Solve the mystery for you on the biaxial stretching film test line

DATE:2024/8/5 15:03:01 / READ: / SOURCE:This station

The Bi directional stretch film production line can stretch the film in both longitudinal and transverse directions, ensuring that the molecular chains of the film are uniformly arranged in both directions, resulting in significant improvements in strength, ductility, and glossiness. Currently, the films that require biaxially stretched technology for production mainly include BOPP BOPET、BOPLA、BOPA、BOPS, And some special purpose optical films, whose main application areas include packaging, electronics, medical and other fields.

In addition, the Bi directional stretch film production line can also optimize the production process by controlling different stretching ratios, temperature, and time parameters to experiment with the effects of different conditions on film properties. At present, the content of the testing line mainly includes two aspects. One is the testing of physical properties, including the tear resistance, tensile strength, and toughness of the film, to ensure that the product can meet the standards in practical applications; The second is surface treatment testing, which is used to evaluate the printing adaptability and adhesion of the film, ensuring its performance in subsequent printing and processing.

The composition structure of the Bi directional stretch film production line is relatively complex. It is assembled from multiple key components, and through the close cooperation of each component, qualified biaxially stretched films can be produced smoothly. The composition and structure of the Bi directional stretch film production line include:

Extruder: used to melt and extrude plastic raw materials into thin films. If transparent plastic particles such as polypropylene (PP) or polyethylene terephthalate (PET) are used, the transparency of the film can be further enhanced.

Stretching machine: Stretching the film in two directions to achieve the desired physical properties. Stretching machines are usually equipped with temperature control systems to ensure that the film is stretched at an appropriate temperature and improve the stretching effect.

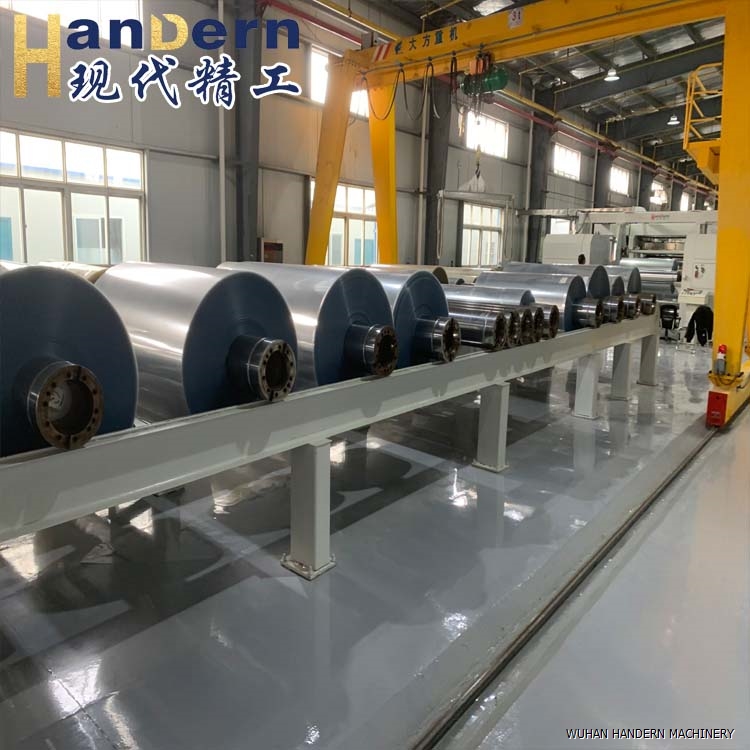

Cooling system: The stretched film needs to be rapidly cooled to consolidate its stretched state, usually using cooling rollers or a water spray system.

Rolling device: Roll up the finished film for subsequent transportation and storage.

With the increasing demand for environmental protection and performance, the market demand for double pull films is continuously growing, and the application scope of such double pull films is gradually expanding, from food packaging to high-tech electronic components. I believe that as the functionality of the biaxially stretched film testing line becomes more and more complete, it will be able to produce more types of films, and its film performance will be greatly improved. Its future development potential is enormous.

Author:admin