How to conduct acceptance work on PP hollow board equipment

DATE:2024/9/24 14:24:58 / READ: / SOURCE:This station

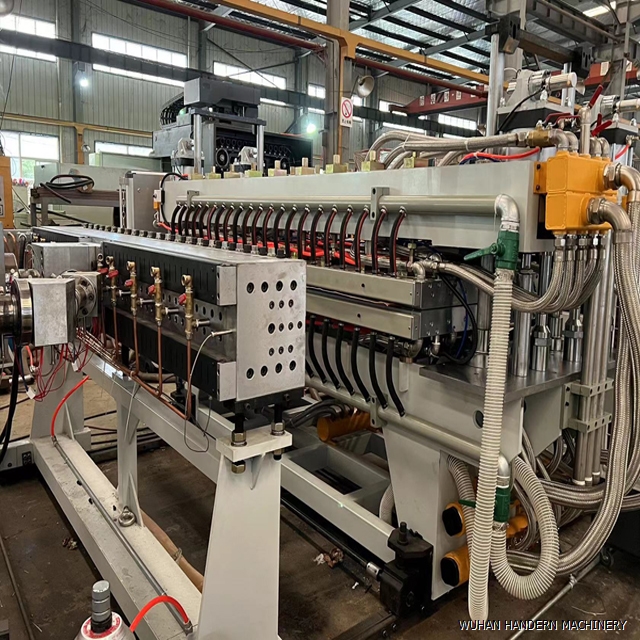

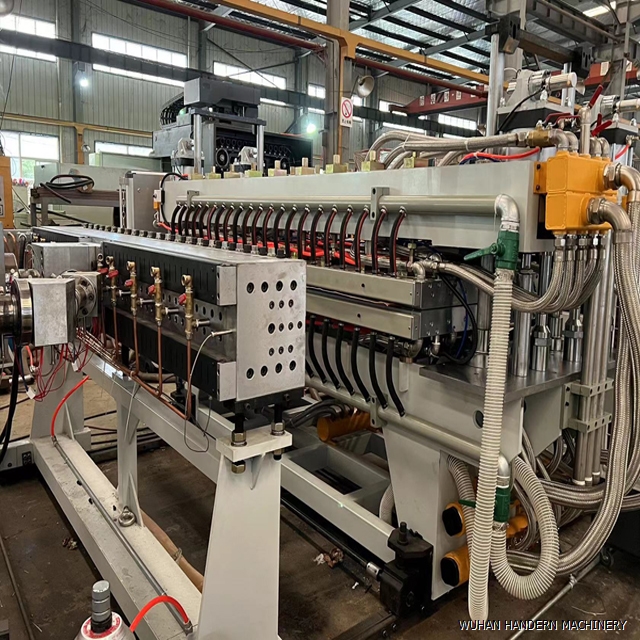

Before delivery, the PP hollow board equipment needs to undergo acceptance work with the customer to ensure that the factory equipment can meet the customer's production requirements. When inspecting the PP hollow board equipment, we need to check multiple places to ensure that the equipment has been fully inspected. Below, the editor will introduce in detail several important acceptance points for PP hollow board equipment:

1. Equipment appearance inspection

1. Equipment appearance inspection

During equipment acceptance, the first step is to conduct a comprehensive inspection of the appearance of the equipment. Including whether there are scratches, dents, rust and other defects on the surface of the equipment, whether the connecting components are firm, and whether the infrastructure is stable. The integrity of the appearance directly affects the service life and maintenance costs of the equipment in the later stage.

2. Functional performance testing

The functionality and performance of the equipment are the most critical acceptance criteria. The following tests need to be conducted:

Production capacity: Check whether the production capacity of the equipment under rated conditions meets the customer's requirements, including the number and thickness of hollow boards produced per hour.

Stability: Observe the stability of the equipment during long-term operation or under different load conditions, and check for any abnormal vibrations or noise.

