What is the difference between semi-automatic and fully automatic laminating machines

DATE:2024/11/20 10:05:06 / READ: / SOURCE:This station

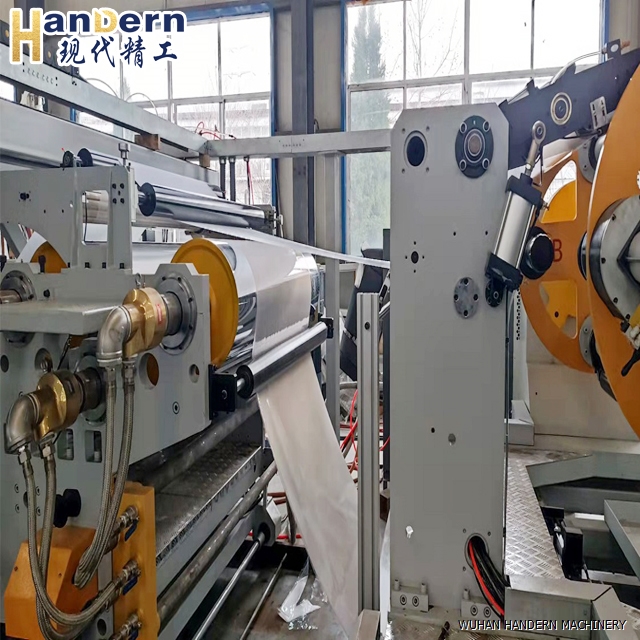

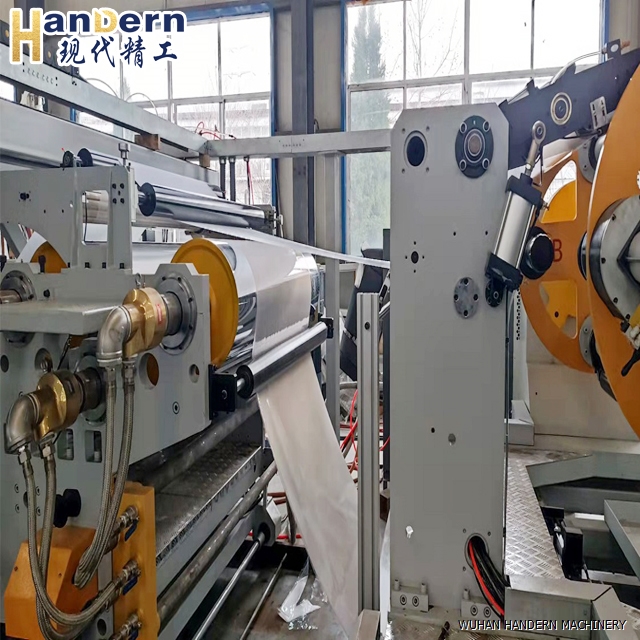

The laminating machine is an indispensable and important equipment in the modern packaging industry, widely used in the packaging of products such as food, medicine, and daily necessities. There are significant differences between semi-automatic and fully automatic laminating machines in terms of functionality, operation, efficiency, and flexibility. Choosing the appropriate type is crucial for improving production efficiency and product quality.

1. Operation method

1. Operation method

Semi automatic laminating machine: As its name suggests, a semi-automatic laminating machine requires manual intervention to complete certain steps. Although the equipment is automated to complete the main composite process, manual operations are still required for feeding, retrieving, cutting, and organizing. This operation method requires operators to possess certain professional skills and experience.

Fully automatic laminating machine: The fully automatic laminating machine realizes the full automation of the production process, from the feeding of raw materials to the discharge of finished products, the entire process requires almost no manual intervention. The equipment automatically adjusts various parameters through an advanced control system to ensure the continuity and stability of production.

2. Efficiency and output

Semi automatic laminating machine: Due to the need for manual operation, the production efficiency of semi-automatic equipment is relatively low, especially in environments with high production demand. The limitations of manual labor may lead to a slow pace of the production line, which in turn affects the overall production efficiency.

Fully automatic laminating machine: Fully automatic equipment can achieve higher production efficiency, usually able to complete larger quantities of product production at a faster speed, especially suitable for large-scale production needs. Its rapid production capacity can also significantly reduce production costs.

