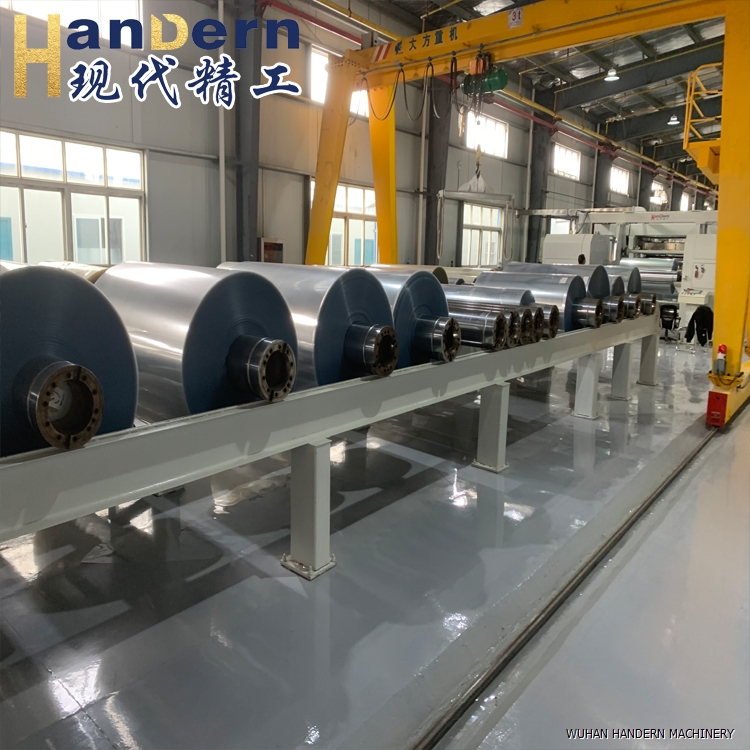

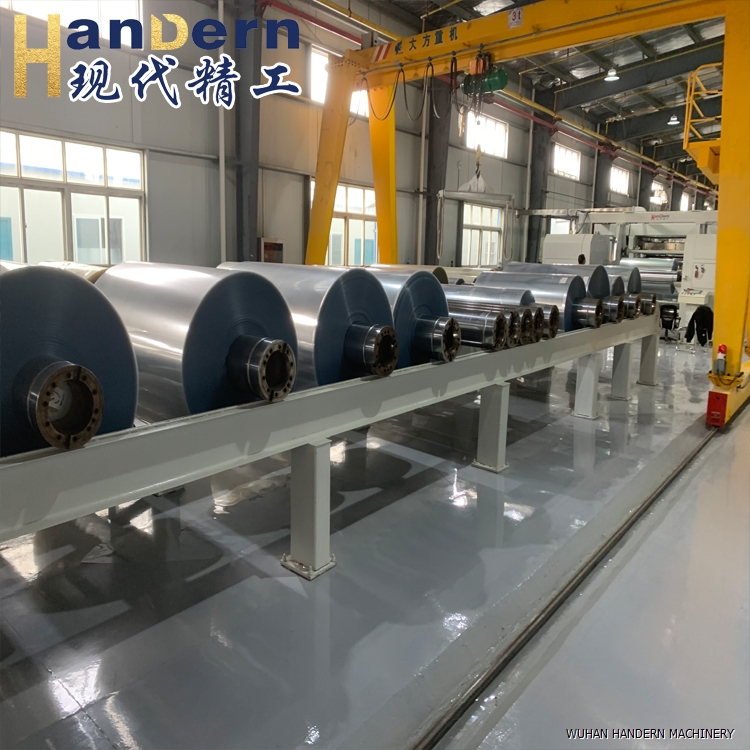

Comprehensive interpretation of what is a biaxially stretched film production line

DATE:2023/6/27 14:36:09 / READ: / SOURCE:This station

The biaxially stretched film production line adopts biaxial stretching technology, which can stretch the film in two directions simultaneously, resulting in better physical properties and appearance quality. Biaxially stretched films are required in many industries with high requirements for films.

