How are the grades of PP hollow boards divided

DATE:2024/12/23 11:18:15 / READ: / SOURCE:This station

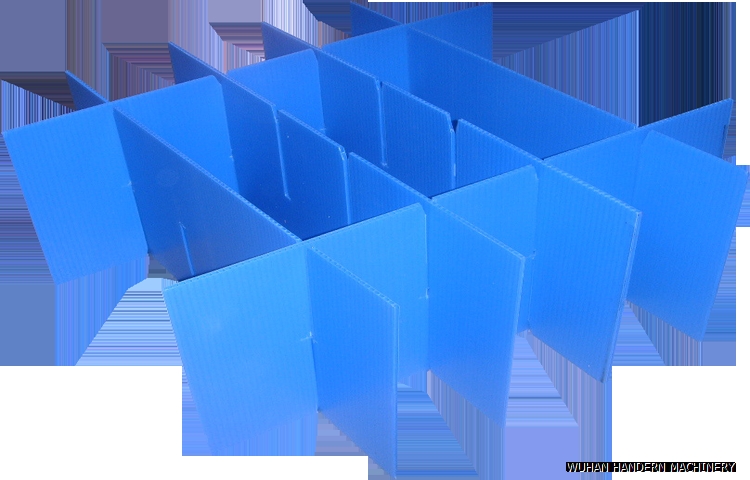

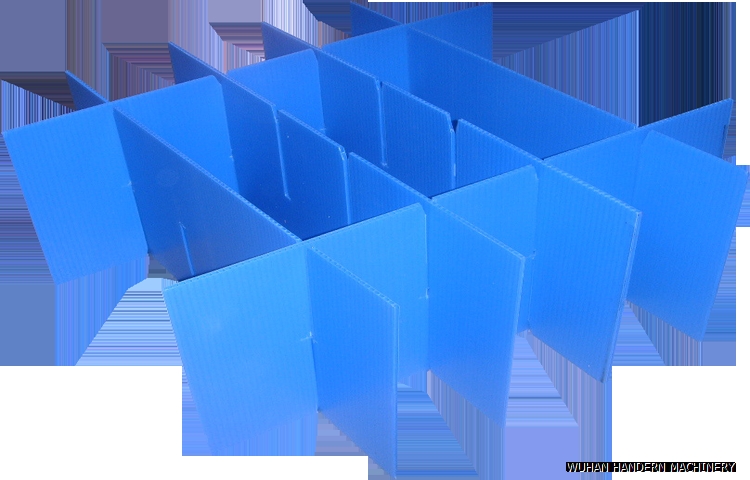

PP hollow board, usually made of polypropylene (PP) material through extrusion molding process, is a lightweight and sturdy board widely used in packaging, construction, advertising, transportation and other fields. The classification of PP hollow boards is mainly based on several key factors, including material, thickness, strength, application field, and physical properties. The following is a detailed explanation of the grading of PP hollow boards:

1. Material grade

1. Material grade

PP hollow boards are generally classified based on the quality of the raw materials. Common materials include recycled PP and raw material PP. The raw material PP usually has higher strength and better temperature resistance, so the grade of hollow boards made from it is relatively high. Recycled materials may have their strength and transparency affected by pollution and deterioration of physical properties during their production process.

2. Thickness grade

The thickness of PP hollow board is usually an important factor affecting its strength and performance. Generally speaking, thicker hollow boards (such as 5mm, 7mm, 10mm, etc.) have higher compressive strength and durability, and are suitable for applications that carry heavy objects. Thin hollow boards (such as 2mm and 3mm), although lightweight, are relatively fragile and suitable for some lightweight packaging and display purposes. Therefore, thickness is also commonly used to classify grades.

3. Tensile strength and compressive strength

3. Tensile strength and compressive strength

The grade of PP hollow board will also be based on its tensile strength and compressive strength. High strength hollow boards are usually used in environments with heavy loads or subjected to significant external forces, such as cushioning plates for transporting and storing heavy objects. This type of hollow board can improve its mechanical properties by modifying PP materials or enhancing structural design.

4. Application Fields

The classification of PP hollow boards is closely related to their application fields. The high transparency and flatness boards used in the advertising industry may have different technical standards from the hollow boards used in construction, packaging, and other fields. Specific applications may require specific quality standards, such as waterproof, fireproof, acid and alkali resistant properties, which can also affect the grading of hollow boards.

5. Physical characteristics

The physical properties of PP hollow boards, such as UV resistance, temperature resistance, and waterproof performance, are also important grading standards. Specially treated UV resistant hollow panels are suitable for outdoor advertising and prolonged exposure to sunlight. Hollow boards with high temperature resistance are suitable for applications that require high or low temperature resistance.

6. Standards and Certification

6. Standards and Certification

Industry standards and quality certification are also important criteria for classifying PP hollow board grades. Some countries or regions have established relevant product quality standards, specifying specific technical indicators for PP hollow boards, such as ASTM D5034, ISO 527, etc. These standards provide assurance for the quality of products in the market.

PP hollow boards are generally classified based on the quality of the raw materials. Common materials include recycled PP and raw material PP. The raw material PP usually has higher strength and better temperature resistance, so the grade of hollow boards made from it is relatively high. Recycled materials may have their strength and transparency affected by pollution and deterioration of physical properties during their production process.

2. Thickness grade

The thickness of PP hollow board is usually an important factor affecting its strength and performance. Generally speaking, thicker hollow boards (such as 5mm, 7mm, 10mm, etc.) have higher compressive strength and durability, and are suitable for applications that carry heavy objects. Thin hollow boards (such as 2mm and 3mm), although lightweight, are relatively fragile and suitable for some lightweight packaging and display purposes. Therefore, thickness is also commonly used to classify grades.

The grade of PP hollow board will also be based on its tensile strength and compressive strength. High strength hollow boards are usually used in environments with heavy loads or subjected to significant external forces, such as cushioning plates for transporting and storing heavy objects. This type of hollow board can improve its mechanical properties by modifying PP materials or enhancing structural design.

4. Application Fields

The classification of PP hollow boards is closely related to their application fields. The high transparency and flatness boards used in the advertising industry may have different technical standards from the hollow boards used in construction, packaging, and other fields. Specific applications may require specific quality standards, such as waterproof, fireproof, acid and alkali resistant properties, which can also affect the grading of hollow boards.

5. Physical characteristics

The physical properties of PP hollow boards, such as UV resistance, temperature resistance, and waterproof performance, are also important grading standards. Specially treated UV resistant hollow panels are suitable for outdoor advertising and prolonged exposure to sunlight. Hollow boards with high temperature resistance are suitable for applications that require high or low temperature resistance.

Industry standards and quality certification are also important criteria for classifying PP hollow board grades. Some countries or regions have established relevant product quality standards, specifying specific technical indicators for PP hollow boards, such as ASTM D5034, ISO 527, etc. These standards provide assurance for the quality of products in the market.

The classification of PP hollow boards is a complex process, mainly determined by the material, thickness, tensile and compressive strength, application field, physical properties, and corresponding standards and certifications.

Author:admin