What is the MDO unidirectional stretching production line

DATE:2023/6/30 14:04:47 / READ: / SOURCE:This station

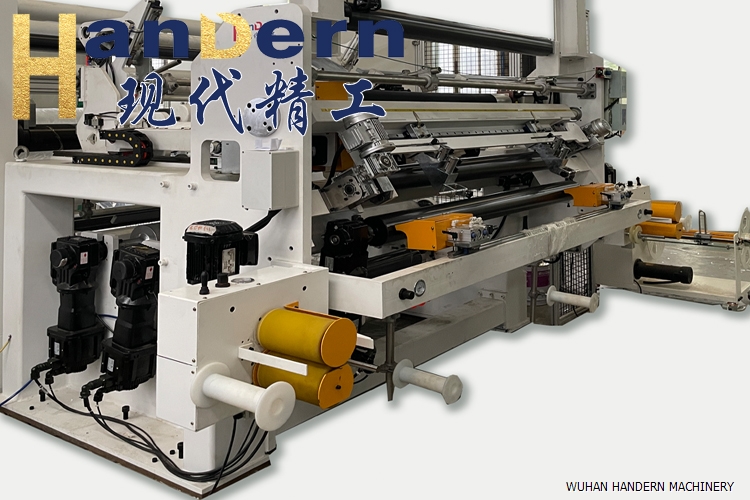

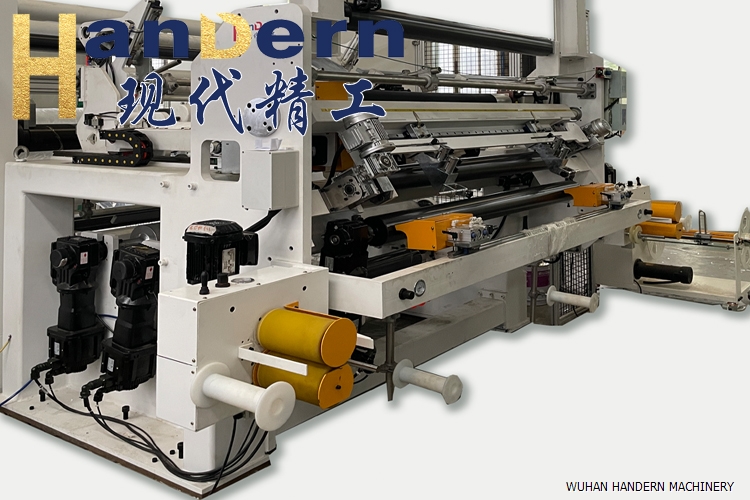

MDO Machine Direction Orientation is a commonly used plastic processing technology used to improve the mechanical and physical properties of plastic films. The MDO unidirectional stretching production line is a specialized equipment for conducting MDO unidirectional stretching. Its working principle is to arrange plastic films in an orderly manner in the mechanical direction through stretching and heating, thereby improving their tensile strength, stiffness, and transparency.

The MDO unidirectional stretching production line mainly consists of stretching machines, heating systems, cooling systems, control systems, etc. Firstly, the prefabricated plastic film is fed into the stretching machine, and the plastic film is stretched mechanically through the action of rollers. During the stretching process, the heating system heats the plastic film, making it more prone to orderly arrangement during the stretching process. After stretching, the plastic film is quickly cooled through a cooling system to fix its stretched structure. Finally, the control system monitors and controls the entire stretching process to ensure the stability and consistency of the stretching effect.

The MDO unidirectional stretching production line mainly consists of stretching machines, heating systems, cooling systems, control systems, etc. Firstly, the prefabricated plastic film is fed into the stretching machine, and the plastic film is stretched mechanically through the action of rollers. During the stretching process, the heating system heats the plastic film, making it more prone to orderly arrangement during the stretching process. After stretching, the plastic film is quickly cooled through a cooling system to fix its stretched structure. Finally, the control system monitors and controls the entire stretching process to ensure the stability and consistency of the stretching effect.

The MDO unidirectional stretching production line has a wide range of applications and can be used to produce various plastic films, such as polyethylene film, polypropylene film, polyester film, etc. These plastic films are widely used in packaging, construction, agriculture, medical and other fields. For example, polyethylene film can be used to make food packaging bags, shopping bags, etc; Polypropylene film can be used to make battery separators, textile packaging bags, etc; Polyester film can be used to make optical films, electronic product films, etc.

The MDO unidirectional stretching production line has many advantages. Firstly, through MDO unidirectional stretching, the tensile strength and stiffness of plastic films can be significantly improved, making them more durable and stable. Secondly, MDO unidirectional stretching can also improve the transparency and glossiness of plastic films, making them more attractive and commercially valuable. In addition, MDO unidirectional stretching can also improve the heat sealing and printing properties of plastic films, and improve the processing and usability of products. Finally, the MDO unidirectional stretching production line has the characteristics of high efficiency and high degree of automation, which can significantly improve production efficiency and reduce production costs.

In summary, the MDO unidirectional stretching production line is an important plastic processing equipment that improves the performance of plastic films through stretching and heating. It has a wide range of applications and obvious advantages, which can improve the mechanical, physical, and processing properties of plastic films and meet the needs of different fields. With the continuous development of technology, the MDO unidirectional stretching production line will play an increasingly important role in the plastic processing industry.

The MDO unidirectional stretching production line has a wide range of applications and can be used to produce various plastic films, such as polyethylene film, polypropylene film, polyester film, etc. These plastic films are widely used in packaging, construction, agriculture, medical and other fields. For example, polyethylene film can be used to make food packaging bags, shopping bags, etc; Polypropylene film can be used to make battery separators, textile packaging bags, etc; Polyester film can be used to make optical films, electronic product films, etc.

The MDO unidirectional stretching production line has many advantages. Firstly, through MDO unidirectional stretching, the tensile strength and stiffness of plastic films can be significantly improved, making them more durable and stable. Secondly, MDO unidirectional stretching can also improve the transparency and glossiness of plastic films, making them more attractive and commercially valuable. In addition, MDO unidirectional stretching can also improve the heat sealing and printing properties of plastic films, and improve the processing and usability of products. Finally, the MDO unidirectional stretching production line has the characteristics of high efficiency and high degree of automation, which can significantly improve production efficiency and reduce production costs.

In summary, the MDO unidirectional stretching production line is an important plastic processing equipment that improves the performance of plastic films through stretching and heating. It has a wide range of applications and obvious advantages, which can improve the mechanical, physical, and processing properties of plastic films and meet the needs of different fields. With the continuous development of technology, the MDO unidirectional stretching production line will play an increasingly important role in the plastic processing industry.

Author:admin