What are the process difficulties of the biaxially stretched film production line

DATE:2023/8/25 9:56:13 / READ: / SOURCE:This station

The biaxial stretching film production line is a device used for producing polyester film, mainly used in fields such as food packaging, medical applications, and electronic product protection. In the industry, there are also some nicknames for biaxial stretching film production lines, such as biaxial stretching film machines, biaxial stretching film machines, etc. The process difficulty of the biaxially stretched film production line is very high, which is also the reason why there are currently few factories in China with the ability to produce this type of production line. Below, the editor will provide a detailed introduction to the specific process difficulties of the biaxial stretching film production line.

Secondly, the control of stretching process is also one of the difficulties in biaxial stretching film production lines. The stretching process refers to the process of evenly stretching polyester sheets in two directions through stretching, in order to obtain a certain stretching ratio. During the stretching process, it is necessary to control parameters such as stretching speed, temperature, and stretching ratio to ensure the uniformity and stability of the product's stretching. High or low stretching speed and temperature can affect the quality and performance of products, therefore, precise control of stretching process is the key to ensuring product quality.

Temperature control is also an important process difficulty in biaxially stretched film production lines. Temperature plays a crucial role in the entire production process, directly affecting the physical properties and appearance quality of products. During the production process, it is necessary to control parameters such as hot air temperature and roller temperature to ensure temperature uniformity and stability during material melting and stretching. Whether the temperature is too high or too low can lead to product quality issues, therefore precise temperature control is the key to ensuring product quality.

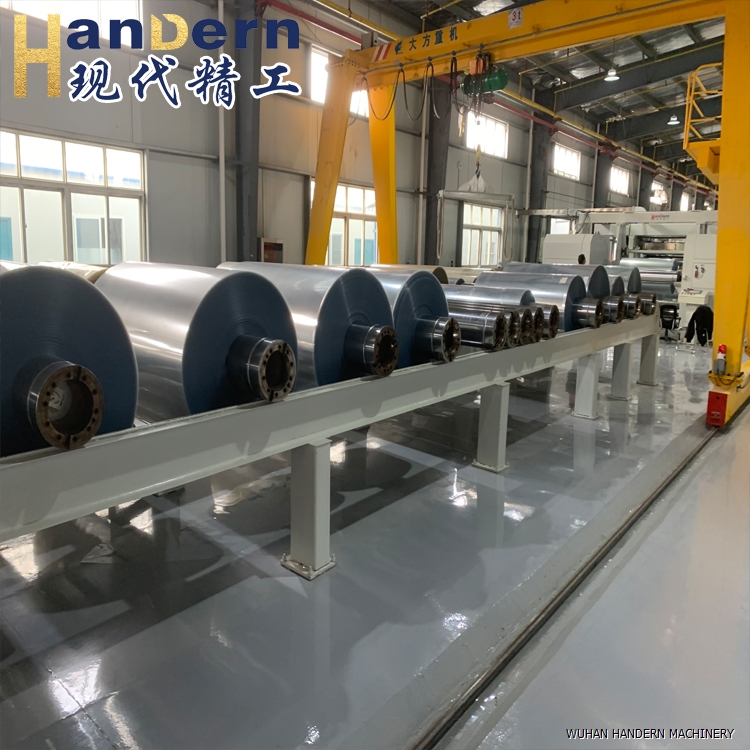

Roller adjustment is another key process difficulty in the biaxial stretching film production line. The roller plays a guiding and supporting role in the production line, and has a significant impact on the uniformity of product stretching and thickness control. During the production process, it is necessary to adjust the position and pressure of the rollers to ensure uniform stretching and thickness control of the material during the stretching process. Inaccurate roller adjustment can lead to uneven thickness and stretching of the product, affecting the quality of the product.

Finally, film winding is the last process step in the biaxial stretching film production line and also a key process difficulty. The quality of film winding and appearance directly affect the product's coiling and user experience. During the winding process, it is necessary to control parameters such as winding tension and speed to ensure the flatness and coiling quality of the film. Excessive or insufficient coiling tension can lead to uneven coiling of the film, affecting the quality of the product.

In summary, the process difficulties of the biaxial stretching film production line mainly include material selection, stretching process control, temperature control, roller adjustment, and film winding. Only by overcoming these difficulties and accurately controlling process parameters can we produce bi-directional stretched film products with stable quality and excellent performance, meeting market demand.

Author:admin