Hollow Sheet Production Line

DATE:2025/3/26 15:37:33 / READ: / SOURCE:This station

Hollow Sheet Production Line

Today, I'm going to show you a video of the trial run of the Hollow Sheet Production Line before it's shipped. The Hollow Sheet Production Line is widely applied in industries such as the luggage and bag industry, the hardware industry, the warehousing industry, the manufacturing of backing plates and cans, the auto parts industry, and the advertising industry, etc. It has the characteristics of being waterproof and moisture-proof, shockproof and compression-resistant, and it also features low cost and light weight. The Hollow Sheet Production Line can be customized to have a wider width.

Hollow Sheet Production Line With 1100 lines all around the world

Hollow Sheet Production Line can be classified differently according to the thickness, width, structure, shape of the products they produce, as well as the types of plastic raw materials used:

- According to the product width, they can be divided into units with widths of 1400mm, 1800mm, 2300mm, 2400mm, 2600mm, 2800mm, 3000mm, and 3200mm.

- According to the product thickness, they can be divided into units for thickness ranges of 2 - 6mm, 6 - 12mm, and 12 - 18mm.

- According to the product structure, they can be divided into double - wall sheets, triple - wall sheets, and quadruple - wall sheets.

- According to the product shape, they can be divided into ordinary type - I, type - S, type - V, type - X, and rice - shaped.

- According to the plastic raw materials used for the products, they can be divided into those using PP, PE, and PC.

- In addition, there are various product series such as ultra - light and ultra - thin sheets, and hollow films for greenhouse.

Hollow Sheet Production Line

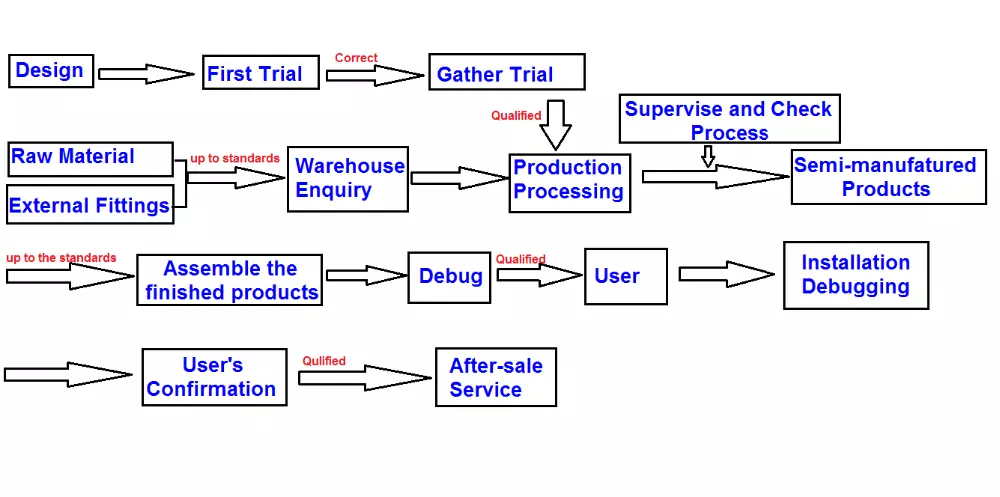

Quality control:strict and careful production and check

Technical Parameter

| Machine type | Sheet width(mm) | Sheet thickness(mm) | Max.Extrusion capacity(KG/H) |

|---|---|---|---|

| 1400 | 1250 | 2-6 6-12 12-18 | 280/280/350 |

| 1800 | 1650 | 2-6 6-12 12-18 | 320/350/420 |

| 2300 | 2150 | 2-6 6-12 | 350/350 |

| 2400 | 2200 | 2-6 6-12 | 450 |

| 2600 | 2450 | 2-6 6-12 | 480 |

| 2800 | 2600 | 2-6 6-12 | 500 |

| Hollow Sheet Production Line | Unit |

|---|---|

| Single Screw Extruder | one set |

| Die | one set |

| Hydraulic Pressure Screen Changer | one set |

| Vaccum Calibration Table | one set |

| First Haul-off | one set |

| Oven | one set |

| Cooling Device | one set |

| Second haul-off | one set |

| Cutting device | one set |

| Electrical Control Cabinet | one set |

| Stacker | one set |

| Screw Loader | one set |

Hollow Sheet Production Line 7 Advantages

- Good mechanic property:The special structure from plastic hollow board provides good reflexibility, anti-shock, high anti-pressure strength, higher hardness, good bent feature and shock buffer.

- Light weight and material reduction: Under the same effect, it can make plastic hollow board with material consumption reduction, costing lower and light weight.

- Heat perservation and sound proof:Hollow board’s hollow structure make it's heat and sound transfering effect abviously lower than solid board, reaching good heat perservation and soundproof effect.

- Anti-static, electricity conduction and fire resistant:Adopting changed property, mixed, surface spread, etc, makes plastic hollow board with the property of anti-static electricity,electricity conduction and fire resistant.

- Stable chemical property:Plastic hollow board can be water proof, damp proof, anti-erosion, compared with board free of fumigation, it has obvious advantage.

- Smoothy surface, good looking apperance and complete color variety:With special forming manufacturing process and adjusting color-master’s material, it can reach random color, and the surface is smoothy, printing is easy.

- Good enviroment-protection effect:Plastic hollow board has the features of non-toxic, free of polution, easy to handle, so it avoids polution, also can be re-used or being done to other plastic finished product

Author:admin