Explanation of knowledge about the motor and gearbox of the casting film production line

DATE:2023/7/4 14:53:38 / READ: / SOURCE:This station

The casting film production line can be equipped with single or double screws according to customer needs. Many customers are not very familiar with the differences between the two. Today, I will briefly introduce the differences between single and double screws. In addition, I will also introduce the motor and gearbox of the casting film production line to everyone. Therefore, this article is full of goods and I hope everyone likes it after reading it.

1、 The difference between single screw and twin screw

1、 The difference between single screw and twin screw

Single screw casting film production line:

The single screw casting film production line uses a separate screw to feed plastic raw materials from the hopper into the screw barrel of the extruder, and the plastic raw materials are heated, melted, and mixed through the rotation of the screw. The single screw casting film production line is suitable for producing some simple film products, such as plastic bags, plastic films, etc.

Twin screw casting film production line:

The twin screw casting film production line adds an auxiliary screw on top of the single screw, and through the synergistic effect of the twin screws, it can better complete the melting, mixing, and extrusion of plastic raw materials. The twin screw casting film production line is suitable for producing complex thin film products, such as multi-layer composite films, functional films, etc.

2、 Introduction to Motors for Casting Film Production Line

The extrusion motor is one of the important components in the casting film production line, mainly used to drive the rotation of the screw. The extrusion motor is usually an AC or DC motor, and its power size is determined based on the scale and demand of the production line. The speed of the extrusion motor can be adjusted through a frequency converter to control the extrusion speed and thickness of the product.

The extrusion motor is one of the important components in the casting film production line, mainly used to drive the rotation of the screw. The extrusion motor is usually an AC or DC motor, and its power size is determined based on the scale and demand of the production line. The speed of the extrusion motor can be adjusted through a frequency converter to control the extrusion speed and thickness of the product.

The advantage of DC motors is their high torque and stability when starting at low speeds. Some materials with poor fluidity are preferred by users to use DC motors. But DC motors require frequent maintenance of carbon brushes, which is relatively troublesome.

Compared to DC motors, AC motors have a higher proportion in the production line of cast film. The advantages of AC motors are simple structure, low cost, simple maintenance and repair, and low maintenance frequency. There are many series levels of AC frequency converters, and different series of frequency converters have different functional capacities and prices. It is common for frequency converters to be priced higher than AC motors.

3、 Introduction to the gearbox of the casting film production line

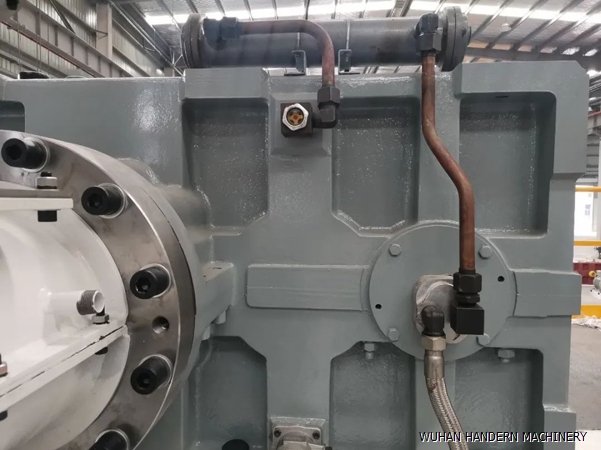

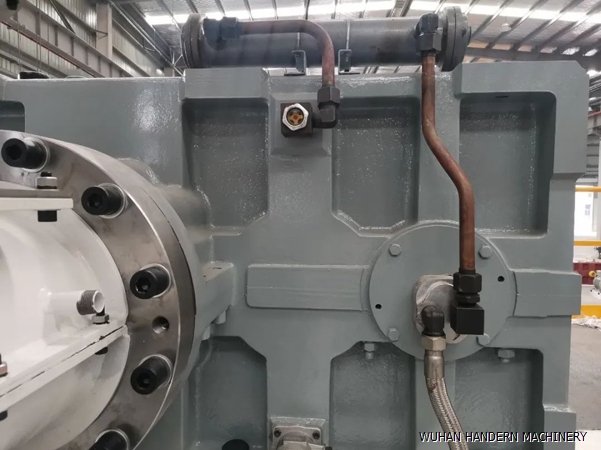

The gearbox is another important component in the casting film production line, used to slow down the speed of the extrusion motor and provide sufficient torque. If the gearbox is properly maintained, its service life is very long. The gearbox is usually driven by gears, and the gears and shaft parts are generally made of high-strength alloy steel, carburized, quenched, and ground. They are equipped with thrust blocks with high load-bearing capacity, and the appropriate rotation speed of the screw is achieved through the transmission ratio of the gears. The selection of gearbox should be determined based on the power and speed requirements of the extruder to ensure the normal operation of the extruder and product quality.

The gearbox is another important component in the casting film production line, used to slow down the speed of the extrusion motor and provide sufficient torque. If the gearbox is properly maintained, its service life is very long. The gearbox is usually driven by gears, and the gears and shaft parts are generally made of high-strength alloy steel, carburized, quenched, and ground. They are equipped with thrust blocks with high load-bearing capacity, and the appropriate rotation speed of the screw is achieved through the transmission ratio of the gears. The selection of gearbox should be determined based on the power and speed requirements of the extruder to ensure the normal operation of the extruder and product quality.

That's all for the difference between single screw and double screw in the casting film production line, as well as the introduction of knowledge about motors and gearboxes. In the later articles, I will also bring more knowledge in this area to everyone. I hope everyone can continue to pay attention to us.

Single screw casting film production line:

The single screw casting film production line uses a separate screw to feed plastic raw materials from the hopper into the screw barrel of the extruder, and the plastic raw materials are heated, melted, and mixed through the rotation of the screw. The single screw casting film production line is suitable for producing some simple film products, such as plastic bags, plastic films, etc.

Twin screw casting film production line:

The twin screw casting film production line adds an auxiliary screw on top of the single screw, and through the synergistic effect of the twin screws, it can better complete the melting, mixing, and extrusion of plastic raw materials. The twin screw casting film production line is suitable for producing complex thin film products, such as multi-layer composite films, functional films, etc.

2、 Introduction to Motors for Casting Film Production Line

The advantage of DC motors is their high torque and stability when starting at low speeds. Some materials with poor fluidity are preferred by users to use DC motors. But DC motors require frequent maintenance of carbon brushes, which is relatively troublesome.

Compared to DC motors, AC motors have a higher proportion in the production line of cast film. The advantages of AC motors are simple structure, low cost, simple maintenance and repair, and low maintenance frequency. There are many series levels of AC frequency converters, and different series of frequency converters have different functional capacities and prices. It is common for frequency converters to be priced higher than AC motors.

3、 Introduction to the gearbox of the casting film production line

That's all for the difference between single screw and double screw in the casting film production line, as well as the introduction of knowledge about motors and gearboxes. In the later articles, I will also bring more knowledge in this area to everyone. I hope everyone can continue to pay attention to us.

Author:admin