, and the stretching speed and width can be adjusted as needed to obtain films of different widths.

Adjustable thickness: By controlling the extrusion and stretching speeds, the thickness of the film can be adjusted to obtain films of different thicknesses.

Smooth surface: During the extrusion and stretching process, the tape drawing machine cools and stretches the film surface to become smooth without obvious textures and defects.

Good plasticity: The extruded film has a more orderly arrangement of molecular chains due to stretching, which has good plasticity and tensile properties. It is suitable for various packaging, covering, and printing applications.

Overall, the film extruded by the tape drawing machine has the characteristics of uniform thickness, adjustable length, width, thickness, smooth surface, and good plasticity, which can meet the needs of different application fields.

Author:admin