What are the requirements for the substrate of the paper plastic laminating machine

DATE:2024/11/16 10:07:08 / READ: / SOURCE:This station

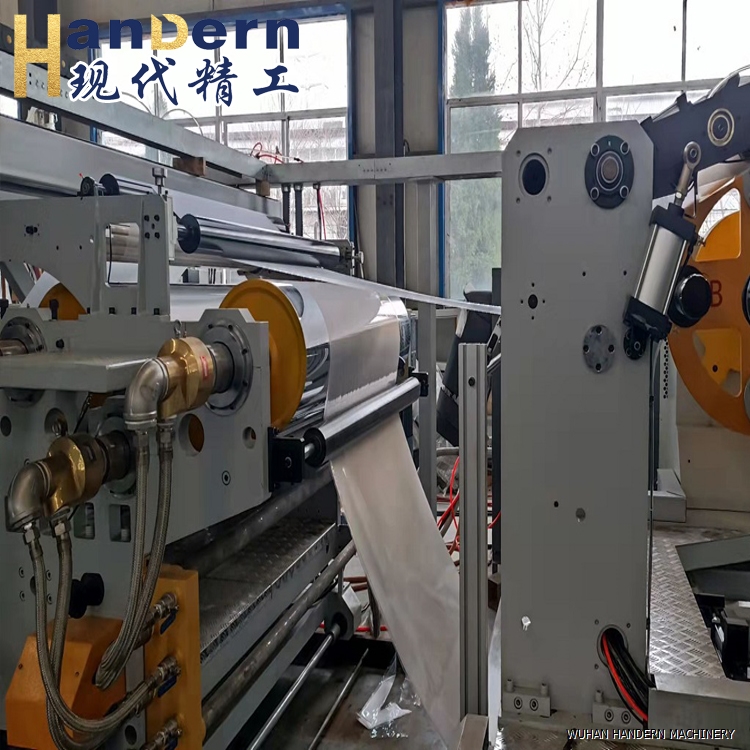

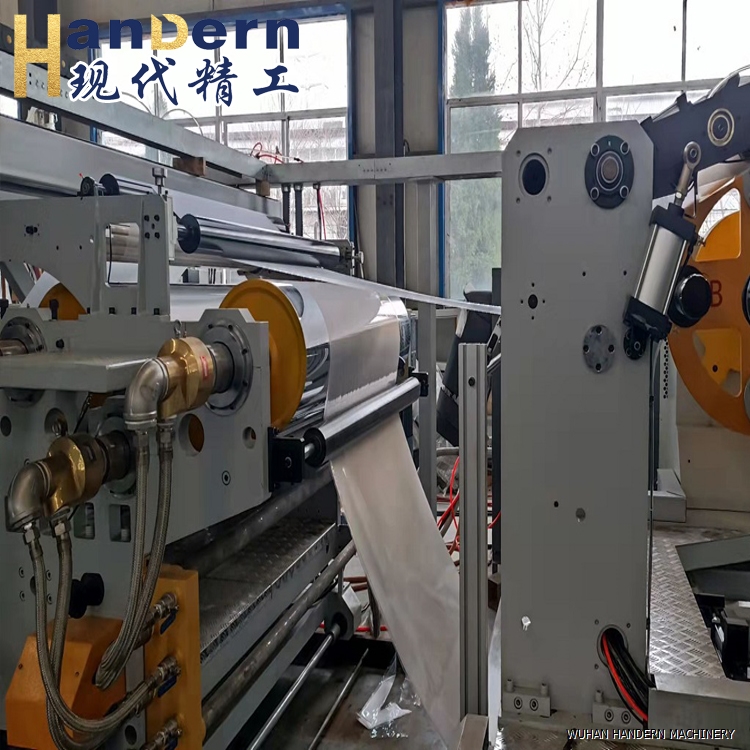

Paper plastic laminating machine is a device used for laminating paper and plastic film, widely used in the packaging industry, especially in food packaging and daily consumer goods. In order to ensure the quality and performance of the composite product, the paper plastic laminating machine has a series of requirements for the substrate (paper and plastic film). The following will elaborate on these requirements in detail.

1. Physical properties of the substrate

1. Physical properties of the substrate

Strength and toughness

The strength and toughness of the substrate are the basic requirements to ensure the composite effect. Paper needs to have good tear strength and compressive strength to withstand the mechanical pressure and stress that may be experienced during compounding and subsequent processing. Plastic film should also have a certain tensile strength to ensure that it is not easily broken during processing and use.

