What are the differences between PP plastic hollow panels and other plastic panels

DATE:2023/6/7 14:14:32 / READ: / SOURCE:This station

PP plastic hollow board is a widely used plastic board. What are the differences between it and other types of plastic boards? Today, the editor will give you a brief answer to this question.

1、 Different structures

1、 Different structures

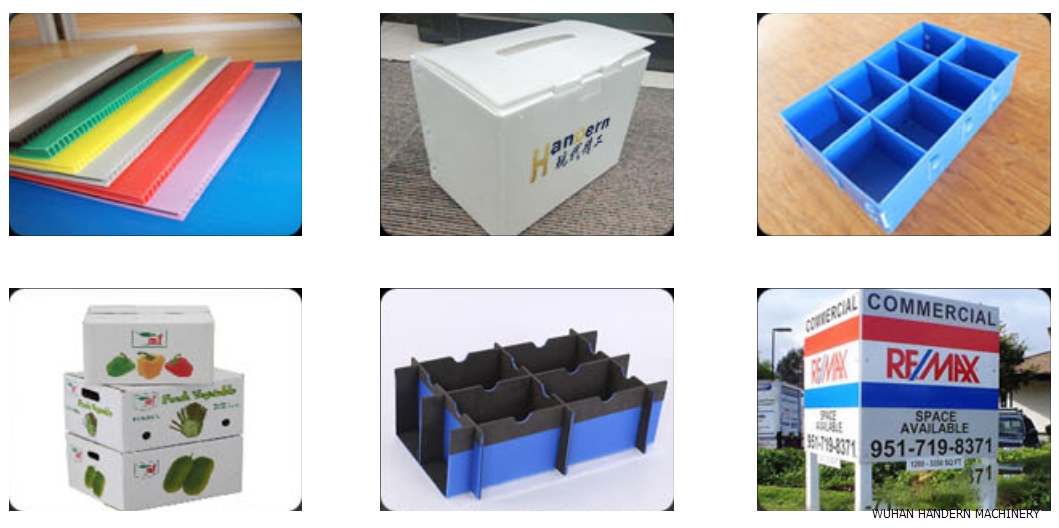

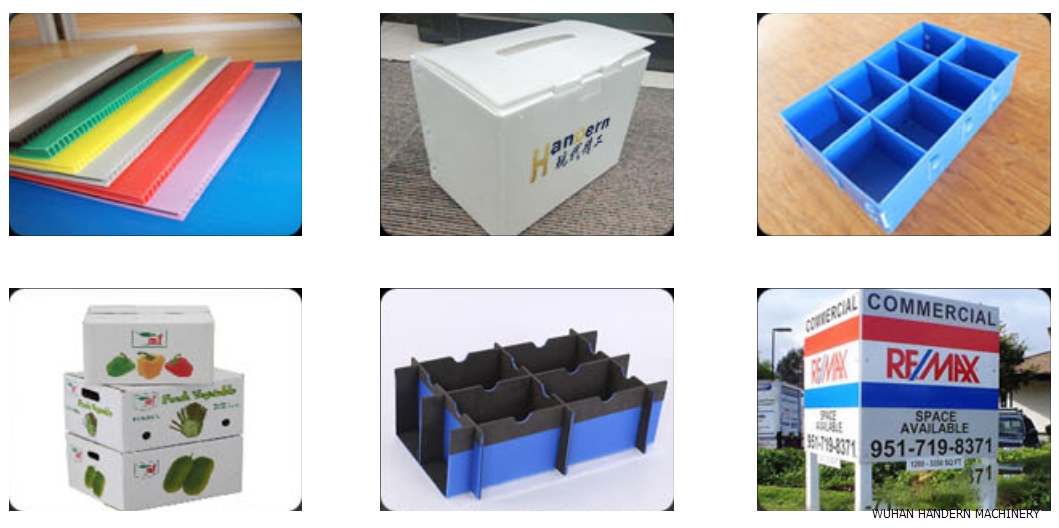

The biggest difference between PP plastic hollow panels and other plastic panels lies in their different structures. PP plastic hollow board is composed of a series of hollow cavities between two flat boards, which can be square, hexagonal, or other shapes. This structure makes the hollow board lighter and more sturdy because it can better resist bending and twisting. Other plastic boards are single solid boards without hollow structures.

