What is the difference between a cast film production line and a laminating machine

DATE:2024/10/17 10:10:59 / READ: / SOURCE:This station

Casting film production line and laminating machine are two common types of film production equipment, which produce very similar films. However, they differ in terms of equipment structure, production process, final product performance, and application fields. Below, we will briefly introduce these two types of equipment.

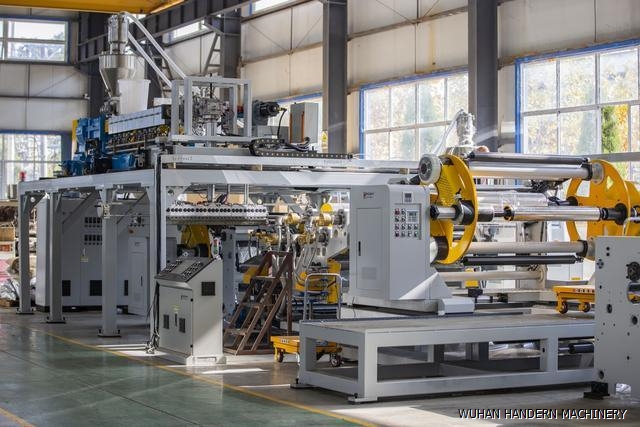

Cast film production line: mainly used for producing polymer films, usually using polyethylene (PE), polypropylene (PP) and other raw materials. This production line processes plastic particles into continuous films through heating and extrusion, and the thickness and width of the films can be adjusted according to process parameters. Cast film is widely used in packaging, printing, protective film and other fields.

Film laminating machine: It is a mechanical equipment specifically used for laminating films with paper or other substrates. The laminating machine applies hot melt adhesive or water-based glue to the surface of the substrate, and then adheres the film to the substrate through coating or hot pressing. This process is commonly used in food packaging, industrial packaging, and the processing of some special paper products.

2. Technological process

Production process of cast film:

Raw material preparation: Plastic particles are dried and then fed into the extruder.

Extrusion and die: After the plastic melts in the extruder, it is extruded through the die to form a film like material.

Cooling and shaping: The film is cooled and shaped on a cooling roller.

Traction and winding: The finalized film is pulled by the traction device to the cutting machine and finally wound up.

Film lamination process:

Substrate preparation: Paper or other substrates are placed in the feeding device.

Glue coating: Apply glue evenly on the surface of the substrate through a glue coating device.

Composite: The film is heated and pressed onto a substrate coated with adhesive.

Cooling and cutting: After the composite is completed, the substrate and film are shaped through a cooling system before cutting and winding.

3. Application Fields

The thin film of the casting film production line is mainly used for:

Packaging industry (food packaging, electronic product packaging, etc.)

Printing industry

Industrial use (in the fields of protective films, electronic products, etc.)

The laminating machine is more commonly used for:

Food packaging (such as laminated paper bags, beverage packaging)

Consumer goods for daily life (such as facial tissues, toilet paper, etc.)

Industrial products (such as packaging boxes, labels, etc.)

4. Equipment structure and complexity

The structure of a cast film production line is usually complex, involving multiple links such as extruders, die heads, cooling rollers, traction devices, and cutting machines. The entire production process is continuous and highly automated.

The laminating machine is relatively simple, mainly composed of a feeding device, a coating device, a laminating device, a cooling and cutting system, and is relatively easy to operate and maintain.

5. Production efficiency and flexibility

Due to the characteristics and requirements of the product, the cast film production line generally requires significant investment and long-term debugging, but once it runs stably, the production capacity is relatively high.

The laminating machine has high flexibility and fast mold changing ability, and can quickly switch between different types of substrates and films.

Cast film production line: mainly used for producing polymer films, usually using polyethylene (PE), polypropylene (PP) and other raw materials. This production line processes plastic particles into continuous films through heating and extrusion, and the thickness and width of the films can be adjusted according to process parameters. Cast film is widely used in packaging, printing, protective film and other fields.

Film laminating machine: It is a mechanical equipment specifically used for laminating films with paper or other substrates. The laminating machine applies hot melt adhesive or water-based glue to the surface of the substrate, and then adheres the film to the substrate through coating or hot pressing. This process is commonly used in food packaging, industrial packaging, and the processing of some special paper products.

2. Technological process

Production process of cast film:

Raw material preparation: Plastic particles are dried and then fed into the extruder.

Extrusion and die: After the plastic melts in the extruder, it is extruded through the die to form a film like material.

Cooling and shaping: The film is cooled and shaped on a cooling roller.

Traction and winding: The finalized film is pulled by the traction device to the cutting machine and finally wound up.

Film lamination process:

Substrate preparation: Paper or other substrates are placed in the feeding device.

Glue coating: Apply glue evenly on the surface of the substrate through a glue coating device.

Composite: The film is heated and pressed onto a substrate coated with adhesive.

Cooling and cutting: After the composite is completed, the substrate and film are shaped through a cooling system before cutting and winding.

3. Application Fields

The thin film of the casting film production line is mainly used for:

Packaging industry (food packaging, electronic product packaging, etc.)

Printing industry

Industrial use (in the fields of protective films, electronic products, etc.)

The laminating machine is more commonly used for:

Food packaging (such as laminated paper bags, beverage packaging)

Consumer goods for daily life (such as facial tissues, toilet paper, etc.)

Industrial products (such as packaging boxes, labels, etc.)

4. Equipment structure and complexity

The structure of a cast film production line is usually complex, involving multiple links such as extruders, die heads, cooling rollers, traction devices, and cutting machines. The entire production process is continuous and highly automated.

The laminating machine is relatively simple, mainly composed of a feeding device, a coating device, a laminating device, a cooling and cutting system, and is relatively easy to operate and maintain.

5. Production efficiency and flexibility

Due to the characteristics and requirements of the product, the cast film production line generally requires significant investment and long-term debugging, but once it runs stably, the production capacity is relatively high.

The laminating machine has high flexibility and fast mold changing ability, and can quickly switch between different types of substrates and films.

Author:admin