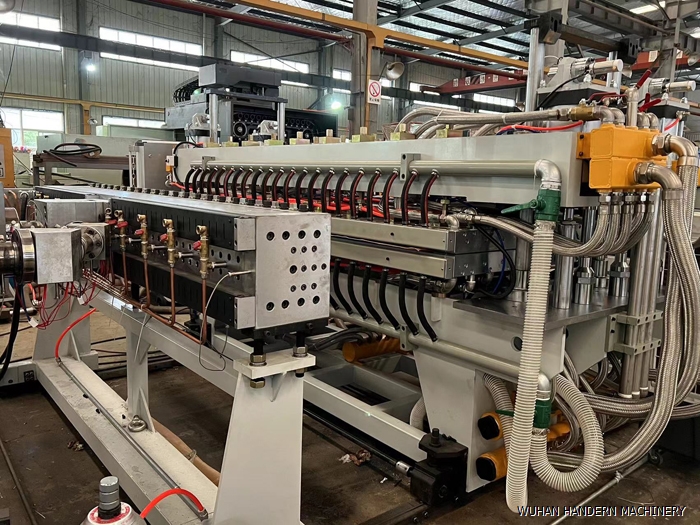

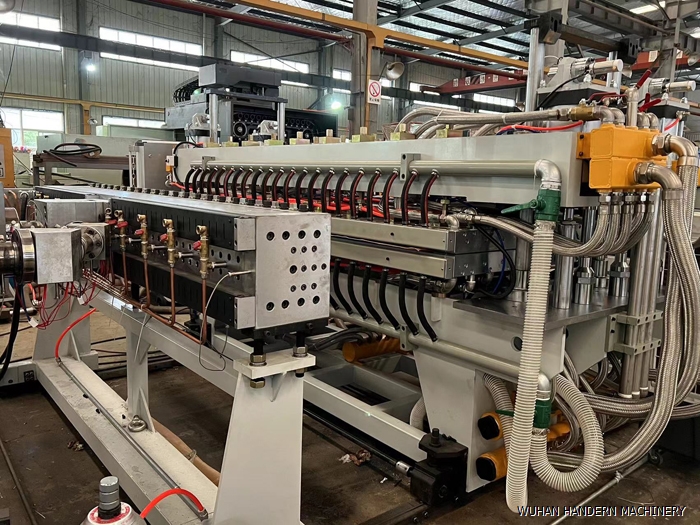

Introduction to the working principle and advantages of the twin screw hollow sheet production line

DATE:2024/7/10 15:45:05 / READ: / SOURCE:This station

The twin screw hollow sheet production line is a commonly used production equipment, which works mainly by mixing, squeezing, and forming raw materials through two rotating screws, and finally producing hollow plate products. The workflow of the twin screw hollow sheet production line can be roughly divided into the following steps:

Firstly, the raw materials are added to the feed inlet of the production line, and through the mixing and extrusion action of the screw, the raw materials gradually deform and are heated. During this process, the raw materials are continuously squeezed and pushed, forming a uniform mixture.

Next, the mixture is molded through a mold, cooled and cured to form a hollow board product.

Next, the mixture is molded through a mold, cooled and cured to form a hollow board product.

The advantages of the twin screw hollow sheet production line are mainly reflected in the following aspects:

1. High production efficiency: The twin screw hollow sheet production line adopts automated production, which can quickly complete production tasks and improve production efficiency.

2. Stable product quality: Due to the use of advanced production technology in the twin screw hollow sheet production line, it can ensure stable and consistent product quality.

3. Energy saving: The twin screw hollow sheet production line adopts energy-saving technology, which can effectively reduce energy consumption and save production costs.

3. Energy saving: The twin screw hollow sheet production line adopts energy-saving technology, which can effectively reduce energy consumption and save production costs.

4. Strong versatility: The twin screw hollow sheet production line can not only produce hollow plate products, but also produce other shaped products according to needs, with strong versatility.

Overall, the twin screw hollow sheet production line has become the preferred production equipment for many production enterprises due to its advantages of high efficiency, stability, energy conservation, and multifunctionality.

Overall, the twin screw hollow sheet production line has become the preferred production equipment for many production enterprises due to its advantages of high efficiency, stability, energy conservation, and multifunctionality.

Firstly, the raw materials are added to the feed inlet of the production line, and through the mixing and extrusion action of the screw, the raw materials gradually deform and are heated. During this process, the raw materials are continuously squeezed and pushed, forming a uniform mixture.

The advantages of the twin screw hollow sheet production line are mainly reflected in the following aspects:

1. High production efficiency: The twin screw hollow sheet production line adopts automated production, which can quickly complete production tasks and improve production efficiency.

2. Stable product quality: Due to the use of advanced production technology in the twin screw hollow sheet production line, it can ensure stable and consistent product quality.

4. Strong versatility: The twin screw hollow sheet production line can not only produce hollow plate products, but also produce other shaped products according to needs, with strong versatility.

Author:admin