Introduction and Process Explanation of PEVA Embossed Composite Film

DATE:2023/8/14 14:19:14 / READ: / SOURCE:This station

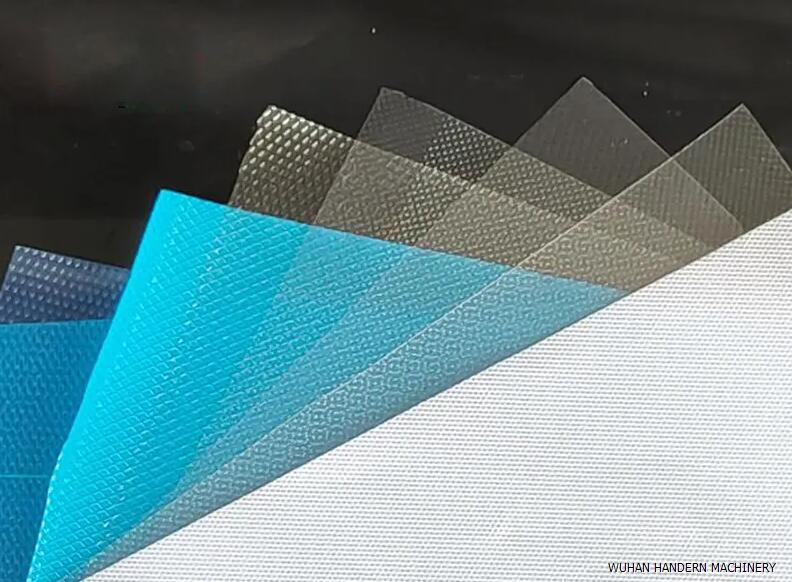

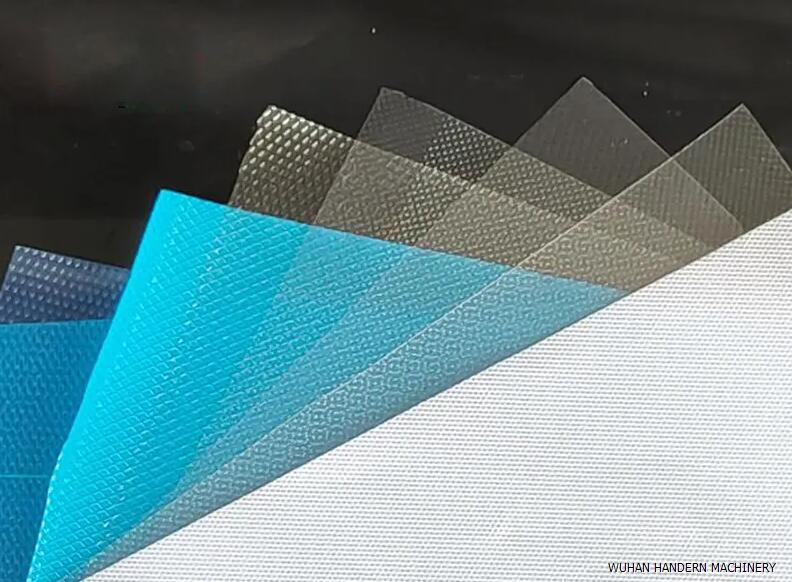

PEVA embossed composite film is a common composite material composed of polyethylene vinyl acetate (PEVA) and other materials. PEVA embossed composite film has a wide range of applications in many fields, and its role and production process are very important.

Firstly, let's understand the role of PEVA embossed composite film. PEVA embossed composite film has excellent waterproof and wear-resistant properties, which can effectively protect items from moisture and wear. Therefore, it is often used to make various packaging materials, such as bags, boxes, packaging films, etc. In the food industry, PEVA embossed composite film is also commonly used to make food preservation bags, which can effectively maintain the freshness and quality of food. In addition, PEVA embossed composite film also has a certain degree of transparency and softness, which can be used to make products such as raincoats and shower curtains.

