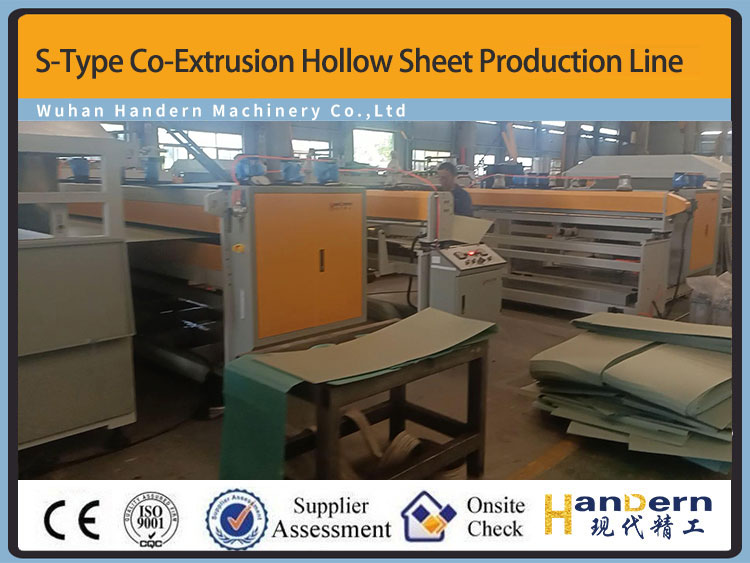

This advanced production line specializes in manufacturing high-performance hollow sheets through S-type co-extrusion technology, ideal for lightweight yet durable applications in construction, advertising, and packaging industries. By layering multiple polymer materials simultaneously, it ensures enhanced strength, UV resistance, and thermal stability.

The S-type design optimizes material distribution and structural integrity, reducing warping while improving energy efficiency. Compatible with PP, PVC, and PE, the line supports customizable thicknesses and widths, meeting diverse industrial demands. With automated control and precision extrusion, it guarantees consistent quality and high output, making it a cost-effective solution for eco-friendly and long-lasting hollow sheet production.

Contact US

Wuhan Handern Machinery Co.,Ltd

Wuhan Handern Machinery Co.,Ltd