What are the types of stretch film production lines

DATE:2024/10/31 9:44:36 / READ: / SOURCE:This station

The production lines for stretch film can be classified according to different stretching directions, mainly divided into horizontal stretch film production lines and vertical stretch film production lines. There are some significant differences between these two types of production lines in terms of process, structure, and final product characteristics.

1. Horizontal stretch film production line

1. Horizontal stretch film production line

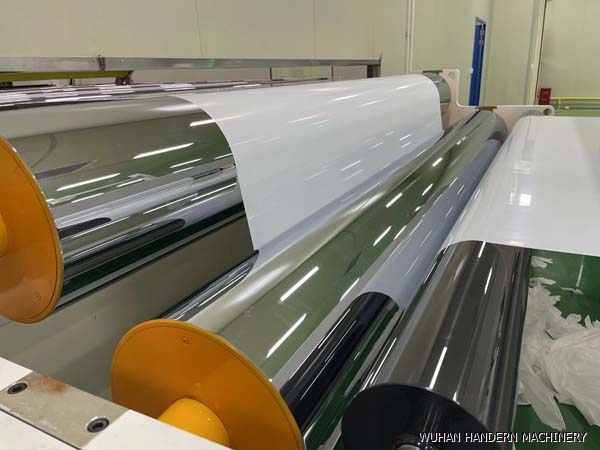

Definition and Process: A horizontal stretching film production line refers to the process where the film is mainly stretched along the horizontal direction during production. This production line usually adopts single-layer or multi-layer co extrusion method, where the polymer is melted and formed into thin sheets through a mold, and then stretched on a horizontal plane through a rolling device.

characteristic:

Uniformity: Horizontal stretching results in good uniformity of the film in the transverse direction. Due to the relatively balanced distribution of forces, the thickness and mechanical properties of the film can be effectively controlled.

Widely used: This film is widely used in packaging, agricultural film, industrial film and other fields, and is favored for its good tear resistance and breathability.

Definition and process: The vertical stretching film production line refers to the main stretching of the film along the vertical direction during the production process. This usually involves melting the polymer through an extruder and pushing it into a mold, followed by longitudinal stretching to give the film the desired properties.

characteristic:

High strength characteristics: Thin films that have been vertically stretched typically have high strength and excellent tear resistance, making them particularly suitable for applications that require high strength.

Dimensional stability: This stretching method can reduce the dimensional changes of the film to a certain extent during subsequent processing, improving the stability of the product.

Although uniaxial stretching is the main method, many production lines can also achieve biaxial stretching, usually by combining the above two methods to improve the performance of the film. Bi directional stretching can not only improve the tensile strength, transparency, and heat resistance of the film, but also achieve more uniform mechanical properties. This type of production line is receiving increasing attention because it can combine the advantages of horizontal and vertical stretching under certain conditions, providing higher quality films.

Definition and Process: A horizontal stretching film production line refers to the process where the film is mainly stretched along the horizontal direction during production. This production line usually adopts single-layer or multi-layer co extrusion method, where the polymer is melted and formed into thin sheets through a mold, and then stretched on a horizontal plane through a rolling device.

characteristic:

Uniformity: Horizontal stretching results in good uniformity of the film in the transverse direction. Due to the relatively balanced distribution of forces, the thickness and mechanical properties of the film can be effectively controlled.

Widely used: This film is widely used in packaging, agricultural film, industrial film and other fields, and is favored for its good tear resistance and breathability.

Process equipment: The equipment configuration is relatively simple, the production process is easy to operate, and it is suitable for large-scale production.

Definition and process: The vertical stretching film production line refers to the main stretching of the film along the vertical direction during the production process. This usually involves melting the polymer through an extruder and pushing it into a mold, followed by longitudinal stretching to give the film the desired properties.

characteristic:

High strength characteristics: Thin films that have been vertically stretched typically have high strength and excellent tear resistance, making them particularly suitable for applications that require high strength.

Dimensional stability: This stretching method can reduce the dimensional changes of the film to a certain extent during subsequent processing, improving the stability of the product.

Complex process: The vertical stretching process is relatively complex, requiring precise control of parameters such as stretching speed, temperature, and cooling rate to ensure the uniformity and performance of the film.

Although uniaxial stretching is the main method, many production lines can also achieve biaxial stretching, usually by combining the above two methods to improve the performance of the film. Bi directional stretching can not only improve the tensile strength, transparency, and heat resistance of the film, but also achieve more uniform mechanical properties. This type of production line is receiving increasing attention because it can combine the advantages of horizontal and vertical stretching under certain conditions, providing higher quality films.

Author:admin