How to do anti-static treatment for plastic calcium plastic board production line

DATE:2024/11/27 10:54:57 / READ: / SOURCE:This station

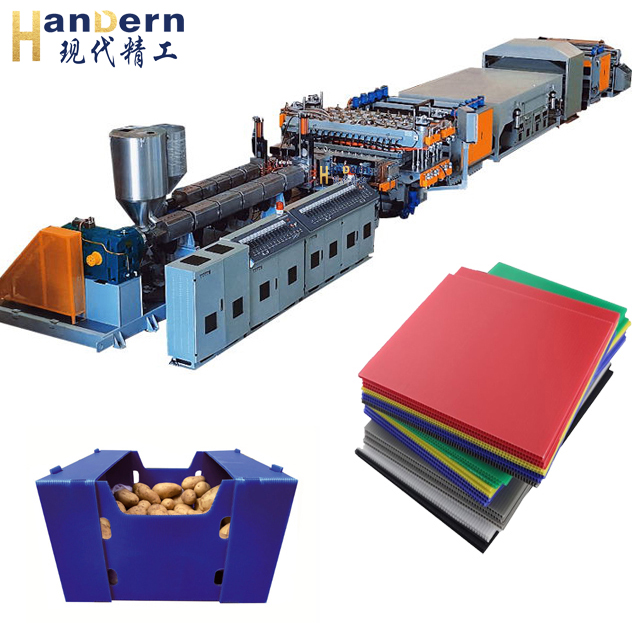

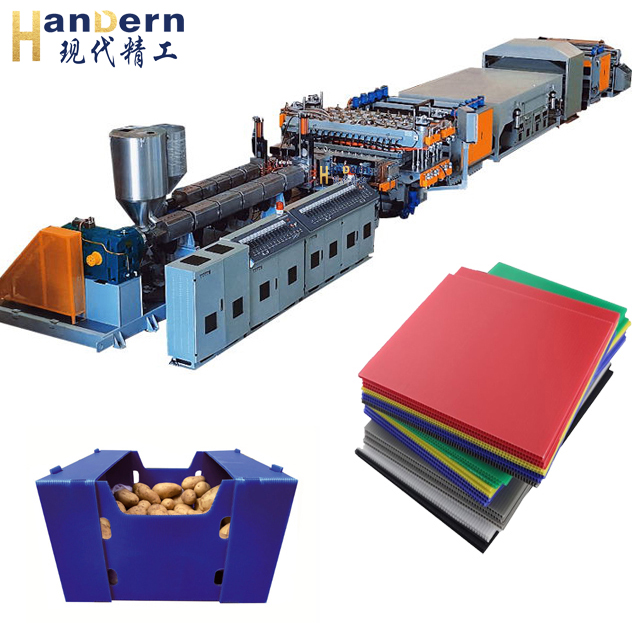

Plastic calcium plastic board is an environmentally friendly material mainly composed of calcium carbonate and polyethylene or polypropylene, widely used in packaging, construction, advertising and other fields. Anti static treatment is an important part of calcium plastic board production, especially in electronic product packaging and industry applications, where static electricity may have an impact on product safety and quality. The following are the main methods and processes for anti-static treatment of plastic calcium plastic board production line.

1. Application of anti-static additives

1. Application of anti-static additives

The most effective anti-static method in the production process of plastic calcium plastic sheets is to add anti-static agents to the raw materials. Antistatic additives are usually hydrophilic polymers or surfactants that can change the electrical properties of the calcium plastic plate surface, reduce surface resistance, and thus reduce the accumulation of static electricity. Common anti-static agents include:

Anionic anti-static agent: suitable for strong anti-static needs, can effectively improve surface conductivity.

Non ionic anti-static agent: high safety, suitable for applications in industries such as food, but the anti-static effect is relatively weak.

2. Manufacturing process adjustment

In the production process of calcium plastic sheets, the anti-static effect can be further enhanced by adjusting the manufacturing process. For example:

Optimization of extrusion process: During the extrusion process, the molecular structure of the product surface can be improved through reasonable design of temperature control and cooling rate, thereby enhancing its conductivity.

