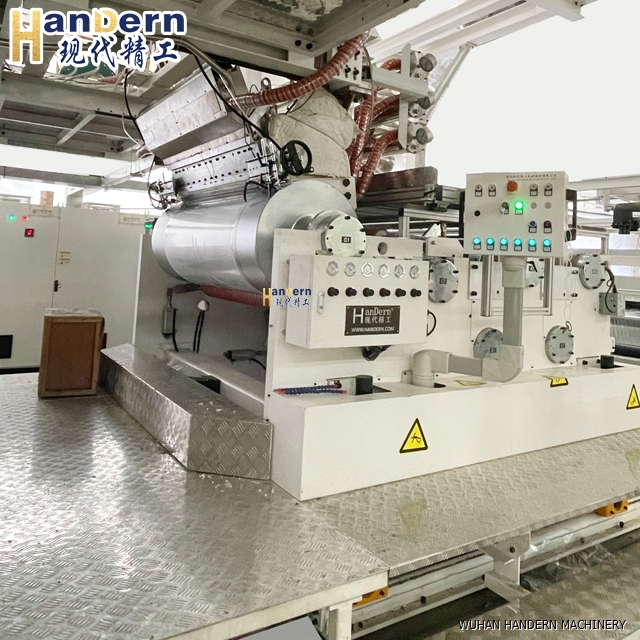

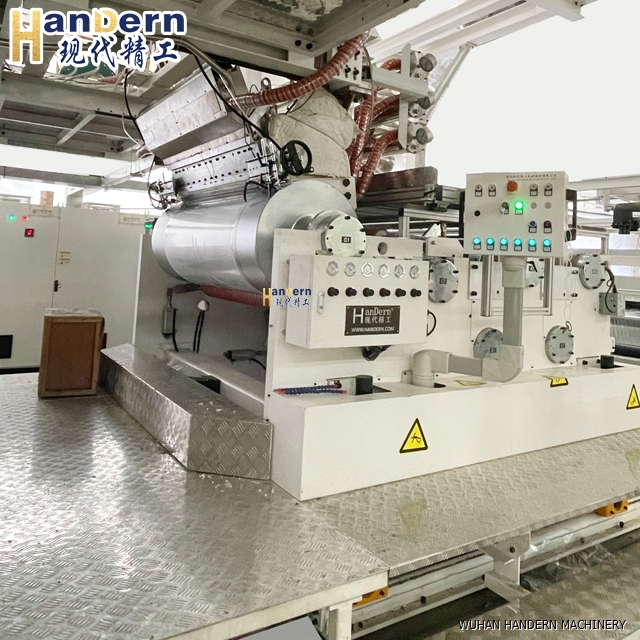

How to allocate personnel for the dry process lithium battery separator production line

DATE:2024/11/29 10:11:08 / READ: / SOURCE:This station

Reasonable personnel allocation is an important factor in ensuring production efficiency, product quality, and safety in the dry process lithium battery separator production line. With the rapid development of the lithium battery market, enterprises need to fully consider the professional skills and job requirements of each link in personnel allocation. The following are detailed recommendations for staffing the dry process lithium battery separator production line.

1. Analysis of Production Line Positions

1. Analysis of Production Line Positions

Firstly, conduct a job analysis on the production line to clarify the responsibilities and requirements of each position. The main processes of the dry process lithium battery separator production line include material preparation, coating, drying, cutting, inspection, and packaging. Each stage requires the deployment of different professionals:

Material Preparation Personnel: Responsible for receiving, storing, and preparing raw materials, requiring a certain level of chemical knowledge and material management experience.

Production operator: mainly responsible for the operation and maintenance of equipment. Strong mechanical operation skills are required, as well as the ability to identify and handle common equipment malfunctions.

Quality control personnel: responsible for product quality testing and monitoring to ensure that products meet standards. This position requires a certain level of professional knowledge in chemical analysis and material testing.

Maintenance technicians: responsible for the daily maintenance and troubleshooting of equipment, requiring a background in mechanical, electrical, and automation related fields.

2. Determine the number of personnel

2. Determine the number of personnel

The allocation of personnel should be determined based on the scale and production capacity requirements of the production line. Typically, a standard dry process lithium battery separator production line may require the following personnel configuration:

Material preparation: 1-2 people

Production operators: 2-4 people (depending on the number of equipment)

Quality inspectors: 1-2 people

Maintenance technician: 1 person (can be added according to equipment maintenance needs)

Supervisor or team leader: 1 person (responsible for overall production management and coordination)

3. Personnel training and skill enhancement

In order to ensure that personnel are capable of fulfilling their respective job responsibilities, it is necessary to provide systematic training to employees. Employee training should include:

Operation training: Ensure that production operators are proficient in the operating procedures and safety procedures of the equipment.

Quality management training: Provide professional quality management and testing technology training to quality inspection personnel to improve their inspection ability and sensitivity to discovering problems.

Equipment maintenance training: Provide professional training for maintenance personnel on equipment maintenance and troubleshooting to enhance their ability to handle unexpected situations.

The personnel configuration of the dry process lithium battery separator production line is a complex system engineering, involving multiple aspects such as job analysis, personnel quantity, training, standardized processes, team cooperation, and safety management. By rational allocation of human resources, production efficiency can be improved, product quality can be guaranteed, and strong guarantees can be provided for safety production. With the continuous development of technology and market, enterprises should regularly evaluate and adjust personnel configuration to adapt to business changes and development needs.

The personnel configuration of the dry process lithium battery separator production line is a complex system engineering, involving multiple aspects such as job analysis, personnel quantity, training, standardized processes, team cooperation, and safety management. By rational allocation of human resources, production efficiency can be improved, product quality can be guaranteed, and strong guarantees can be provided for safety production. With the continuous development of technology and market, enterprises should regularly evaluate and adjust personnel configuration to adapt to business changes and development needs.

Firstly, conduct a job analysis on the production line to clarify the responsibilities and requirements of each position. The main processes of the dry process lithium battery separator production line include material preparation, coating, drying, cutting, inspection, and packaging. Each stage requires the deployment of different professionals:

Material Preparation Personnel: Responsible for receiving, storing, and preparing raw materials, requiring a certain level of chemical knowledge and material management experience.

Production operator: mainly responsible for the operation and maintenance of equipment. Strong mechanical operation skills are required, as well as the ability to identify and handle common equipment malfunctions.

Quality control personnel: responsible for product quality testing and monitoring to ensure that products meet standards. This position requires a certain level of professional knowledge in chemical analysis and material testing.

Maintenance technicians: responsible for the daily maintenance and troubleshooting of equipment, requiring a background in mechanical, electrical, and automation related fields.

The allocation of personnel should be determined based on the scale and production capacity requirements of the production line. Typically, a standard dry process lithium battery separator production line may require the following personnel configuration:

Material preparation: 1-2 people

Production operators: 2-4 people (depending on the number of equipment)

Quality inspectors: 1-2 people

Maintenance technician: 1 person (can be added according to equipment maintenance needs)

Supervisor or team leader: 1 person (responsible for overall production management and coordination)

3. Personnel training and skill enhancement

In order to ensure that personnel are capable of fulfilling their respective job responsibilities, it is necessary to provide systematic training to employees. Employee training should include:

Operation training: Ensure that production operators are proficient in the operating procedures and safety procedures of the equipment.

Quality management training: Provide professional quality management and testing technology training to quality inspection personnel to improve their inspection ability and sensitivity to discovering problems.

Equipment maintenance training: Provide professional training for maintenance personnel on equipment maintenance and troubleshooting to enhance their ability to handle unexpected situations.

Author:admin