1、 Introduction to the Biaxial Stretch Film Production Line

1、 Introduction to the Biaxial Stretch Film Production Line

The biaxial stretching film production line is an equipment used to produce high-strength, high transparency, and high toughness films. It adopts biaxial stretching technology, which allows the film to stretch in both directions simultaneously, resulting in better physical properties and appearance quality. Biaxially stretched films are widely used in fields such as food packaging, pharmaceutical packaging, electronic product packaging, building materials, and agricultural coverage.

2、 Working principle of biaxial stretching film production line

The working principle of a biaxially stretched film production line is to first heat the raw material (usually polypropylene or polyethylene) to a molten state, and then extrude the melted raw material into a film through an extruder. Next, the film will undergo a series of pre-treatment processes, such as cooling, width setting, longitudinal stretching, etc., and finally enter the biaxial stretching unit. In a biaxial stretching machine, the film is stretched simultaneously in both directions, making it more uniform, transparent, and more resilient. Finally, the film will become the final product through processes such as cooling, cutting, and coiling.

3、 Applicable scope of biaxially stretched film production line

The application range of the biaxial stretching film production line is very wide, and it can produce various types of films, such as polypropylene film, polyethylene film, polyester film, etc. These films can be used in fields such as food packaging, pharmaceutical packaging, electronic product packaging, building materials, and agricultural coverage. Due to the characteristics of high strength, high transparency, and high toughness, biaxially stretched films have been widely used in the above fields.

4、 Input cost of biaxially stretched film production line

The investment cost of the biaxial stretching film production line is relatively high, and factors such as equipment price, production cost, and labor cost need to be considered. The price of the equipment itself depends on the size and configuration of the production line, and generally speaking, larger production lines will have higher prices. Production costs include raw material costs, energy costs, maintenance costs, etc. The labor cost depends on the degree of automation and work efficiency of the production line. Overall, the investment cost of the biaxially stretched film production line is relatively high and requires careful consideration.

The biaxially stretched film production line is an efficient and high-quality equipment for producing films, with broad application prospects. When using a biaxially stretched film production line, it is necessary to pay attention to factors such as equipment scale and configuration, production costs, and labor costs to ensure the economic benefits and production quality of the production line.

The biaxially stretched film production line is an efficient and high-quality equipment for producing films, with broad application prospects. When using a biaxially stretched film production line, it is necessary to pay attention to factors such as equipment scale and configuration, production costs, and labor costs to ensure the economic benefits and production quality of the production line.

The biaxial stretching film production line is an equipment used to produce high-strength, high transparency, and high toughness films. It adopts biaxial stretching technology, which allows the film to stretch in both directions simultaneously, resulting in better physical properties and appearance quality. Biaxially stretched films are widely used in fields such as food packaging, pharmaceutical packaging, electronic product packaging, building materials, and agricultural coverage.

2、 Working principle of biaxial stretching film production line

The working principle of a biaxially stretched film production line is to first heat the raw material (usually polypropylene or polyethylene) to a molten state, and then extrude the melted raw material into a film through an extruder. Next, the film will undergo a series of pre-treatment processes, such as cooling, width setting, longitudinal stretching, etc., and finally enter the biaxial stretching unit. In a biaxial stretching machine, the film is stretched simultaneously in both directions, making it more uniform, transparent, and more resilient. Finally, the film will become the final product through processes such as cooling, cutting, and coiling.

3、 Applicable scope of biaxially stretched film production line

The application range of the biaxial stretching film production line is very wide, and it can produce various types of films, such as polypropylene film, polyethylene film, polyester film, etc. These films can be used in fields such as food packaging, pharmaceutical packaging, electronic product packaging, building materials, and agricultural coverage. Due to the characteristics of high strength, high transparency, and high toughness, biaxially stretched films have been widely used in the above fields.

4、 Input cost of biaxially stretched film production line

The investment cost of the biaxial stretching film production line is relatively high, and factors such as equipment price, production cost, and labor cost need to be considered. The price of the equipment itself depends on the size and configuration of the production line, and generally speaking, larger production lines will have higher prices. Production costs include raw material costs, energy costs, maintenance costs, etc. The labor cost depends on the degree of automation and work efficiency of the production line. Overall, the investment cost of the biaxially stretched film production line is relatively high and requires careful consideration.

Author:admin