How many does a complete plastic hollow board production line weigh

DATE:2024/11/11 11:49:25 / READ: / SOURCE:This station

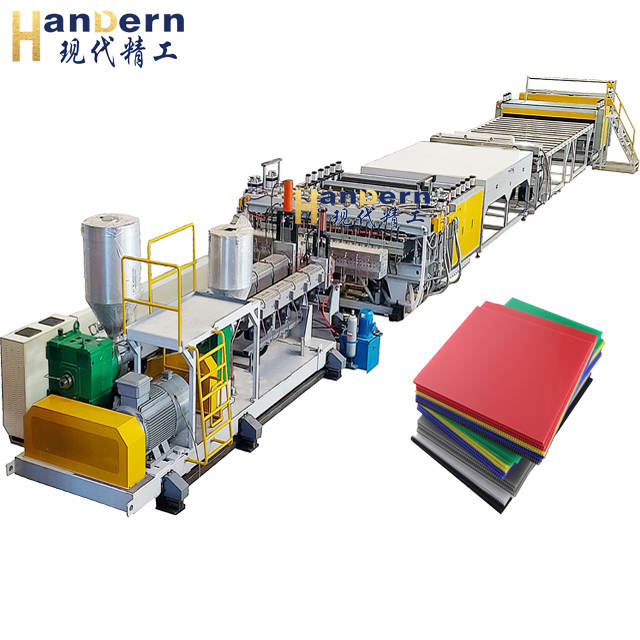

The weight of a complete plastic hollow board production line varies depending on its design, equipment type, scale, and configuration. Generally speaking, a plastic hollow board production line consists of several key components, including extruders, molds, cooling systems, cutting machines, conveying systems, and control systems. The following is a detailed introduction to these components and an estimate of the total weight of the production line.

1. Extruder

The extruder is the core equipment of the plastic hollow board production line, responsible for heating, melting, and extruding raw plastics (such as polypropylene PP) into shapes. According to the size and model of the extruder, its weight is usually between 1 ton and 8 tons. The larger the power and processing capacity of a large extruder, the heavier its weight tends to be.

2. Mold

Molds are used to form specific structures and sizes of hollow boards, usually customized according to customer needs. The weight of the mold is relatively light, usually between a few hundred kilograms and 2 tons, depending on the complexity and material of the mold.

3. Cooling system

The cooling system is used to reduce the temperature of the hollow board to ensure its stability after molding. The cooling device includes a water tank, a water pump, and a cooling tower. The overall weight of a cooling system typically ranges from 500 kilograms to 2 tons, depending on the system design and scale.

4. Cutting machine

The cutting machine is used to cut the formed hollow board into the required length, and its weight is generally between 500 kilograms and 2 tons. Small cutting machines are relatively light, while efficient automated cutting machines are heavier.

The conveying system is used to move raw materials and finished products between various parts of the production line. According to the design, the composition of the conveying system may include belt conveyors, elevators, etc., with a total weight ranging from 200 kilograms to 1 ton.

6. Control system

The control system usually consists of a computer console, PLC controller, and related power distribution devices. Although it is relatively lightweight, usually weighing a few hundred kilograms, it is still an essential part of the entire production line.

7. Comprehensive weight of the complete production line

Taking into account the weight of all the core equipment mentioned above, the total weight of a complete plastic hollow board production line is usually between 5 tons and 20 tons, depending on the scale and configuration of the production line. For example, a small basic production line may weigh less than 5 tons, while a large fully automated production line may weigh over 20 tons.

Transportation and installation are also important factors to consider. Due to the large weight of various parts of the production line, specific transportation vehicles and installation equipment are usually required to complete the handling and installation of the equipment. In addition, the infrastructure of the production line, such as brackets and foundations, may require additional building materials and processes.

conclusion

In summary, the weight of a complete plastic hollow board production line is determined by the combination of multiple key equipment and systems, typically ranging from 5 tons to 20 tons. When purchasing and installing production lines, enterprises need to carefully consider the total weight of equipment and related transportation and infrastructure requirements to ensure that the production line can be safely and smoothly put into production.

Author:admin