What is the difference between domestic and imported hollow board production lines

DATE:2024/10/21 10:44:14 / READ: / SOURCE:This station

There are significant differences between domestic and imported hollow board production lines in terms of technology, performance, price, after-sales service, and other aspects. These differences affect the decision-making of enterprises when choosing equipment, especially when considering factors such as production efficiency, product quality, and long-term investment returns.

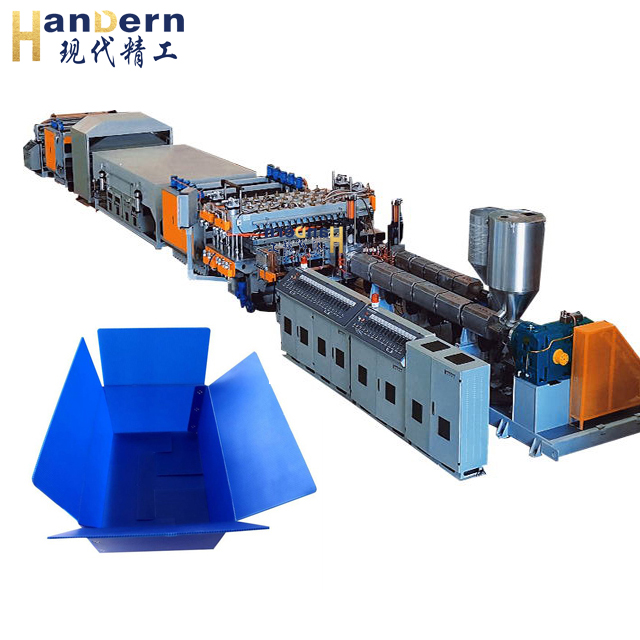

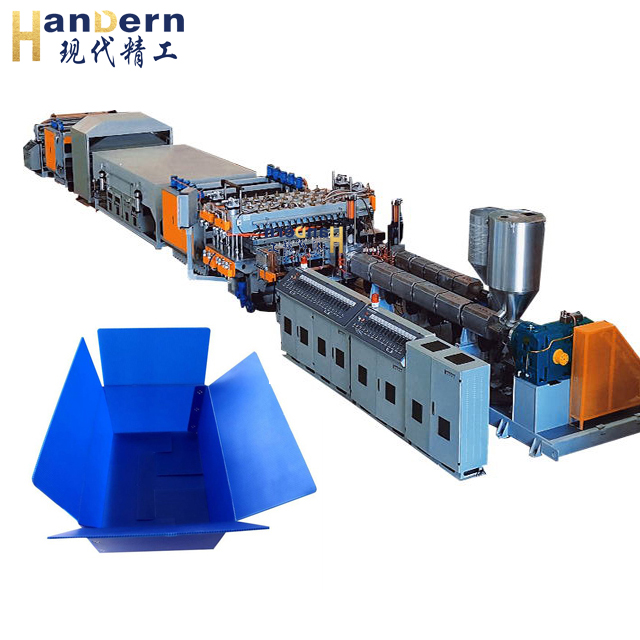

Firstly, one of the most significant differences is the level of technology and equipment performance. Imported hollow board production lines usually have strong advantages in technology research and innovation, with more advanced equipment design and more complete functions. Imported equipment often adopts more efficient extrusion systems, precision molds, and intelligent control systems, which can provide higher production efficiency and better product consistency. For example, the automation level of imported production lines is generally high, with more precise temperature control, pressure control, and speed regulation, making the production process more stable and reliable.

Firstly, one of the most significant differences is the level of technology and equipment performance. Imported hollow board production lines usually have strong advantages in technology research and innovation, with more advanced equipment design and more complete functions. Imported equipment often adopts more efficient extrusion systems, precision molds, and intelligent control systems, which can provide higher production efficiency and better product consistency. For example, the automation level of imported production lines is generally high, with more precise temperature control, pressure control, and speed regulation, making the production process more stable and reliable.

Secondly, material quality and manufacturing process are also important differences between domestic and imported production lines. Imported hollow board production lines usually have stricter material selection and processes, using higher quality components and materials, which can effectively reduce failure rates and extend equipment service life. Domestic production lines are also constantly improving in material selection and process control, but overall, there may be a gap in detail processing and process level compared to international high-end products. This makes the efficiency, production efficiency, and product quality of imported production lines superior to domestic equipment in some cases.

In terms of price, domestic hollow board production lines usually have a significant price advantage. Equipment with the same production capacity and configuration, domestically produced production lines are often more reasonably priced, which can reduce investment costs for small and medium-sized enterprises. This enables more enterprises to choose domestic equipment, especially in the context of China's emphasis on the development of local manufacturing industry, and many enterprises are willing to support local brands.

In terms of price, domestic hollow board production lines usually have a significant price advantage. Equipment with the same production capacity and configuration, domestically produced production lines are often more reasonably priced, which can reduce investment costs for small and medium-sized enterprises. This enables more enterprises to choose domestic equipment, especially in the context of China's emphasis on the development of local manufacturing industry, and many enterprises are willing to support local brands.

Furthermore, after-sales service and technical support are also important aspects. The after-sales service of imported equipment often relies on international suppliers, which may result in extended maintenance and parts replacement times, affecting the normal operation of the production line. Domestic equipment often provides faster local services and timely supply of accessories, reducing losses caused by equipment downtime. In addition, domestic equipment manufacturers usually have strong localization service capabilities, which can better understand customer needs and provide corresponding solutions according to the special situation of the enterprise.

Finally, there are differences in brand influence and market recognition. Some internationally renowned brands often have accumulated a good reputation in terms of technology and quality, and customers may be more inclined to choose products from these brands when making purchases. Relatively speaking, although domestic brands have a trend of continuous improvement, there is still room for improvement in market recognition and brand building.

Finally, there are differences in brand influence and market recognition. Some internationally renowned brands often have accumulated a good reputation in terms of technology and quality, and customers may be more inclined to choose products from these brands when making purchases. Relatively speaking, although domestic brands have a trend of continuous improvement, there is still room for improvement in market recognition and brand building.

In summary, there are significant differences between domestic and imported hollow board production lines in terms of technology, performance, price, after-sales service, etc. Among them, domestic hollow board production lines have higher cost-effectiveness. When choosing a production line, enterprises need to comprehensively consider their own production needs, budget, brand awareness, and the urgency of after-sales service, and make decisions that are suitable for their own development.

Secondly, material quality and manufacturing process are also important differences between domestic and imported production lines. Imported hollow board production lines usually have stricter material selection and processes, using higher quality components and materials, which can effectively reduce failure rates and extend equipment service life. Domestic production lines are also constantly improving in material selection and process control, but overall, there may be a gap in detail processing and process level compared to international high-end products. This makes the efficiency, production efficiency, and product quality of imported production lines superior to domestic equipment in some cases.

Furthermore, after-sales service and technical support are also important aspects. The after-sales service of imported equipment often relies on international suppliers, which may result in extended maintenance and parts replacement times, affecting the normal operation of the production line. Domestic equipment often provides faster local services and timely supply of accessories, reducing losses caused by equipment downtime. In addition, domestic equipment manufacturers usually have strong localization service capabilities, which can better understand customer needs and provide corresponding solutions according to the special situation of the enterprise.

In summary, there are significant differences between domestic and imported hollow board production lines in terms of technology, performance, price, after-sales service, etc. Among them, domestic hollow board production lines have higher cost-effectiveness. When choosing a production line, enterprises need to comprehensively consider their own production needs, budget, brand awareness, and the urgency of after-sales service, and make decisions that are suitable for their own development.

Author:admin