2、 Different performance

The performance of PP plastic hollow panels is also different from other plastic panels. The hollow plate has better heat insulation performance and noise absorption performance, because the middle cavity can block heat conduction and sound wave propagation. This has made hollow panels widely used in fields such as construction, packaging, and advertising. In addition, hollow boards also have better waterproof and weather resistance, making them suitable for long-term use in outdoor environments.

The performance of other plastic panels varies depending on their materials and processing methods. For example, hard PVC panels have high strength and stiffness, making them suitable for making building materials and furniture. Soft PVC boards have good flexibility and corrosion resistance, making them suitable for making products such as oilcloth and raincoats. In addition, other plastic panels also have special properties such as UV resistance, anti-static, and fire resistance, which can be selected according to different application needs.

3、 Different processing methods

The processing methods of PP plastic hollow board and other plastic boards are also different. Hollow boards usually use extrusion molding technology, where the plastic is melted first and then extruded into shape through a mold. Due to the complex structure of hollow plates, special extruders and molds are required during the production process to ensure quality. Other plastic panels can be processed using various processes such as extrusion, rolling, and injection molding, and selected according to different material and product requirements.

4、 Different uses

4、 Different uses

The purpose of PP plastic hollow board and other plastic boards is also different. Hollow boards are commonly used in fields such as construction, packaging, and advertising. For example, hollow boards can be used to make building materials such as partitions, roofs, and ceilings, as well as to make products such as packaging boxes, display boards, and billboards. Other plastic panels can be used to make different products such as furniture, electronic products, and automotive components.

Overall, PP plastic hollow panels and other plastic panels are two common types of plastic products. Their structure, performance, processing methods, and uses are all different. When selecting materials and products, it is necessary to make choices based on actual needs and choose products that are suitable for oneself.

The biggest difference between PP plastic hollow panels and other plastic panels lies in their different structures. PP plastic hollow board is composed of a series of hollow cavities between two flat boards, which can be square, hexagonal, or other shapes. This structure makes the hollow board lighter and more sturdy because it can better resist bending and twisting. Other plastic boards are single solid boards without hollow structures.

2、 Different performance

The performance of PP plastic hollow panels is also different from other plastic panels. The hollow plate has better heat insulation performance and noise absorption performance, because the middle cavity can block heat conduction and sound wave propagation. This has made hollow panels widely used in fields such as construction, packaging, and advertising. In addition, hollow boards also have better waterproof and weather resistance, making them suitable for long-term use in outdoor environments.

The performance of other plastic panels varies depending on their materials and processing methods. For example, hard PVC panels have high strength and stiffness, making them suitable for making building materials and furniture. Soft PVC boards have good flexibility and corrosion resistance, making them suitable for making products such as oilcloth and raincoats. In addition, other plastic panels also have special properties such as UV resistance, anti-static, and fire resistance, which can be selected according to different application needs.

3、 Different processing methods

The processing methods of PP plastic hollow board and other plastic boards are also different. Hollow boards usually use extrusion molding technology, where the plastic is melted first and then extruded into shape through a mold. Due to the complex structure of hollow plates, special extruders and molds are required during the production process to ensure quality. Other plastic panels can be processed using various processes such as extrusion, rolling, and injection molding, and selected according to different material and product requirements.

The purpose of PP plastic hollow board and other plastic boards is also different. Hollow boards are commonly used in fields such as construction, packaging, and advertising. For example, hollow boards can be used to make building materials such as partitions, roofs, and ceilings, as well as to make products such as packaging boxes, display boards, and billboards. Other plastic panels can be used to make different products such as furniture, electronic products, and automotive components.

Overall, PP plastic hollow panels and other plastic panels are two common types of plastic products. Their structure, performance, processing methods, and uses are all different. When selecting materials and products, it is necessary to make choices based on actual needs and choose products that are suitable for oneself.

Author:admin