Temperature control: Verify whether the temperature control system of the equipment is flexible and accurate, especially for equipment involving processes such as melt extrusion.

3. Electrical system inspection

3. Electrical system inspection

The safety and stability of electrical systems are crucial for the normal operation of equipment. During acceptance, the following aspects need to be checked:

Wiring of electrical system: Ensure that all wiring is correct and there is no aging, loosening, or other issues.

Whether the protective devices are functioning properly, such as overload protection, temperature control protection, etc., to prevent damage or danger to the equipment in case of malfunction.

Operation of control system: Check whether the operation panel is clearly labeled, and whether various function switches and indicator lights are working properly.

4. Compatibility of materials and accessories

The production equipment for PP hollow boards needs to be compatible with the corresponding raw materials and auxiliary materials, so special attention should be paid during acceptance:

Adaptability of feeding system: Ensure that the feeding system can smoothly provide raw materials, including adaptability to materials of different particle sizes and shapes.

Molds and accessories: Whether the molds used meet the design requirements and whether they can produce hollow boards that meet the specifications.

5. Safety and Environmental Protection

5. Safety and Environmental Protection

The safety and environmental requirements of production equipment also need to be carefully inspected to ensure:

Whether the safety protection facilities equipped on the equipment, such as safety covers and emergency stop buttons, are complete and effective.

Exhaust gas and wastewater treatment system: Ensure that the equipment meets environmental standards and has the necessary exhaust gas and wastewater treatment capabilities.

If all five points above have been accepted, then the PP hollow board equipment is considered a qualified product and can be delivered to customers normally. If customers encounter problems in subsequent use, we will also provide technical guidance services.

During equipment acceptance, the first step is to conduct a comprehensive inspection of the appearance of the equipment. Including whether there are scratches, dents, rust and other defects on the surface of the equipment, whether the connecting components are firm, and whether the infrastructure is stable. The integrity of the appearance directly affects the service life and maintenance costs of the equipment in the later stage.

2. Functional performance testing

The functionality and performance of the equipment are the most critical acceptance criteria. The following tests need to be conducted:

Production capacity: Check whether the production capacity of the equipment under rated conditions meets the customer's requirements, including the number and thickness of hollow boards produced per hour.

Stability: Observe the stability of the equipment during long-term operation or under different load conditions, and check for any abnormal vibrations or noise.

Temperature control: Verify whether the temperature control system of the equipment is flexible and accurate, especially for equipment involving processes such as melt extrusion.

The safety and stability of electrical systems are crucial for the normal operation of equipment. During acceptance, the following aspects need to be checked:

Wiring of electrical system: Ensure that all wiring is correct and there is no aging, loosening, or other issues.

Whether the protective devices are functioning properly, such as overload protection, temperature control protection, etc., to prevent damage or danger to the equipment in case of malfunction.

Operation of control system: Check whether the operation panel is clearly labeled, and whether various function switches and indicator lights are working properly.

4. Compatibility of materials and accessories

The production equipment for PP hollow boards needs to be compatible with the corresponding raw materials and auxiliary materials, so special attention should be paid during acceptance:

Adaptability of feeding system: Ensure that the feeding system can smoothly provide raw materials, including adaptability to materials of different particle sizes and shapes.

Molds and accessories: Whether the molds used meet the design requirements and whether they can produce hollow boards that meet the specifications.

The safety and environmental requirements of production equipment also need to be carefully inspected to ensure:

Whether the safety protection facilities equipped on the equipment, such as safety covers and emergency stop buttons, are complete and effective.

Exhaust gas and wastewater treatment system: Ensure that the equipment meets environmental standards and has the necessary exhaust gas and wastewater treatment capabilities.

If all five points above have been accepted, then the PP hollow board equipment is considered a qualified product and can be delivered to customers normally. If customers encounter problems in subsequent use, we will also provide technical guidance services.

Author:admin