Firstly, let's understand the role of PEVA embossed composite film. PEVA embossed composite film has excellent waterproof and wear-resistant properties, which can effectively protect items from moisture and wear. Therefore, it is often used to make various packaging materials, such as bags, boxes, packaging films, etc. In the food industry, PEVA embossed composite film is also commonly used to make food preservation bags, which can effectively maintain the freshness and quality of food. In addition, PEVA embossed composite film also has a certain degree of transparency and softness, which can be used to make products such as raincoats and shower curtains.

Next, let's learn about the production process of PEVA embossed composite film. The production process of PEVA embossed composite film mainly includes the following steps:

1. Raw material preparation: Firstly, it is necessary to prepare raw materials for PEVA and other composite materials. PEVA is a thermoplastic material that can be made into thin films by melting and extrusion. Other composite materials can be selected according to needs, such as polyethylene (PE), polypropylene (PP), etc.

2. Extrusion: After mixing PEVA and other composite materials in a certain proportion, the mixture is melted and extruded into a thin film shape through an extruder. The extruder heats the mixture to a certain temperature, causing it to melt and form a continuous film.

3. Embossing: The extruded film is embossed using an embossing machine. The embossing machine usually has a pair of rollers, one of which has a texture on it. When the film passes through the roller, the texture will be pressed into the surface of the film, forming an embossing effect.

4. Composite: Composite the embossed PEVA film with other composite materials. There are many ways to composite, such as hot pressing composite, hot melting composite, etc. The purpose of composite is to combine the characteristics of different materials and improve the overall performance.

5. Production of products: After the composite is completed, the PEVA embossed composite film can be cut, cut, and edge sealed as needed to produce products of different shapes and sizes.

It should be noted that the production process of PEVA embossed composite film may vary depending on different manufacturers and products, and the above steps are only a general production process. In actual production, adjustments and improvements need to be made according to the requirements of the product.

In summary, PEVA embossed composite film plays an important role in packaging, preservation, and waterproofing. The production process includes steps such as raw material preparation, extrusion, embossing, lamination, and product production. With the continuous development of technology, the application fields and production processes of PEVA embossed composite films will continue to expand and improve, providing better solutions for various industries.

Next, let's learn about the production process of PEVA embossed composite film. The production process of PEVA embossed composite film mainly includes the following steps:

1. Raw material preparation: Firstly, it is necessary to prepare raw materials for PEVA and other composite materials. PEVA is a thermoplastic material that can be made into thin films by melting and extrusion. Other composite materials can be selected according to needs, such as polyethylene (PE), polypropylene (PP), etc.

2. Extrusion: After mixing PEVA and other composite materials in a certain proportion, the mixture is melted and extruded into a thin film shape through an extruder. The extruder heats the mixture to a certain temperature, causing it to melt and form a continuous film.

3. Embossing: The extruded film is embossed using an embossing machine. The embossing machine usually has a pair of rollers, one of which has a texture on it. When the film passes through the roller, the texture will be pressed into the surface of the film, forming an embossing effect.

4. Composite: Composite the embossed PEVA film with other composite materials. There are many ways to composite, such as hot pressing composite, hot melting composite, etc. The purpose of composite is to combine the characteristics of different materials and improve the overall performance.

5. Production of products: After the composite is completed, the PEVA embossed composite film can be cut, cut, and edge sealed as needed to produce products of different shapes and sizes.

It should be noted that the production process of PEVA embossed composite film may vary depending on different manufacturers and products, and the above steps are only a general production process. In actual production, adjustments and improvements need to be made according to the requirements of the product.

In summary, PEVA embossed composite film plays an important role in packaging, preservation, and waterproofing. The production process includes steps such as raw material preparation, extrusion, embossing, lamination, and product production. With the continuous development of technology, the application fields and production processes of PEVA embossed composite films will continue to expand and improve, providing better solutions for various industries.

Author:admin