3. Flexibility and adaptability

3. Flexibility and adaptability

Semi automatic laminating machine: This type of equipment has high flexibility and can be quickly adjusted according to different product requirements to adapt to raw materials of various weights, thicknesses, and widths. Therefore, in small-scale and multi variety production environments, semi-automatic laminating machines exhibit better adaptability.

Fully automatic laminating machine: Although modern fully automatic machines are designed with flexibility in mind, the conversion to multi variety and small batch production may take time, especially when the equipment needs to be re debugged and reconfigured. Therefore, in situations where product changes are frequent, the flexibility of adjustment may be relatively reduced.

4. Investment and maintenance costs

Semi automatic laminating machine: Relatively speaking, the procurement cost of this type of equipment is relatively low, suitable for start-up enterprises or small production lines. However, as it still requires manual operation, it may lead to an increase in labor costs in the long run.

Fully automatic laminating machine: The initial investment of fully automatic equipment is relatively high, suitable for medium and large enterprises with stable and high-yield demand. Although they may reduce labor costs in operation, equipment maintenance and troubleshooting require higher technical support and professional training.

Semi automatic and fully automatic laminating machines each have their own advantages and disadvantages, and the selection of suitable equipment should be based on factors such as the production needs, budget, product types, and production scale of the enterprise. The semi-automatic laminating machine is more suitable for small-scale and highly flexible production environments, while the fully automatic laminating machine is suitable for large-scale and high-efficiency production lines. The final choice should revolve around the long-term development strategy of the enterprise, ensuring that the equipment can maximize productivity and economic benefits.

Semi automatic and fully automatic laminating machines each have their own advantages and disadvantages, and the selection of suitable equipment should be based on factors such as the production needs, budget, product types, and production scale of the enterprise. The semi-automatic laminating machine is more suitable for small-scale and highly flexible production environments, while the fully automatic laminating machine is suitable for large-scale and high-efficiency production lines. The final choice should revolve around the long-term development strategy of the enterprise, ensuring that the equipment can maximize productivity and economic benefits.

Semi automatic laminating machine: As its name suggests, a semi-automatic laminating machine requires manual intervention to complete certain steps. Although the equipment is automated to complete the main composite process, manual operations are still required for feeding, retrieving, cutting, and organizing. This operation method requires operators to possess certain professional skills and experience.

Fully automatic laminating machine: The fully automatic laminating machine realizes the full automation of the production process, from the feeding of raw materials to the discharge of finished products, the entire process requires almost no manual intervention. The equipment automatically adjusts various parameters through an advanced control system to ensure the continuity and stability of production.

2. Efficiency and output

Semi automatic laminating machine: Due to the need for manual operation, the production efficiency of semi-automatic equipment is relatively low, especially in environments with high production demand. The limitations of manual labor may lead to a slow pace of the production line, which in turn affects the overall production efficiency.

Fully automatic laminating machine: Fully automatic equipment can achieve higher production efficiency, usually able to complete larger quantities of product production at a faster speed, especially suitable for large-scale production needs. Its rapid production capacity can also significantly reduce production costs.

Semi automatic laminating machine: This type of equipment has high flexibility and can be quickly adjusted according to different product requirements to adapt to raw materials of various weights, thicknesses, and widths. Therefore, in small-scale and multi variety production environments, semi-automatic laminating machines exhibit better adaptability.

Fully automatic laminating machine: Although modern fully automatic machines are designed with flexibility in mind, the conversion to multi variety and small batch production may take time, especially when the equipment needs to be re debugged and reconfigured. Therefore, in situations where product changes are frequent, the flexibility of adjustment may be relatively reduced.

4. Investment and maintenance costs

Semi automatic laminating machine: Relatively speaking, the procurement cost of this type of equipment is relatively low, suitable for start-up enterprises or small production lines. However, as it still requires manual operation, it may lead to an increase in labor costs in the long run.

Fully automatic laminating machine: The initial investment of fully automatic equipment is relatively high, suitable for medium and large enterprises with stable and high-yield demand. Although they may reduce labor costs in operation, equipment maintenance and troubleshooting require higher technical support and professional training.

Author:admin