What is the preheating temperature for the plastic hollow board production line

DATE:2024/11/12 9:59:57 / READ: / SOURCE:This station

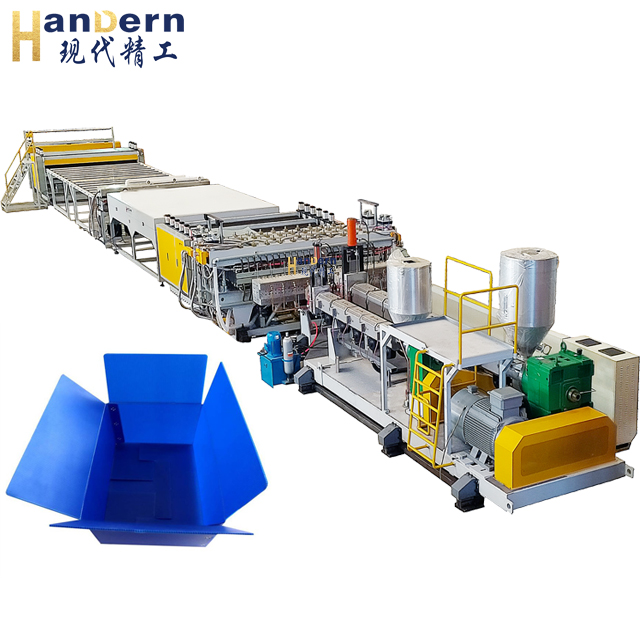

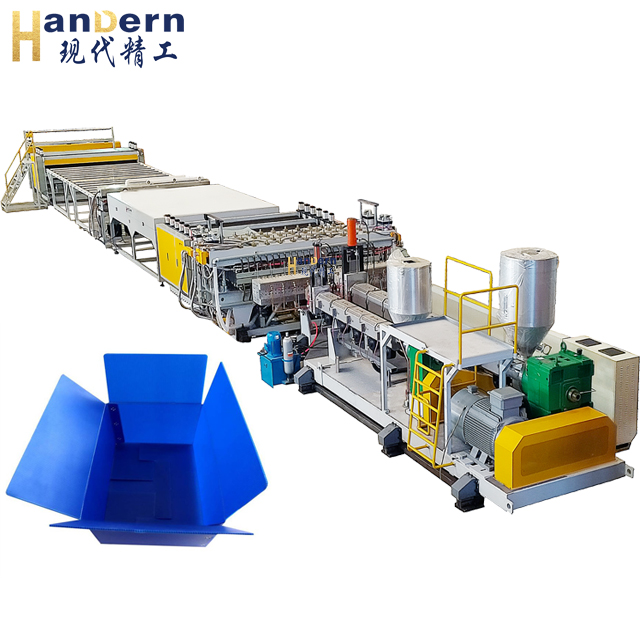

The preheating temperature of the plastic hollow board production line is a crucial parameter that directly affects the molding quality and final product performance during the production process. Hollow board production mainly uses plastic materials such as polypropylene (PP) and polyethylene (PE) as raw materials, and forms hollow structured boards through processes such as extrusion, molding, and cooling. Therefore, appropriate preheating temperature can help improve the flowability of plastic materials and reduce molding defects.

1、 Factors affecting preheating temperature

1、 Factors affecting preheating temperature

Material type: Different types of plastic materials have different melting points and flow properties. For example, the melting temperature of polypropylene is usually between 160 ° C and 180 ° C, while polyethylene is slightly lower. Therefore, the actual preheating temperature needs to be adjusted appropriately according to the type of raw material.

Production process: The design of the production line and process parameters also affect the setting of preheating temperature. For example, some high-performance production lines may choose higher preheating temperatures to increase production speed, while quality oriented production lines may use lower temperatures to ensure product quality.

Production speed: At high production speeds, the material has a shorter residence time in the mold, so a higher preheating temperature is required to ensure that the material can flow and fully form in a shorter period of time.

2、 Appropriate preheating temperature range

2、 Appropriate preheating temperature range

Generally speaking, the preheating temperature range for plastic hollow board production lines is between 120 ° C and 160 ° C. The temperature within this range helps to improve the fluidity of the plastic, enabling it to better fill the mold. In specific operations, the following are recommended preheating temperatures for different materials:

Polypropylene (PP): usually set between 140 ° C and 160 ° C to ensure good flowability and molding effect.

In practical operation, the preheating temperature is not constant. During the production process, operators need to make adjustments based on real-time monitoring data, such as observing the molding quality, fluidity, and feeding status of the product. It is necessary to adjust the preheating temperature in a timely manner if the material flow is not smooth or the molding is poor.

4、 Precautions

4、 Precautions

Temperature uniformity: Ensure that the preheating equipment can maintain uniform temperature, avoid local overheating or insufficient temperature, and prevent material defects during molding.

Equipment selection: Use high-performance preheating equipment, such as infrared heaters or hot air circulation systems, to improve thermal efficiency and achieve rapid and stable temperature.

Material storage: Pay attention to the storage conditions of plastic raw materials, keep them dry, prevent moisture absorption, and thus affect the preheating effect and product quality.

Proper preheating temperature is an important factor in achieving high-quality production in plastic hollow board production lines. Flexible adjustment of preheating temperature based on different material types, production processes, and actual production conditions can significantly improve product quality and production efficiency. This requires operators to have certain experience and skills to ensure the stable operation of the production line.

Material type: Different types of plastic materials have different melting points and flow properties. For example, the melting temperature of polypropylene is usually between 160 ° C and 180 ° C, while polyethylene is slightly lower. Therefore, the actual preheating temperature needs to be adjusted appropriately according to the type of raw material.

Production process: The design of the production line and process parameters also affect the setting of preheating temperature. For example, some high-performance production lines may choose higher preheating temperatures to increase production speed, while quality oriented production lines may use lower temperatures to ensure product quality.

Production speed: At high production speeds, the material has a shorter residence time in the mold, so a higher preheating temperature is required to ensure that the material can flow and fully form in a shorter period of time.

Generally speaking, the preheating temperature range for plastic hollow board production lines is between 120 ° C and 160 ° C. The temperature within this range helps to improve the fluidity of the plastic, enabling it to better fill the mold. In specific operations, the following are recommended preheating temperatures for different materials:

Polypropylene (PP): usually set between 140 ° C and 160 ° C to ensure good flowability and molding effect.

Polyethylene (PE): can be set between 120 ° C and 140 ° C to prevent overheating and degradation.

In practical operation, the preheating temperature is not constant. During the production process, operators need to make adjustments based on real-time monitoring data, such as observing the molding quality, fluidity, and feeding status of the product. It is necessary to adjust the preheating temperature in a timely manner if the material flow is not smooth or the molding is poor.

Temperature uniformity: Ensure that the preheating equipment can maintain uniform temperature, avoid local overheating or insufficient temperature, and prevent material defects during molding.

Equipment selection: Use high-performance preheating equipment, such as infrared heaters or hot air circulation systems, to improve thermal efficiency and achieve rapid and stable temperature.

Material storage: Pay attention to the storage conditions of plastic raw materials, keep them dry, prevent moisture absorption, and thus affect the preheating effect and product quality.

Proper preheating temperature is an important factor in achieving high-quality production in plastic hollow board production lines. Flexible adjustment of preheating temperature based on different material types, production processes, and actual production conditions can significantly improve product quality and production efficiency. This requires operators to have certain experience and skills to ensure the stable operation of the production line.

Author:admin