What are the design difficulties of a biaxially oriented film production line

DATE:2024/12/20 11:10:08 / READ: / SOURCE:This station

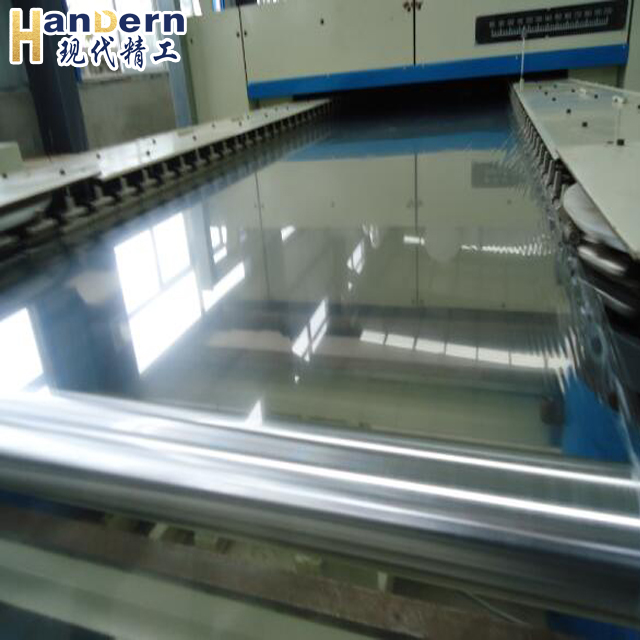

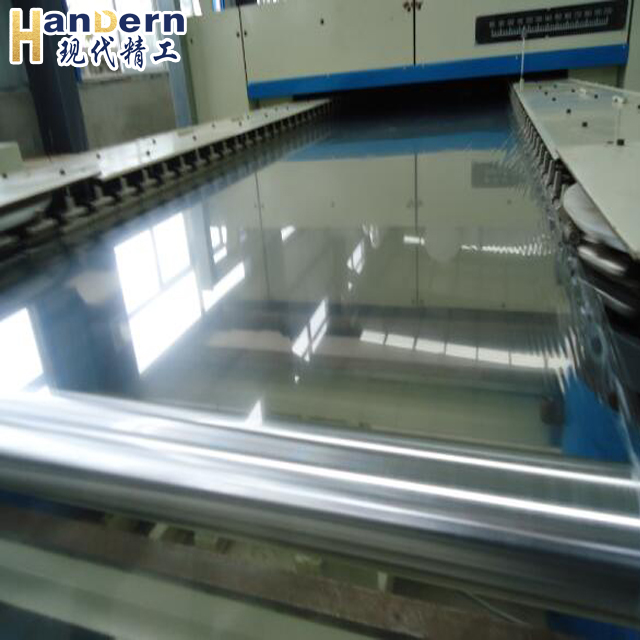

The design of a biaxially oriented film (BOPP/BOPET, etc.) production line is a complex and challenging engineering project that involves the integration of multiple key technologies and equipment. The following are some of the main difficulties in designing a biaxially oriented film production line:

1. Material selection and formula design

1. Material selection and formula design

The performance of biaxially oriented films mainly depends on the resin material and its formulation used. In the design process, it is necessary to select suitable polymers, such as polypropylene (PP) or polyester (PET), and combine different additives (such as antioxidants, anti UV agents, and anti-static agents) to obtain the desired physical and mechanical properties. This requires designers to have rich knowledge of materials science and a profound understanding of the performance of different materials during the stretching process.

2. Stretching control

Bi directional stretching is the core process of producing films, involving precise control of multiple parameters such as barrel temperature, stretching ratio, and stretching speed. Designers need to ensure that the machine can stably perform precise longitudinal and transverse stretching, and these two directions of stretching need to be synchronized to achieve the desired membrane structure and performance. The control system must have a high degree of flexibility and accuracy to adjust under different production conditions.

3. Coordination and integration of equipment

3. Coordination and integration of equipment

A biaxially oriented film production line usually consists of multiple parts such as extruders, cooling rollers, stretching equipment, and rewinding machines. In design, the coordination between devices, the design of transmission systems, and the coordination of various modules become key. Designers must ensure that each device can seamlessly connect during the production process and maintain consistent production parameters and speeds to ensure the uniformity and stability of the membrane.

4. Temperature control system

The production process of thin films requires precise temperature control, especially in the extruder, stretching area, and cooling stage. Uneven temperature can lead to unstable film performance and even loss of overall quality. Therefore, designing an efficient temperature control system is the key to ensuring product quality. An efficient cooling system can prevent deformation or wrinkling of the film after stretching.

The difficulty in designing a biaxially oriented film production line lies in various technical challenges, including material selection, stretching control, equipment coordination, temperature control, etc. To solve these difficulties, the design team needs to have solid professional knowledge and engineering experience, while actively adopting the latest technology and equipment to ensure the efficient operation of the production line and the reliability of product quality.

The difficulty in designing a biaxially oriented film production line lies in various technical challenges, including material selection, stretching control, equipment coordination, temperature control, etc. To solve these difficulties, the design team needs to have solid professional knowledge and engineering experience, while actively adopting the latest technology and equipment to ensure the efficient operation of the production line and the reliability of product quality.

The performance of biaxially oriented films mainly depends on the resin material and its formulation used. In the design process, it is necessary to select suitable polymers, such as polypropylene (PP) or polyester (PET), and combine different additives (such as antioxidants, anti UV agents, and anti-static agents) to obtain the desired physical and mechanical properties. This requires designers to have rich knowledge of materials science and a profound understanding of the performance of different materials during the stretching process.

2. Stretching control

Bi directional stretching is the core process of producing films, involving precise control of multiple parameters such as barrel temperature, stretching ratio, and stretching speed. Designers need to ensure that the machine can stably perform precise longitudinal and transverse stretching, and these two directions of stretching need to be synchronized to achieve the desired membrane structure and performance. The control system must have a high degree of flexibility and accuracy to adjust under different production conditions.

A biaxially oriented film production line usually consists of multiple parts such as extruders, cooling rollers, stretching equipment, and rewinding machines. In design, the coordination between devices, the design of transmission systems, and the coordination of various modules become key. Designers must ensure that each device can seamlessly connect during the production process and maintain consistent production parameters and speeds to ensure the uniformity and stability of the membrane.

4. Temperature control system

The production process of thin films requires precise temperature control, especially in the extruder, stretching area, and cooling stage. Uneven temperature can lead to unstable film performance and even loss of overall quality. Therefore, designing an efficient temperature control system is the key to ensuring product quality. An efficient cooling system can prevent deformation or wrinkling of the film after stretching.

Author:admin