Combining molding technology: The molding methods used (such as blown film, casting, etc.) can also have an impact on electrostatic discharge. Reasonable selection of molding equipment and parameters can reduce the risk of electrostatic accumulation.

3. Surface treatment technology

3. Surface treatment technology

After the product is formed, physical or chemical treatment can be carried out on the surface of the calcium plastic board to enhance its anti-static performance. Common handling methods include:

Plasma treatment: By using plasma technology to change the chemical properties of the material surface, its anti-static effect is improved.

Coating treatment: Applying an anti-static coating on the surface of the calcium plastic board can form a protective film that extends on the sub surface, effectively preventing the generation of static electricity.

4. Humidity control

Humidity has a significant impact on static electricity generation. When the relative humidity is high, the moisture in the air can effectively reduce the accumulation of static electricity. Therefore, appropriate control of environmental humidity is an important part of anti-static measures in production environments and product storage. Humidification equipment can be used to adjust the humidity in the production workshop to reduce the generation of static electricity.

5. Performance testing

Establish a comprehensive quality control system during the production process and conduct regular testing of the anti-static performance of calcium plastic sheets. By testing the surface resistance and volume resistance values, confirm the effectiveness of anti-static measures and ensure that the final product meets relevant industry standards.

The anti-static treatment of plastic calcium plastic board is a comprehensive process that involves the application of anti-static additives, optimization of manufacturing processes, adoption of surface treatment technologies, humidity control, and other aspects. These measures can effectively prevent the adverse effects of static electricity on products and improve the safety and reliability of calcium plastic board applications.

The anti-static treatment of plastic calcium plastic board is a comprehensive process that involves the application of anti-static additives, optimization of manufacturing processes, adoption of surface treatment technologies, humidity control, and other aspects. These measures can effectively prevent the adverse effects of static electricity on products and improve the safety and reliability of calcium plastic board applications.

The most effective anti-static method in the production process of plastic calcium plastic sheets is to add anti-static agents to the raw materials. Antistatic additives are usually hydrophilic polymers or surfactants that can change the electrical properties of the calcium plastic plate surface, reduce surface resistance, and thus reduce the accumulation of static electricity. Common anti-static agents include:

Anionic anti-static agent: suitable for strong anti-static needs, can effectively improve surface conductivity.

Non ionic anti-static agent: high safety, suitable for applications in industries such as food, but the anti-static effect is relatively weak.

2. Manufacturing process adjustment

In the production process of calcium plastic sheets, the anti-static effect can be further enhanced by adjusting the manufacturing process. For example:

Optimization of extrusion process: During the extrusion process, the molecular structure of the product surface can be improved through reasonable design of temperature control and cooling rate, thereby enhancing its conductivity.

Combining molding technology: The molding methods used (such as blown film, casting, etc.) can also have an impact on electrostatic discharge. Reasonable selection of molding equipment and parameters can reduce the risk of electrostatic accumulation.

After the product is formed, physical or chemical treatment can be carried out on the surface of the calcium plastic board to enhance its anti-static performance. Common handling methods include:

Plasma treatment: By using plasma technology to change the chemical properties of the material surface, its anti-static effect is improved.

Coating treatment: Applying an anti-static coating on the surface of the calcium plastic board can form a protective film that extends on the sub surface, effectively preventing the generation of static electricity.

4. Humidity control

Humidity has a significant impact on static electricity generation. When the relative humidity is high, the moisture in the air can effectively reduce the accumulation of static electricity. Therefore, appropriate control of environmental humidity is an important part of anti-static measures in production environments and product storage. Humidification equipment can be used to adjust the humidity in the production workshop to reduce the generation of static electricity.

5. Performance testing

Establish a comprehensive quality control system during the production process and conduct regular testing of the anti-static performance of calcium plastic sheets. By testing the surface resistance and volume resistance values, confirm the effectiveness of anti-static measures and ensure that the final product meets relevant industry standards.

Author:admin