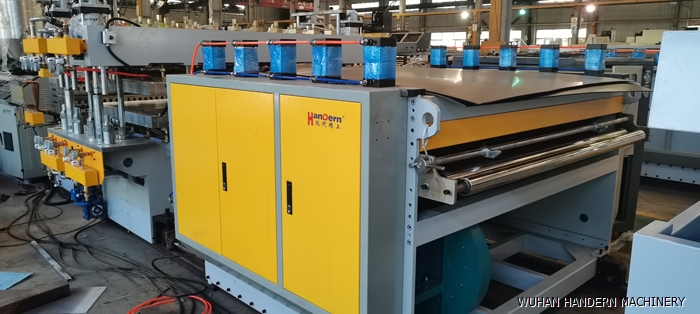

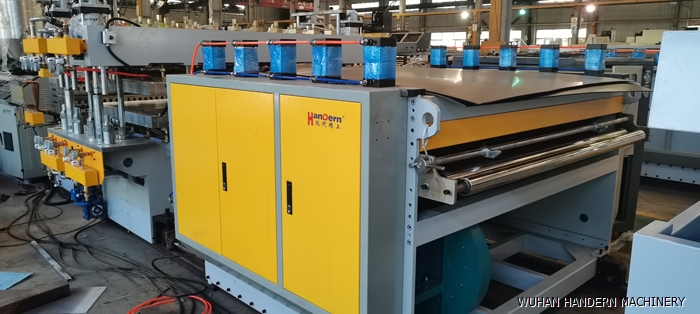

How to set the operating temperature of the plastic hollow board extrusion equipment correctly

DATE:2024/7/6 11:05:08 / READ: / SOURCE:This station

When setting the operating temperature of the plastic hollow board extrusion equipment, decisions should be made based on the type of plastic raw materials used and the specific process requirements. At present, the raw materials suitable for hollow board extrusion equipment mainly include PP polypropylene, PC polycarbonate, and PE polyethylene. When setting the operating temperature of plastic hollow board extrusion equipment, it is necessary to exceed the melting temperature of these plastic raw materials to ensure that plastic particles can be fully melted and extruded smoothly. At the same time, it is also necessary to consider the thermal stability of plastics and avoid excessive temperatures that may cause plastic decomposition or oxidation, which may affect product quality.

The three common plastic raw materials mentioned above have melting temperatures between 120C and 220C, respectively. Therefore, generally speaking, the operating temperature range of plastic hollow board extrusion equipment is roughly within this range. The specific operating temperature needs to be determined based on the production process requirements and the characteristics of plastic raw materials.

The three common plastic raw materials mentioned above have melting temperatures between 120C and 220C, respectively. Therefore, generally speaking, the operating temperature range of plastic hollow board extrusion equipment is roughly within this range. The specific operating temperature needs to be determined based on the production process requirements and the characteristics of plastic raw materials.

Additionally, it should be noted that during the production process, operators not only need to set the temperature based on the specific type of plastic material, but also need to consider factors such as product requirements and equipment performance to set an appropriate extrusion temperature. Normally, operators adjust the heating temperature and extrusion speed of the extruder based on production experience and process requirements to ensure that plastic particles can fully melt, flow smoothly, and fill the mold completely, ultimately producing plastic hollow board products that meet the requirements.

Additionally, it should be noted that during the production process, operators not only need to set the temperature based on the specific type of plastic material, but also need to consider factors such as product requirements and equipment performance to set an appropriate extrusion temperature. Normally, operators adjust the heating temperature and extrusion speed of the extruder based on production experience and process requirements to ensure that plastic particles can fully melt, flow smoothly, and fill the mold completely, ultimately producing plastic hollow board products that meet the requirements.

Finally, it is important to constantly monitor and adjust the operating temperature of the extrusion equipment during the production process to maintain a stable production state and ensure product quality and efficiency. By reasonably controlling and adjusting the operating temperature of the extrusion equipment, efficient production, energy conservation, and ensuring product quality and stability can be achieved.

Finally, it is important to constantly monitor and adjust the operating temperature of the extrusion equipment during the production process to maintain a stable production state and ensure product quality and efficiency. By reasonably controlling and adjusting the operating temperature of the extrusion equipment, efficient production, energy conservation, and ensuring product quality and stability can be achieved.

Author:admin