Balance of thickness

The thickness of the substrate should be uniform, which helps to ensure the uniformity of adhesion between the paper and plastic layers during the composite process, avoid unevenness, and improve the overall quality of the composite product.

2. Chemical properties of the substrate

Surface energy and adhesive properties

The surface energy of paper and plastic film has a significant impact on the composite effect. A higher surface energy can improve the wetting and adhesion of the coating adhesive, thereby enhancing the firmness of the composite. Therefore, when selecting a substrate, surface treatment processes such as coating, bleaching, and polishing should be considered to enhance its surface energy.

Temperature resistance and chemical resistance

The temperature and chemical resistance of the substrate are also very important in the composite process. Based on the temperature and humidity during the coating process, the substrate should be able to withstand certain temperature changes without deformation or degradation. In addition, in certain usage environments, the substrate also needs to have certain oil, water, and acid alkali resistance properties to ensure the applicability of the final product.

3. Environmental requirements for substrates

3. Environmental requirements for substrates

With the increasing awareness of environmental protection, the environmental performance of substrates is also an important consideration. Paper should comply with green environmental standards, ensure its sustainable source, and be free of harmful substances during the production process. Plastic film should also prioritize the use of environmentally friendly materials that comply with relevant regulations, such as biodegradable PLA film, to meet the market's demand for eco-friendly packaging.

4. Printing and coating performance

If the substrate needs to be printed or coated before lamination, its printing performance should be considered. The ink absorption of paper should be appropriate to avoid blurring or fading of printed patterns; The coating properties of plastic film should also be good to ensure uniform coating and improve adhesive strength.

5. Economy and availability

Finally, the economy and availability of the substrate are also factors that cannot be ignored. Choosing paper and film with higher cost-effectiveness can not only reduce production costs, but also consider the stability of supply in the market to ensure production continuity.

The requirements for the substrate of the paper plastic laminating machine include physical properties (strength and uniformity), chemical properties (surface energy and chemical resistance), environmental requirements, printing and coating performance, as well as economy and availability. Only by selecting substrates that meet these requirements can we ensure that composite products have good quality and performance, and meet market demand.

The requirements for the substrate of the paper plastic laminating machine include physical properties (strength and uniformity), chemical properties (surface energy and chemical resistance), environmental requirements, printing and coating performance, as well as economy and availability. Only by selecting substrates that meet these requirements can we ensure that composite products have good quality and performance, and meet market demand.

Strength and toughness

The strength and toughness of the substrate are the basic requirements to ensure the composite effect. Paper needs to have good tear strength and compressive strength to withstand the mechanical pressure and stress that may be experienced during compounding and subsequent processing. Plastic film should also have a certain tensile strength to ensure that it is not easily broken during processing and use.

Balance of thickness

The thickness of the substrate should be uniform, which helps to ensure the uniformity of adhesion between the paper and plastic layers during the composite process, avoid unevenness, and improve the overall quality of the composite product.

2. Chemical properties of the substrate

Surface energy and adhesive properties

The surface energy of paper and plastic film has a significant impact on the composite effect. A higher surface energy can improve the wetting and adhesion of the coating adhesive, thereby enhancing the firmness of the composite. Therefore, when selecting a substrate, surface treatment processes such as coating, bleaching, and polishing should be considered to enhance its surface energy.

Temperature resistance and chemical resistance

The temperature and chemical resistance of the substrate are also very important in the composite process. Based on the temperature and humidity during the coating process, the substrate should be able to withstand certain temperature changes without deformation or degradation. In addition, in certain usage environments, the substrate also needs to have certain oil, water, and acid alkali resistance properties to ensure the applicability of the final product.

With the increasing awareness of environmental protection, the environmental performance of substrates is also an important consideration. Paper should comply with green environmental standards, ensure its sustainable source, and be free of harmful substances during the production process. Plastic film should also prioritize the use of environmentally friendly materials that comply with relevant regulations, such as biodegradable PLA film, to meet the market's demand for eco-friendly packaging.

4. Printing and coating performance

If the substrate needs to be printed or coated before lamination, its printing performance should be considered. The ink absorption of paper should be appropriate to avoid blurring or fading of printed patterns; The coating properties of plastic film should also be good to ensure uniform coating and improve adhesive strength.

5. Economy and availability

Finally, the economy and availability of the substrate are also factors that cannot be ignored. Choosing paper and film with higher cost-effectiveness can not only reduce production costs, but also consider the stability of supply in the market to ensure production continuity.

Author:admin