What is a wet process lithium battery separator production line

DATE:2024/9/4 14:17:13 / READ: / SOURCE:This station

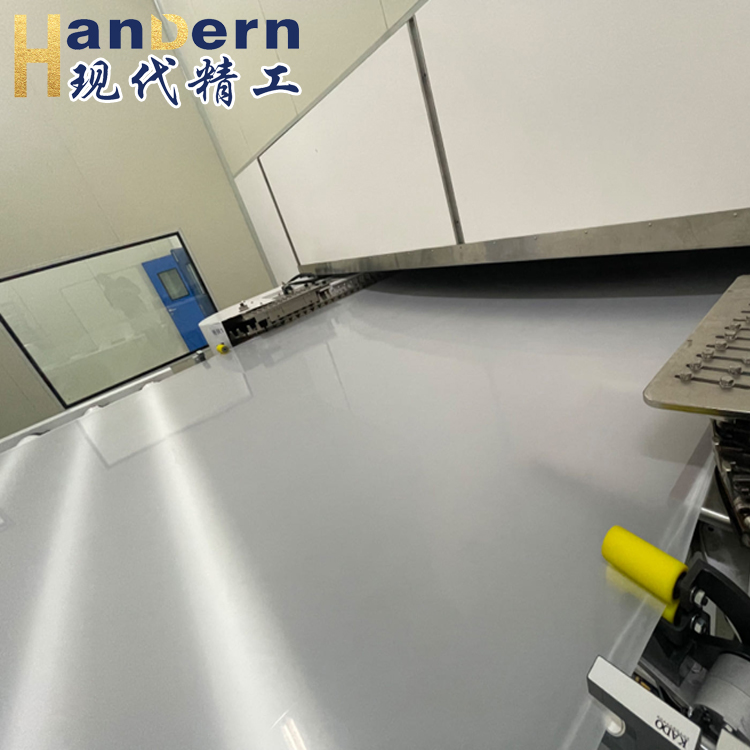

The process of wet membrane production line usually involves dissolving polymers (such as polyethylene oxide (PEO)) in a solvent to form a sol, then coating it onto a supporting substrate through a coating process, and finally forming a film through solvent evaporation, drying, and stretching treatment.

Dissolve and mix: Mix the polymer with a solvent to form a uniform adhesive solution.

Coating: Use a coating machine to evenly apply the adhesive solution onto the substrate (such as polyester film).

Drying: Remove solvents through methods such as hot air or vacuum drying to form a solid film.

Stretching: After drying, the film is subjected to longitudinal and transverse stretching treatment to enhance its performance.

Characteristics of Wet Diaphragm Production Line

The porosity and nanostructure of the membrane are controllable: Wet process technology allows for obtaining different porosity and membrane structures through different solution formulations and coating processes, adapting to different battery requirements.Superior membrane performance: Typically, wet process produced membranes exhibit excellent electrolyte wettability, ion conductivity, and thermal stability.

Solvent usage: This process requires the use of solvents, which may have potential environmental impacts and safety issues that need to be considered.

Application of Wet Diaphragm Production Line

Wet process separators are mainly used in high-performance lithium batteries, energy storage batteries, and some batteries with specific needs, to meet the requirements of high-power and high-energy density batteries.Author:admin