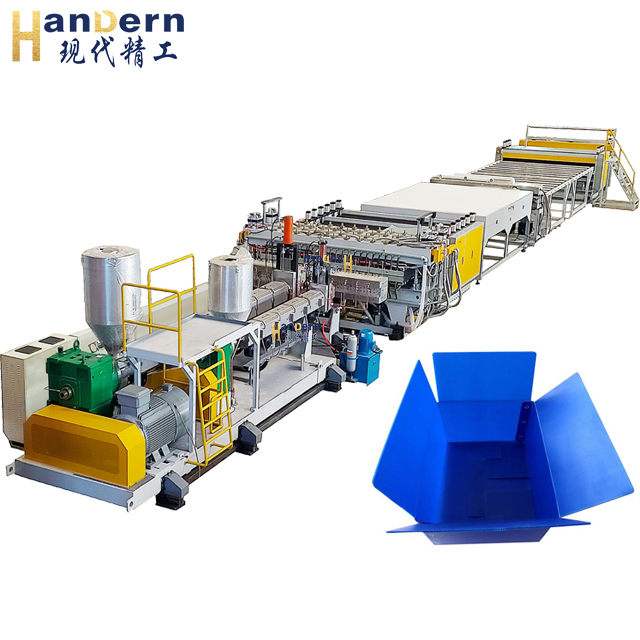

Have you maintained these parts of the PP hollow board production line

DATE:2024/9/27 11:38:31 / READ: / SOURCE:This station

The various components of the PP hollow board production line play a very important role in the operation process. Once this production equipment is turned on, it needs to operate continuously for a long time. Faced with this high-intensity production, if these components are not properly maintained, various failures may occur. Therefore, proper maintenance is particularly important. So what are the key maintenance points for the PP hollow board production line, and how should these areas be maintained?

1. Extruder

1. Extruder

The extruder is one of the core equipment for producing PP hollow boards. The maintenance of the extruder should focus on the following aspects:

Screw and cylinder: Screw and cylinder are the main components for material plasticization and mixing. Regularly check its wear and maintain a smooth surface. After prolonged work, it should be cleaned and inspected to prevent uneven plasticization caused by abnormal wear and tear.

Heating coil and temperature control system: The heating coil needs to be regularly checked for its heating performance to ensure that the temperature control system is working properly and to avoid the impact of high or low temperature on the material.

2. Mold

Mold is crucial for the appearance and dimensional accuracy of finished products, and maintenance work includes:

Cleaning: After each batch of production is completed, the molds should be cleaned in a timely manner to prevent secondary pollution caused by material residue, and attention should be paid to the use of cleaning agents to avoid damaging the surface of the molds.

Maintenance and adjustment: Regularly check the fitting accuracy and surface condition of the mold, and repair or replace it if necessary to ensure good molding effect for a long time.

3. Cooling system

3. Cooling system

The cooling system plays a decisive role in the hollow board forming process, and maintenance focuses include:

Water pipes and cooling devices: Regularly check the flow rate and temperature of the cooling water, keep the waterway unobstructed, prevent blockage and leakage, and ensure the cooling effect.

Cooling tank: Regularly remove dirt and impurities from the tank to maintain clean water quality, while checking the sealing of the cooling tank to prevent water leakage.

4. Traction device

The traction device is used to control the stretching of the board. During maintenance, attention should be paid to:

Belt and Chain: Check whether the belt or chain of the traction device is worn or loose, adjust and replace it regularly to ensure stable transmission and not affect production speed and product quality.

Motor and transmission device: Regularly check the operation of the motor and the lubrication status of the transmission device, and supplement and replace lubricating grease if necessary to ensure the normal operation of the drive system.

5. Cutting device and winding device

5. Cutting device and winding device

Cutting and winding are important links that affect the quality of the final product, and key maintenance items include:

Knife: Regularly check the sharpness of the knife and sharpen or replace it if necessary.

Roll up: Check if the roll up is balanced and clean regularly to prevent dirt from affecting the smoothness of winding.

6. Electronic Control System

The electronic control system is an important part of the intelligent production line, and special attention should be paid to:

Lines and connectors: Regularly check the insulation of the lines and the tightness of the connectors to ensure that there are no looseness, leakage, or other phenomena.

Control panel: Regularly clean the control panel to ensure accurate operation and display.

The extruder is one of the core equipment for producing PP hollow boards. The maintenance of the extruder should focus on the following aspects:

Screw and cylinder: Screw and cylinder are the main components for material plasticization and mixing. Regularly check its wear and maintain a smooth surface. After prolonged work, it should be cleaned and inspected to prevent uneven plasticization caused by abnormal wear and tear.

Heating coil and temperature control system: The heating coil needs to be regularly checked for its heating performance to ensure that the temperature control system is working properly and to avoid the impact of high or low temperature on the material.

2. Mold

Mold is crucial for the appearance and dimensional accuracy of finished products, and maintenance work includes:

Cleaning: After each batch of production is completed, the molds should be cleaned in a timely manner to prevent secondary pollution caused by material residue, and attention should be paid to the use of cleaning agents to avoid damaging the surface of the molds.

Maintenance and adjustment: Regularly check the fitting accuracy and surface condition of the mold, and repair or replace it if necessary to ensure good molding effect for a long time.

The cooling system plays a decisive role in the hollow board forming process, and maintenance focuses include:

Water pipes and cooling devices: Regularly check the flow rate and temperature of the cooling water, keep the waterway unobstructed, prevent blockage and leakage, and ensure the cooling effect.

Cooling tank: Regularly remove dirt and impurities from the tank to maintain clean water quality, while checking the sealing of the cooling tank to prevent water leakage.

4. Traction device

The traction device is used to control the stretching of the board. During maintenance, attention should be paid to:

Belt and Chain: Check whether the belt or chain of the traction device is worn or loose, adjust and replace it regularly to ensure stable transmission and not affect production speed and product quality.

Motor and transmission device: Regularly check the operation of the motor and the lubrication status of the transmission device, and supplement and replace lubricating grease if necessary to ensure the normal operation of the drive system.

Cutting and winding are important links that affect the quality of the final product, and key maintenance items include:

Knife: Regularly check the sharpness of the knife and sharpen or replace it if necessary.

Roll up: Check if the roll up is balanced and clean regularly to prevent dirt from affecting the smoothness of winding.

6. Electronic Control System

The electronic control system is an important part of the intelligent production line, and special attention should be paid to:

Lines and connectors: Regularly check the insulation of the lines and the tightness of the connectors to ensure that there are no looseness, leakage, or other phenomena.

Control panel: Regularly clean the control panel to ensure accurate operation and display.

Author:admin