Can a hollow board production line simultaneously produce thin and thick plates

DATE:2024/10/19 10:00:30 / READ: / SOURCE:This station

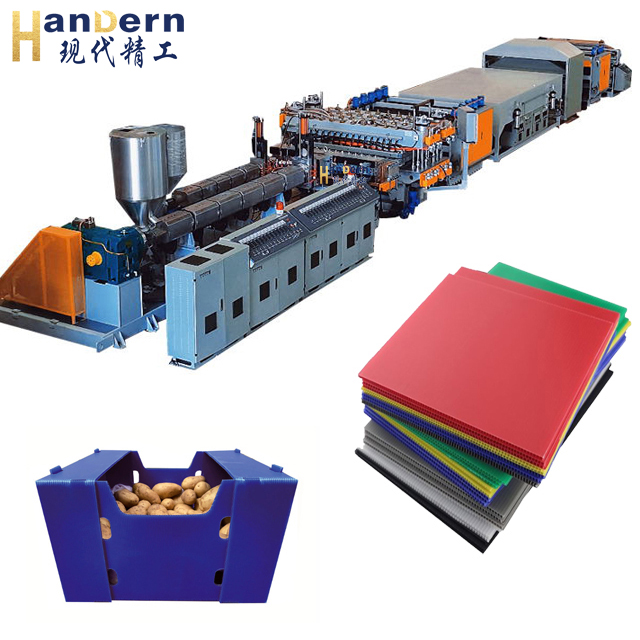

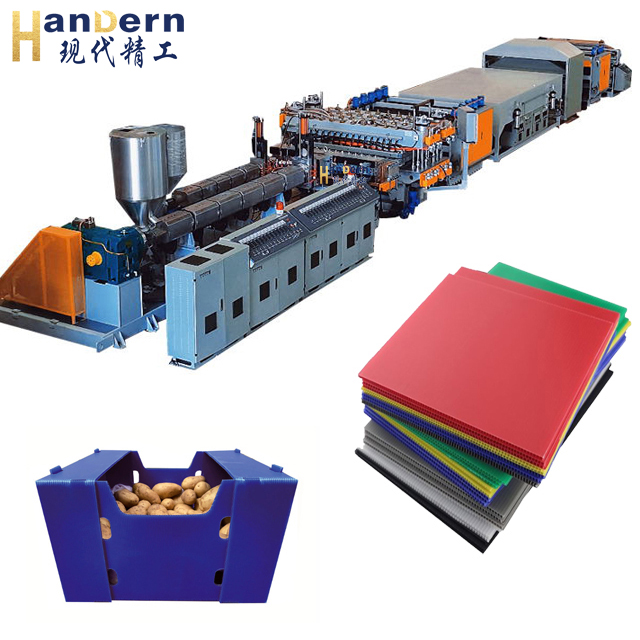

The design and configuration of the hollow board production line largely determine whether it can produce thin and thick plates simultaneously, and the main key points of design and configuration lie in the flexibility of the production line, mold design, extruder parameter settings, and operator technical experience.

Firstly, the flexibility of the equipment is a key factor determining whether the production line can produce hollow boards of different thicknesses. Modern hollow board production lines usually have high automation and flexibility, which can achieve a certain degree of production mode switching. This flexibility is not only reflected in the configuration of the molding machine, but also in the control system of each production process. Equipment with mold changing system and adjustment function can enable the production line to adapt to the requirements of different product thicknesses without prolonged downtime.

Firstly, the flexibility of the equipment is a key factor determining whether the production line can produce hollow boards of different thicknesses. Modern hollow board production lines usually have high automation and flexibility, which can achieve a certain degree of production mode switching. This flexibility is not only reflected in the configuration of the molding machine, but also in the control system of each production process. Equipment with mold changing system and adjustment function can enable the production line to adapt to the requirements of different product thicknesses without prolonged downtime.

Secondly, the design of the mold is crucial. In order to produce hollow boards of different thicknesses, the production line needs to have specially designed molds that can be easily and quickly switched while ensuring the quality of the finished product. Generally speaking, molds for thin plates have smaller flow channels and higher temperature requirements, while molds for thick plates require larger flow channels and relatively lower temperature control. Therefore, in actual production, in order to produce both thin and thick plates simultaneously, companies may need to prepare multiple sets of molds for rapid replacement in different production tasks.

In terms of extruder settings, users also need to consider the extrusion rate and viscosity of materials with different thicknesses. Thin plates typically require faster extrusion speeds while maintaining good fluidity, while thick plates require lower speeds to ensure sufficient melting and forming. In practical operation, if frequent switching between producing thin and thick plates is required, the operator needs to adjust the parameters such as extruder speed, temperature, and cooling rate according to the characteristics of the product to ensure proper material handling.

In terms of extruder settings, users also need to consider the extrusion rate and viscosity of materials with different thicknesses. Thin plates typically require faster extrusion speeds while maintaining good fluidity, while thick plates require lower speeds to ensure sufficient melting and forming. In practical operation, if frequent switching between producing thin and thick plates is required, the operator needs to adjust the parameters such as extruder speed, temperature, and cooling rate according to the characteristics of the product to ensure proper material handling.

In addition, the operator's technical experience is an important factor affecting production efficiency. Skilled operators can adjust various parameters in a timely manner according to the requirements of materials and products, ensuring the smooth process of producing products of different thicknesses simultaneously. They need to have rich knowledge of material properties and a deep understanding of equipment and molds in order to respond quickly when changing production tasks.

Finally, although modern production lines can technically achieve the ability to produce both thin and thick plates simultaneously, in specific production environments, factors such as market demand, production efficiency, and economic benefits need to be comprehensively considered. If production orders frequently change, it is recommended that companies conduct market research to evaluate whether to invest in and maintain a production line that can support multiple specifications of products to ensure effective resource utilization.

Finally, although modern production lines can technically achieve the ability to produce both thin and thick plates simultaneously, in specific production environments, factors such as market demand, production efficiency, and economic benefits need to be comprehensively considered. If production orders frequently change, it is recommended that companies conduct market research to evaluate whether to invest in and maintain a production line that can support multiple specifications of products to ensure effective resource utilization.

Overall, in order to enable the hollow board production line to simultaneously produce thin and thick plates, sufficient preparation and coordination are required in equipment configuration, mold design, extruder setup, and operator skills.

Secondly, the design of the mold is crucial. In order to produce hollow boards of different thicknesses, the production line needs to have specially designed molds that can be easily and quickly switched while ensuring the quality of the finished product. Generally speaking, molds for thin plates have smaller flow channels and higher temperature requirements, while molds for thick plates require larger flow channels and relatively lower temperature control. Therefore, in actual production, in order to produce both thin and thick plates simultaneously, companies may need to prepare multiple sets of molds for rapid replacement in different production tasks.

In addition, the operator's technical experience is an important factor affecting production efficiency. Skilled operators can adjust various parameters in a timely manner according to the requirements of materials and products, ensuring the smooth process of producing products of different thicknesses simultaneously. They need to have rich knowledge of material properties and a deep understanding of equipment and molds in order to respond quickly when changing production tasks.

Overall, in order to enable the hollow board production line to simultaneously produce thin and thick plates, sufficient preparation and coordination are required in equipment configuration, mold design, extruder setup, and operator skills.

Author:admin